Innovative ODM Design for Helical Spring Lock Washers with Enhanced Durability and Performance

Understanding ODM Helical Spring Lock Washers

In the world of mechanical engineering, the importance of fasteners cannot be overstated. Among the array of fasteners available, ODM helical spring lock washers play a critical role in ensuring the reliability and durability of bolted connections. This article will delve into the design, function, and applications of these specialized washers, highlighting their significance in various industries.

What is an ODM Helical Spring Lock Washer?

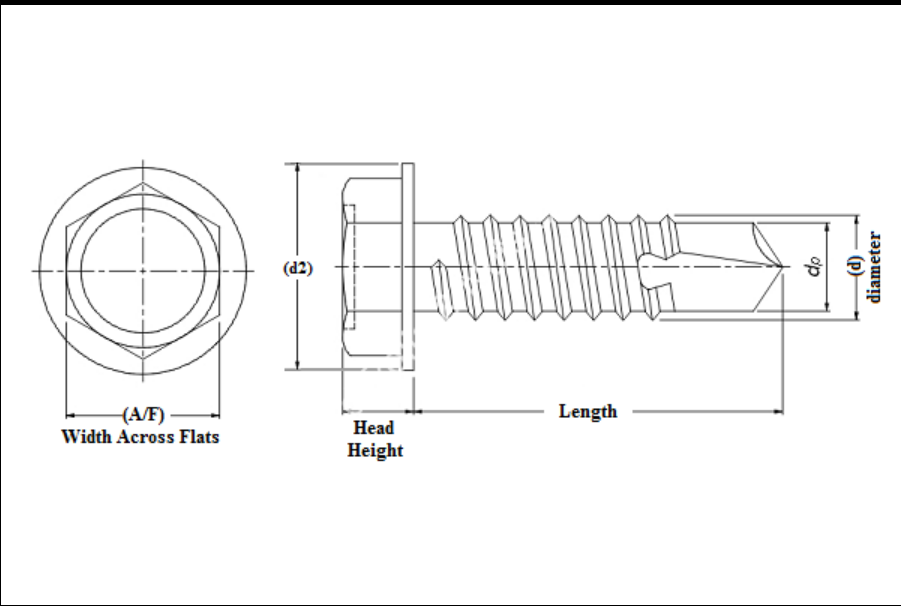

ODM helical spring lock washers are a type of disc spring washer designed to provide enhanced locking capabilities to fasteners. The term OD stands for outer diameter, referring to the size of the washer, while M denotes its metric specification. These washers are characterized by their helical shape, which allows them to distribute load more evenly and reduce the risk of loosening due to dynamic forces such as vibration or thermal expansion.

The design of helix-shaped washers features a slight twist that helps maintain tension on the bolt or screw it is paired with. When the fastener is tightened, the spring characteristics of the washer enable it to absorb shock and vibration, thereby preventing the fastener from becoming loose over time. This is particularly important in applications where equipment experiences constant motion or vibration, such as in automotive, aerospace, and heavy machinery sectors.

Key Advantages

1. Vibration Resistance One of the primary benefits of ODM helical spring lock washers is their ability to resist loosening under vibratory conditions. The unique design allows the washer to expand and contract with the fastener material, keeping consistent pressure on the connection.

2. Load Distribution The helical shape of the washer allows for better load distribution across the surface of the connection. This reduces the risk of stress concentration and damage to the components being joined.

odm helical spring lock washer

3. Durability Made from high-quality materials such as stainless steel or carbon steel, ODM helical spring lock washers are designed to withstand various environmental conditions, including moisture, heat, and corrosive elements.

4. Reusability Unlike some locking mechanisms that may become compromised after a single use, these washers can often be reused, provided they remain undamaged after installation, making them a cost-effective choice over time.

Applications

Thanks to their robust features, ODM helical spring lock washers are commonly used in various applications, including

- Automotive Industry In vehicles, these washers can be found in engine components, suspension systems, and bodywork where vibrations are common. - Aerospace The aerospace sector demands high reliability, and these washers play a vital role in ensuring that critical connections remain secure during flight. - Manufacturing Equipment Heavy machinery in factories relies on reliable fasteners to operate safely and efficiently, making these washers indispensable. - Electronics In the realm of electronics, where electronic circuit boards need secure connections without the risk of loosening, ODM helical spring lock washers provide an essential solution.

Conclusion

In summary, ODM helical spring lock washers are more than just simple fasteners; they are essential components that enhance the security and longevity of mechanical connections. Their unique design offers significant advantages in load distribution, vibration resistance, and overall durability. As industries continue to evolve, the demand for reliable fastening solutions will only grow, and ODM helical spring lock washers stand out as a critical innovation in this field. Whether in automotive, aerospace, or industrial applications, these washers provide the peace of mind that connections will remain intact under dynamic conditions, ensuring the safety and efficiency of machinery and equipment.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024