M3 Self-Tapping Screw Manufacturer for High-Quality Industrial Fastening Solutions

Exploring M3 Self-Tapping Screw Manufacturing A Deep Dive into Quality and Innovation

In the world of fasteners, M3 self-tapping screws represent a crucial component used across various industries, from construction to automotive and electronics. The evolution of manufacturing processes has revolutionized the production of these screws, ensuring they meet the most demanding standards of quality and performance. This article delves into the intricacies of M3 self-tapping screw factories, looking at manufacturing techniques, quality control measures, and the importance of innovation in today’s market.

Understanding M3 Self-Tapping Screws

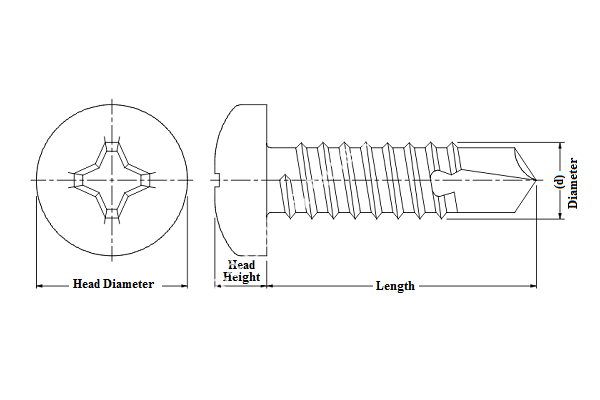

M3 self-tapping screws are characterized by their unique design, which allows them to create their own hole as they are driven into a material. This is achieved through specifically designed threads that cut into the substrate, making them ideal for applications where pre-drilling isn’t feasible. The M3 designation refers to the nominal diameter of the screw, which is 3mm, making them suitable for lightweight materials such as plastic, wood, and thin metals.

The Manufacturing Process

The manufacturing of M3 self-tapping screws involves several key steps, starting from the selection of raw materials to the final quality checks. Factories typically begin with high-grade steel wire, which is then precisely coated to enhance corrosion resistance. The production process can be broken down into several stages

1. Wire Drawing The steel is drawn through a series of dies to achieve the desired diameter. 2. Forming The wire undergoes forming processes where it is shaped into a screw head and threaded body. This step may include cold heading techniques that allow for precise geometry without losing material integrity.

3. Thread Rolling Threads are rolled onto the screw using cold forming techniques that improve strength through work hardening.

4. Heat Treatment This process enhances the mechanical properties of the screws, making them stronger and more durable.

5. Coating To prevent rust and improve aesthetics, screws are often coated using methods like zinc plating, black oxide, or other corrosion-resistant finishes.

Finally, screws undergo stringent quality control tests to ensure that they meet industry standards before being packaged for shipment.

m3 self tapping screw factory

Quality Control The Cornerstone of Reliability

Quality control is essential in the manufacturing of M3 self-tapping screws

. Factories implement rigorous testing protocols at various stages of production. These may include- Dimensional Inspections Ensuring that screws meet specified measurements regarding diameter, length, and thread pitch.

- Mechanical Testing Evaluating the tensile strength and hardness of the screws to ensure they can withstand the forces exerted on them in real-world applications.

- Corrosion Resistance Testing Subjecting screws to environmental tests to determine their performance in adverse conditions, aligning with industry regulations such as ASTM standards.

Through these measures, manufacturers can ensure that every batch of M3 self-tapping screws is of high quality, promoting safety and reliability in their applications.

Innovating for the Future

As industries evolve, so too must the manufacturing processes of M3 self-tapping screws. The incorporation of automation and advanced technology, such as computer numerical control (CNC) machining and real-time monitoring systems, has the potential to increase efficiency and precision in production.

Additionally, manufacturers are increasingly focused on sustainability, exploring eco-friendly materials and processes that reduce waste and energy consumption. These innovations not only improve the environmental footprint of production but also cater to an increasingly eco-conscious market.

Conclusion

The manufacturing of M3 self-tapping screws combines traditional craftsmanship with modern technology to produce reliable fasteners that are essential in many applications. By focusing on quality control and embracing innovation, factories are well-positioned to meet the demands of a rapidly changing industry landscape. As we look to the future, the M3 self-tapping screw will continue to be a pivotal element in ensuring the strength and durability of countless projects across various sectors.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024