M8 Self Tapping Screw Size Specifications and Supplier Information

Understanding M8 Self-Tapping Screw Dimensions and Suppliers

Self-tapping screws are essential fasteners in various applications, allowing for ease of installation and a secure hold without requiring pre-drilled holes. Among the numerous types available, the M8 self-tapping screw stands out for its versatility and strength. In this article, we will discuss the dimensions of M8 self-tapping screws and provide guidance on sourcing reliable suppliers.

What is an M8 Self-Tapping Screw?

The M in M8 signifies the metric thread, while 8 indicates the nominal diameter of the screw shaft, which is 8 mm. Self-tapping screws are designed to create their own thread in the material they are being driven into, making them particularly useful for materials like metal, plastic, and wood. The M8 self-tapping screw, due to its larger diameter, is suitable for applications requiring a robust fastening solution.

Dimensions of M8 Self-Tapping Screws

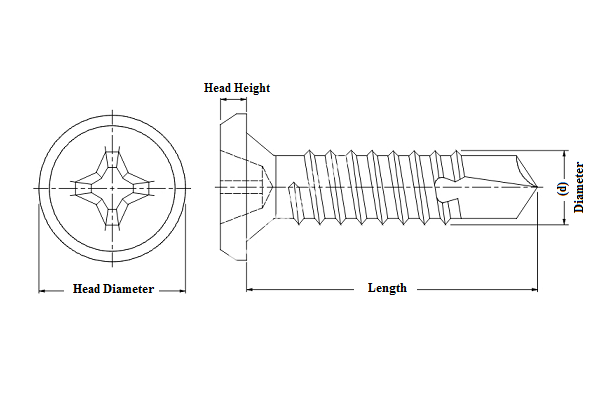

M8 self-tapping screws come with specific dimensions that dictate their performance. The key dimensions include

1. Diameter As mentioned, the nominal diameter is 8 mm. This is crucial for ensuring the correct fit in pre-existing holes or when creating new threads.

2. Length M8 self-tapping screws are available in various lengths, commonly ranging from 20 mm to 100 mm or more. The appropriate length will depend on the thickness of the materials being joined.

3. Thread Pitch The standard pitch for M8 screws is usually 1.25 mm, which is the distance between threads. This pitch ensures a stable grip when the screw is fastened into the material.

4. Head Type M8 self-tapping screws come in various head types, including pan, flat, and round. The choice of head type affects the screw's aesthetic and the way it interfaces with materials.

m8 self tapping screw dimensions supplier

5. Finish and Coating These screws can also come with different finishes, such as zinc-plated or black oxide, which enhance corrosion resistance and durability, depending on the application.

Sourcing M8 Self-Tapping Screws

When looking to purchase M8 self-tapping screws, it is essential to consider several factors to ensure you are obtaining quality products

1. Supplier Reputation Look for suppliers with a strong track record in the fastener industry. Established suppliers often have quality assurance measures in place to ensure their products meet international standards.

2. Quality Standards Ensure the screws comply with relevant quality standards, such as ISO or ANSI. High-quality screws are made from durable materials and undergo rigorous testing.

3. Customization Options Depending on the project, you may require specific dimensions or materials. Reliable suppliers often provide custom solutions tailored to your needs.

4. Bulk Availability For larger projects, seek suppliers that offer bulk purchasing options. This can lead to significant cost savings and ensure that you have a consistent supply.

5. Technical Support A good supplier should offer technical support to help you choose the right type of screw for your application. They can assist you in understanding the right specifications and dimensions according to your needs.

Conclusion

M8 self-tapping screws are vital components in various construction and manufacturing sectors. Understanding their dimensions—diameter, length, thread pitch, and type of head—is essential for choosing the right screw for your application. When sourcing these screws, focus on supplier reputation, quality standards, customization options, bulk availability, and technical support. By doing so, you will ensure that you obtain reliable fasteners that meet your project's specific requirements efficiently and effectively.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024