Innovative Machines for Self-Drilling Screw Applications in Construction and Manufacturing Industries

The Innovation and Importance of Self-Drilling Screw Machines in Modern Manufacturing

Self-drilling screws have revolutionized various sectors in manufacturing and construction, streamlining processes that once required multiple steps and specialized tools. With the integration of self-drilling screw machines, the fastening process has become simpler, faster, and more efficient. This article delves into the significance of self-drilling screw machines and their impact on modern production techniques.

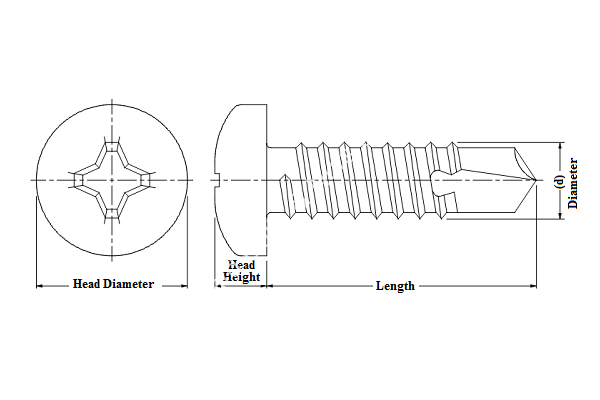

Self-drilling screws, also known as self-tapping screws, are specifically designed to eliminate the need for pre-drilling holes in the material to be secured. These screws have a drill-like point that allows them to create their own hole as they are driven into materials like metal, wood, or plastic. As a result, they facilitate a quicker assembly process, reducing labor costs and the time required to complete projects.

Self-drilling screw machines are essential in optimizing the performance of these innovative fasteners. These machines are engineered to automatically handle the insertion of screws into various materials with precision and speed. They typically operate using a combination of pneumatic pressure and electric power, allowing for consistent torque settings that enhance the stability of the fastened joint.

One of the standout features of self-drilling screw machines is their ability to operate within a wide range of parameters, making them suitable for different applications. From automotive manufacturing to construction projects, these machines are vital in industries where a secure and reliable fastening solution is paramount. In addition, the versatility of these machines allows manufacturers to switch between screw sizes and types quickly, enhancing their productivity and adaptability.

self drilling screw machine products

In the era of automation, self-drilling screw machines symbolize the integration of technology into traditional manufacturing processes. For example, many modern self-drilling screw machines come equipped with advanced sensors and software that monitor the entire fastening process, ensuring that screws are applied correctly without defects. This incorporation of technology reduces the chances of human error, leading to higher quality products and increased safety on the production floor.

Moreover, using self-drilling screws significantly reduces the environmental impact of manufacturing processes. Traditional methods often involve drilling holes and generating waste materials, which can be mitigated by using these efficient fasteners. With self-drilling screws, the reduction in waste not only supports sustainability efforts but also lowers material costs for manufacturers.

The demand for self-drilling screw machines is increasing, particularly as industries continue to prioritize efficiency and quality in their operations. As manufacturers strive to meet global production standards, investing in advanced screw fastening technology becomes essential. The ability to produce robust and durable products with less time and fewer resources aligns with the goals of modern-day manufacturing.

In conclusion, self-drilling screw machines are vital tools that enhance the efficiency of fastening processes across various industries. By eliminating the need for pre-drilling and ensuring consistent, high-quality results, these machines are transforming manufacturing practices. As we continue to innovate and embrace automation, the importance of self-drilling screw machines in achieving efficient and sustainable production will only grow. The future of manufacturing looks promising with these advanced technologies paving the way for new standards in productivity and quality.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024