Feb . 10, 2025 22:11

Back to list

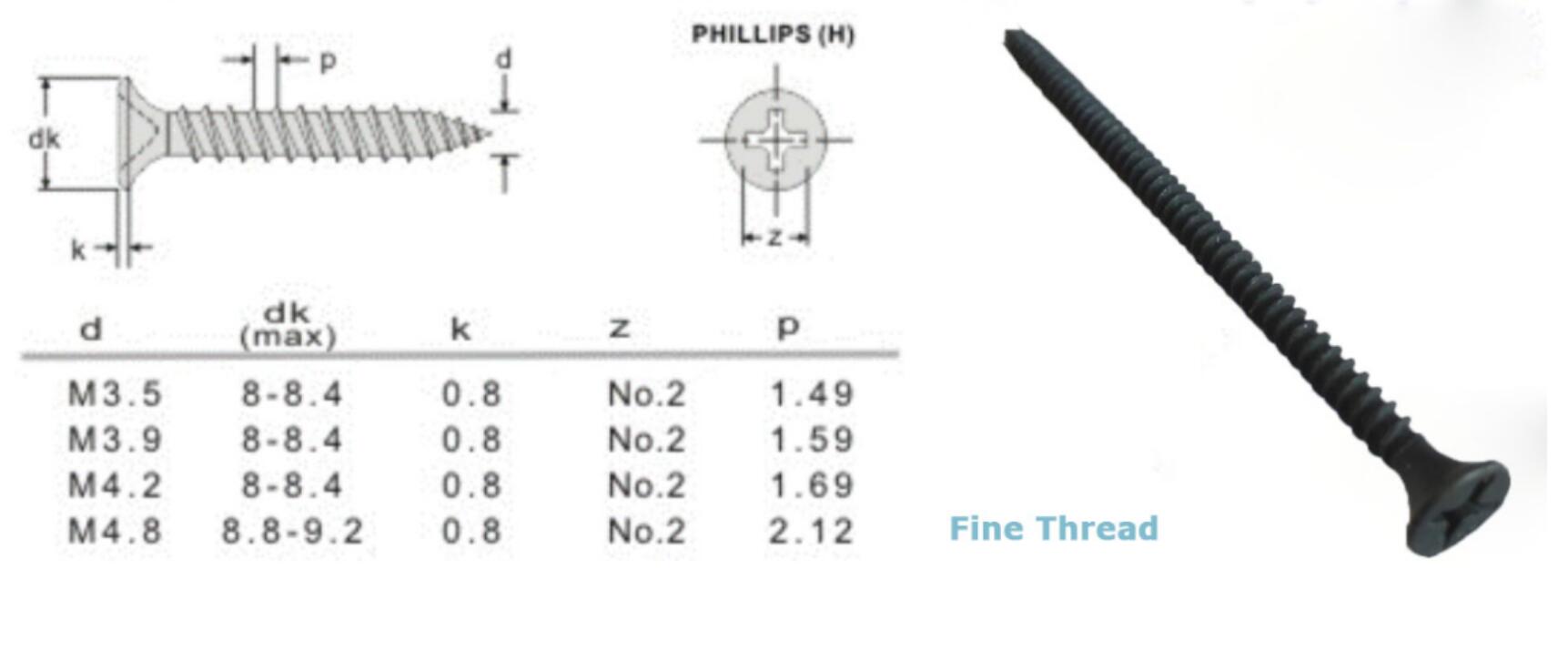

YZP CHIPBOARD SCREW

Navigating the vast world of fasteners is imperative for anyone involved in construction, manufacturing, or DIY projects. Among these, the M2x10 self-tapping screw stands out due to its precise engineering and versatility. This small but mighty component plays a crucial role in many industrial and personal applications.

User experience tells an equally compelling story. Consumers in forums and product review sites consistently praise the M2x10 for its ease of use and reliability. Novice DIY enthusiasts find them user-friendly due to their forgiving nature when it comes to alignment and pressure application. The sharp, precision-engineered tip ensures a smooth start with every application, minimizing the risk of splitting or damaging materials. Additionally, the quality control standards in manufacturing these screws are exceptionally high, ensuring that users receive a consistent product every time. From a trustworthiness perspective, many reputable manufacturers and suppliers offer these screws, adhering to international standards and certifications. Companies often provide detailed specifications and guidelines for use, which reflects transparency and commitment to customer satisfaction. Thorough testing and verification processes ascertain that every M2x10 self-tapping screw meets the required safety and performance standards. The continuous innovation surrounding self-tapping screws, including the M2x10, speaks to an industry committed to excellence. Advances in materials science and engineering have led to the development of variants with enhanced properties, such as increased heat resistance for industrial applications. In conclusion, whether you're an industrial engineer, a procurement manager, or a DIY hobbyist, the M2x10 self-tapping screw is a reliable choice that balances convenience, durability, and efficiency. Its role in modern construction and manufacturing is underscored by its ability to adapt to diverse needs while maintaining robust performance. As industries evolve, the demand for versatile and trustworthy fasteners like the M2x10 will only grow, making them a staple in every toolkit.

User experience tells an equally compelling story. Consumers in forums and product review sites consistently praise the M2x10 for its ease of use and reliability. Novice DIY enthusiasts find them user-friendly due to their forgiving nature when it comes to alignment and pressure application. The sharp, precision-engineered tip ensures a smooth start with every application, minimizing the risk of splitting or damaging materials. Additionally, the quality control standards in manufacturing these screws are exceptionally high, ensuring that users receive a consistent product every time. From a trustworthiness perspective, many reputable manufacturers and suppliers offer these screws, adhering to international standards and certifications. Companies often provide detailed specifications and guidelines for use, which reflects transparency and commitment to customer satisfaction. Thorough testing and verification processes ascertain that every M2x10 self-tapping screw meets the required safety and performance standards. The continuous innovation surrounding self-tapping screws, including the M2x10, speaks to an industry committed to excellence. Advances in materials science and engineering have led to the development of variants with enhanced properties, such as increased heat resistance for industrial applications. In conclusion, whether you're an industrial engineer, a procurement manager, or a DIY hobbyist, the M2x10 self-tapping screw is a reliable choice that balances convenience, durability, and efficiency. Its role in modern construction and manufacturing is underscored by its ability to adapt to diverse needs while maintaining robust performance. As industries evolve, the demand for versatile and trustworthy fasteners like the M2x10 will only grow, making them a staple in every toolkit.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News