m3 countersunk self tapping screw manufacturers

Understanding M3 Countersunk Self-Tapping Screw Manufacturers

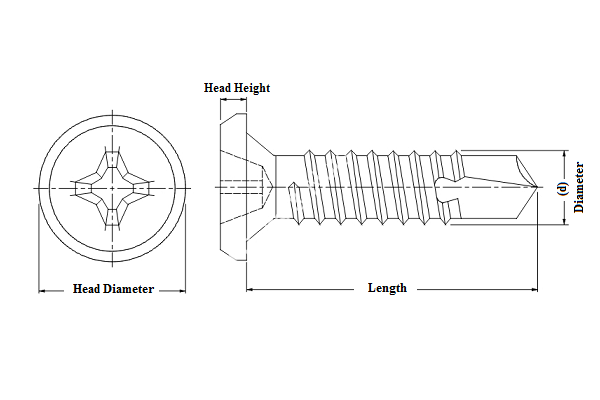

M3 countersunk self-tapping screws play a vital role in various industries due to their versatility and effectiveness in fastening materials together. The M3 designation refers to the screw's nominal diameter, which is 3 millimeters. These screws are designed to create their own hole as they are driven into materials like metal, plastic, or wood, making them a popular choice among manufacturers and DIY enthusiasts alike.

Design Features of M3 Countersunk Self-Tapping Screws

Countersunk screws are specifically designed with a flat head that allows them to sit flush with the surface of the material they are fastened into

. This feature not only provides a sleek finish but also reduces the risk of snagging or catching on surrounding materials, which is particularly important in applications such as furniture assembly, automotive components, and electronic housing.The self-tapping design is another significant advantage. Unlike traditional screws, which require a pre-drilled hole, self-tapping screws can penetrate the material directly, creating threads as they go. This not only simplifies the installation process but also reduces labor time and costs. The thread design varies among manufacturers, allowing for different applications, from Sheet Metal to more robust constructions.

The Role of Manufacturers

Manufacturers of M3 countersunk self-tapping screws are essential to ensuring that these fasteners meet quality standards and serve their intended purpose effectively. These companies focus on several aspects, including materials, design, production, and distribution.

1. Material Selection A critical factor for manufacturers is the choice of material. Common materials used include stainless steel, carbon steel, and various alloys. The choice impacts the screw's strength, corrosion resistance, and suitability for different environments. For example, stainless steel screws are ideal for outdoor applications or environments prone to moisture, as they resist rust and corrosion.

m3 countersunk self tapping screw manufacturers

2. Precision Engineering Manufacturing M3 countersunk self-tapping screws requires precision engineering to ensure they fit seamlessly into their intended applications. This includes maintaining consistent dimensions and surface finishes, as well as adhering to strict tolerances. Manufacturers often invest in state-of-the-art machinery and technology to achieve the desired levels of accuracy and quality.

3. Quality Control Quality assurance is paramount in the production of fasteners. Reputable manufacturers implement rigorous testing protocols to ensure that their screws meet industry standards. This may involve tensile strength tests, corrosion resistance assessments, and dimensional checks to guarantee the reliability and durability of the product.

4. Innovation and Customization Leading manufacturers in the field continually explore innovative solutions to stay ahead of market demands. This can involve developing new screw designs, creating specialized coatings for enhanced performance, or even producing custom screws tailored to specific customer requirements. As industries evolve, so do the needs for fastening solutions, pushing manufacturers to innovate rapidly.

The Competitive Market

The market for M3 countersunk self-tapping screws is competitive, with numerous manufacturers vying for dominance. Companies differentiate themselves through product quality, pricing, customer service, and delivery capabilities. Many manufacturers also focus on building strong relationships with their clients, offering technical support and guidance to ensure the best solutions for various projects.

With the rise of e-commerce, many manufacturers have expanded their reach by selling directly to consumers and businesses online, providing greater accessibility to their products. This has led to an increase in supplier options for customers, promoting competitive pricing and innovation.

Conclusion

M3 countersunk self-tapping screws form an essential element in the toolkit of many industries, ranging from construction to electronics. Manufacturers play a vital role in this ecosystem, ensuring that each screw not only meets safety and quality standards but also addresses the evolving needs of their customers. The combination of proper material selection, precision engineering, stringent quality control, and proactive innovation ensures that M3 countersunk self-tapping screws remain reliable fasteners for a multitude of applications. As the market continues to grow, manufacturers who embrace change and prioritize customer needs are likely to thrive in the long run.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024