Mar . 05, 2025 02:42

Back to list

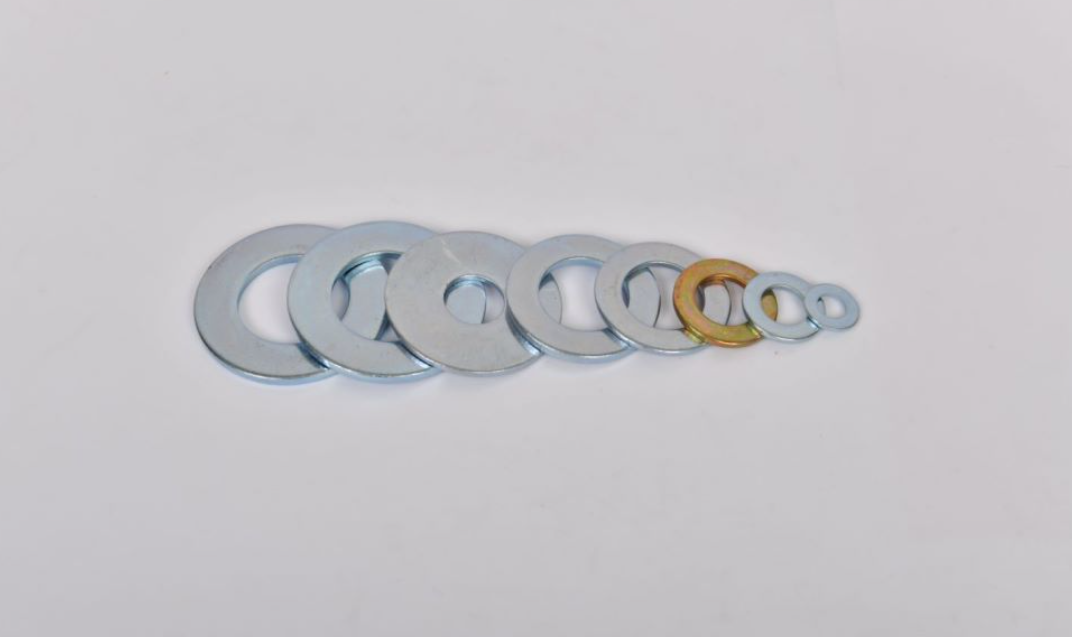

din125 plain washer flat washer

The M4 spring washer, though small and often overlooked in the grand scheme of mechanical components, plays an indispensable role in ensuring the longevity and efficiency of machinery across various industries. At first glance, it may seem like a simple device; however, its design and functionality provide crucial benefits that cannot be undervalued.

When installing an M4 spring washer, it is important to pair it with bolts or screws of the same material to avoid galvanic corrosion, which can occur when two different metals are in contact in a corrosive environment. Proper installation technique involves ensuring that the washer is placed on the correct side of the bolt – typically under the nut – to provide the best resistance to vibrational loss. Authoritative sources within the industry emphasize the critical nature of upkeep in high-vibration environments. Machine operators and maintenance personnel should be trained to recognize the signs of washer fatigue or damage, such as flattening or cracking. Regular inspections can preempt failure by allowing for timely replacements before mechanical failures occur. In addressing trustworthiness, manufacturers of M4 spring washers are expected to adhere to industry standards that govern material composition and manufacturing tolerances. This assurance is paramount for companies relying on these components to maintain operational safety and efficiency. Buyers should seek out washers produced by reputable manufacturers with certifications such as ISO 9001, ensuring adherence to quality management principles and customer satisfaction. The M4 spring washer is more than just a supplementary mechanical component; it is a critical factor in the durability and functionality of machines. By ensuring constant tension and preventing backlash, these washers enhance performance across myriad applications. Appreciating their value requires not only an understanding of their mechanical benefits but also a commitment to integrating them wisely across relevant industrial sectors. This holistic approach underscores the importance of reliable, well-crafted components like the M4 spring washer in building and maintaining the robust infrastructure that supports modern technology and industry.

When installing an M4 spring washer, it is important to pair it with bolts or screws of the same material to avoid galvanic corrosion, which can occur when two different metals are in contact in a corrosive environment. Proper installation technique involves ensuring that the washer is placed on the correct side of the bolt – typically under the nut – to provide the best resistance to vibrational loss. Authoritative sources within the industry emphasize the critical nature of upkeep in high-vibration environments. Machine operators and maintenance personnel should be trained to recognize the signs of washer fatigue or damage, such as flattening or cracking. Regular inspections can preempt failure by allowing for timely replacements before mechanical failures occur. In addressing trustworthiness, manufacturers of M4 spring washers are expected to adhere to industry standards that govern material composition and manufacturing tolerances. This assurance is paramount for companies relying on these components to maintain operational safety and efficiency. Buyers should seek out washers produced by reputable manufacturers with certifications such as ISO 9001, ensuring adherence to quality management principles and customer satisfaction. The M4 spring washer is more than just a supplementary mechanical component; it is a critical factor in the durability and functionality of machines. By ensuring constant tension and preventing backlash, these washers enhance performance across myriad applications. Appreciating their value requires not only an understanding of their mechanical benefits but also a commitment to integrating them wisely across relevant industrial sectors. This holistic approach underscores the importance of reliable, well-crafted components like the M4 spring washer in building and maintaining the robust infrastructure that supports modern technology and industry.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News