m3 self tapping screw dimensions factory

Understanding M3 Self-Tapping Screw Dimensions and Their Importance

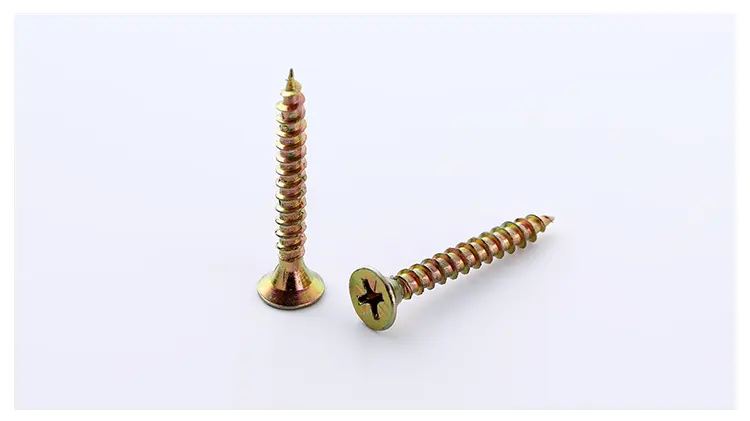

Self-tapping screws are essential fasteners used in various construction and manufacturing applications. Among these, the M3 self-tapping screw has gained popularity due to its versatile dimensions and usability. Understanding the dimensions and specifications of M3 self-tapping screws is crucial for selecting the right type for specific projects.

M3 self-tapping screws have a nominal diameter of 3 millimeters. This size is typically favored in scenarios where lightweight materials like plastics or thin sheets of metal are involved. The unique design of these screws allows them to create their own threads as they are driven into materials, eliminating the need for pre-drilled holes. This feature enhances efficiency and reduces assembly time, making them ideal for mass production environments.

When examining the dimensions of M3 self-tapping screws, several key factors come into play. The length of the screw is one of the most critical dimensions. M3 screws typically range from 6mm to 50mm in length, accommodating various application needs. It is essential to choose the appropriate length to ensure a secure fit without compromising the structural integrity of the materials being joined.

m3 self tapping screw dimensions factory

In addition to length, the thread pitch is another important specification. For M3 screws, the standard thread pitch is usually 0.5mm, which is suitable for most applications. However, some special variants exist with different pitches, providing further customization for specific needs. The thread type can be either coarse or fine, impacting the screw's grip and ability to penetrate materials.

The screw head design is also a significant aspect. M3 self-tapping screws come in various head styles, including pan, flat, and round heads. The choice of head style affects the screw's appearance and how well it sits flush against the surface being fastened. Additionally, the drive type, whether Phillips, slotted, or hex, influences ease of installation and the tools required.

Material selection is another factor that can affect the overall performance of M3 self-tapping screws. Common materials include stainless steel, carbon steel, and specialized alloys, each offering different levels of corrosion resistance and strength. For applications exposed to outdoor elements or harsh environments, stainless steel screws are often preferred due to their excellent resistance to rust and deterioration.

In conclusion, understanding the dimensions and characteristics of M3 self-tapping screws is vital for professionals in construction and manufacturing. By selecting the appropriate length, thread pitch, head style, and material, one can ensure a strong and durable connection in various applications. As industries continue to evolve, the importance of compatible and reliable fastening solutions like M3 self-tapping screws becomes increasingly significant. Thus, investing in quality screws from reputable factories can lead to successful project outcomes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024