machine screw vs self tapping pricelist

Comparing Machine Screws and Self-Tapping Screws A Price Perspective

When it comes to fastening materials in construction, manufacturing, or DIY projects, screws play an essential role. Among the plethora of options available, machine screws and self-tapping screws are two of the most commonly used varieties. While both serve the fundamental purpose of joining materials, they differ significantly in design, application, and pricing. Understanding these differences is crucial for any buyer looking to make informed decisions based on their specific project requirements and budget constraints.

Machine Screws Definition and Usage

Machine screws are cylindrical fasteners with uniform diameters and flat heads, designed to be inserted into pre-tapped holes or used with nuts. These screws are ideal for a variety of applications, particularly when joining components that must be frequently disassembled or have precise alignment. The materials used for machine screws can vary from stainless steel to brass, and they are available in numerous sizes and thread patterns.

From a price standpoint, machine screws tend to be moderately priced, influenced by factors such as material type, coating, and manufacturer. Bulk purchasing often brings down costs, making machine screws an economical choice for larger projects. However, their need for pre-tapped holes can increase labor costs and time, as additional steps are necessary for installation.

Self-Tapping Screws Definition and Usage

In contrast, self-tapping screws are designed to create their own holes in materials without the need for a pre-tapped hole. This feature allows them to be driven directly into wood, metal, or plastic, making them a favorite in various applications, from household furniture assembly to automotive manufacturing. The unique design of these screws includes a sharp point and wide threads that cut into the material while being driven, which enhances their holding power.

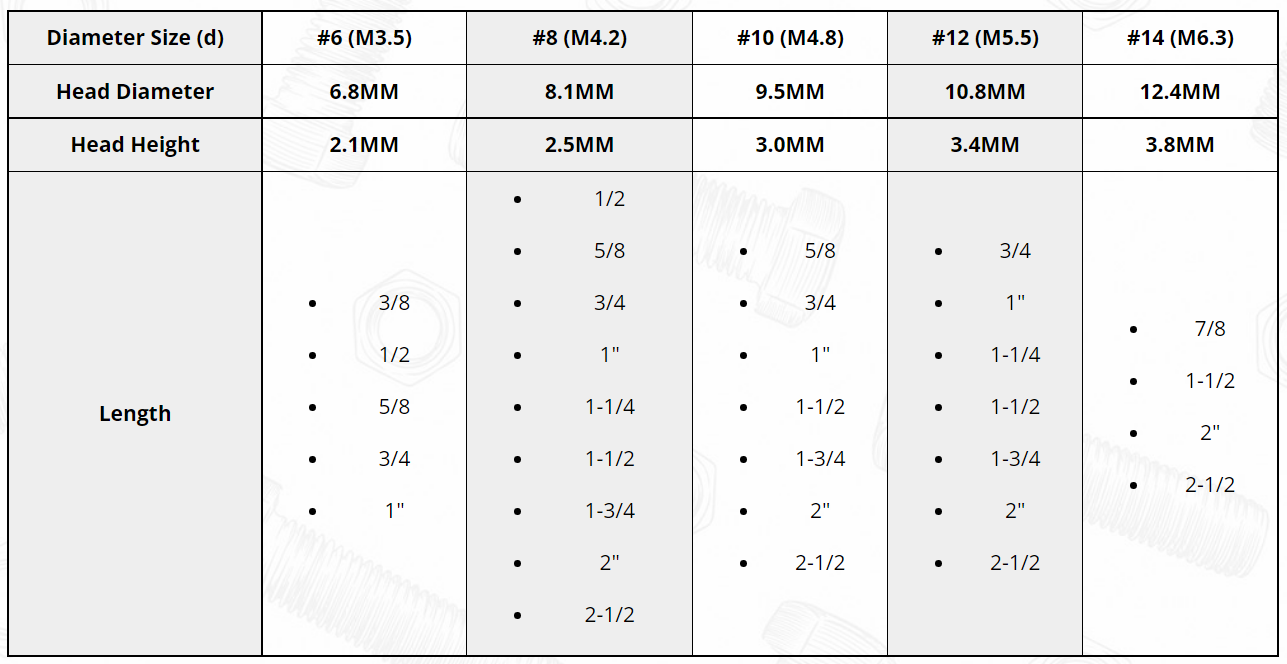

machine screw vs self tapping pricelist

When it comes to pricing, self-tapping screws are generally less expensive than machine screws, primarily because they eliminate the need for additional hardware like nuts and washers

. Their easy installation translates to reduced labor costs, making them a cost-effective option for many projects requiring rapid assembly.Price Comparison and Considerations

While both types of screws have their market segments, their pricing reflects their application and design characteristics. Typically, machine screws might range from $0.05 to $0.50 each, depending on the material and size, while self-tapping screws could start as low as $0.03 and go up to $0.30 each. It's worth noting that prices might fluctuate based on bulk orders, regional availability, and specific vendor pricing.

When choosing between machine screws and self-tapping screws, one must consider not only price but also the specific demands of the project. For high-stress applications requiring secure fastening and disassembly, machine screws paired with appropriate nuts are ideal despite a higher cost. On the other hand, for lower-stress applications where speed and ease of installation are priorities, self-tapping screws provide a more economical and efficient solution.

Conclusion

In conclusion, both machine screws and self-tapping screws are integral to various fastening tasks across industries. Understanding their differences in design, application, and price can help customers make better purchasing decisions aligned with their project needs. With the right choice, one can ensure that their project not only stays within budget but also meets the necessary safety and performance standards.

As with any fastener selection, it's advisable to consult with suppliers or manufacturers to explore options, pricing, and bulk purchase discounts. With the right information in hand, the decision between machine screws and self-tapping screws becomes clearer, leading to successful project completion. Whether you prioritize cost, ease of installation, or fastening strength, both categories of screws have something valuable to offer, effectively catering to a diverse range of fastening needs.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024