Optimal Positioning of High-Quality Spring Washers for Enhanced Performance and Durability

The Importance of High-Quality Spring Washer Placement

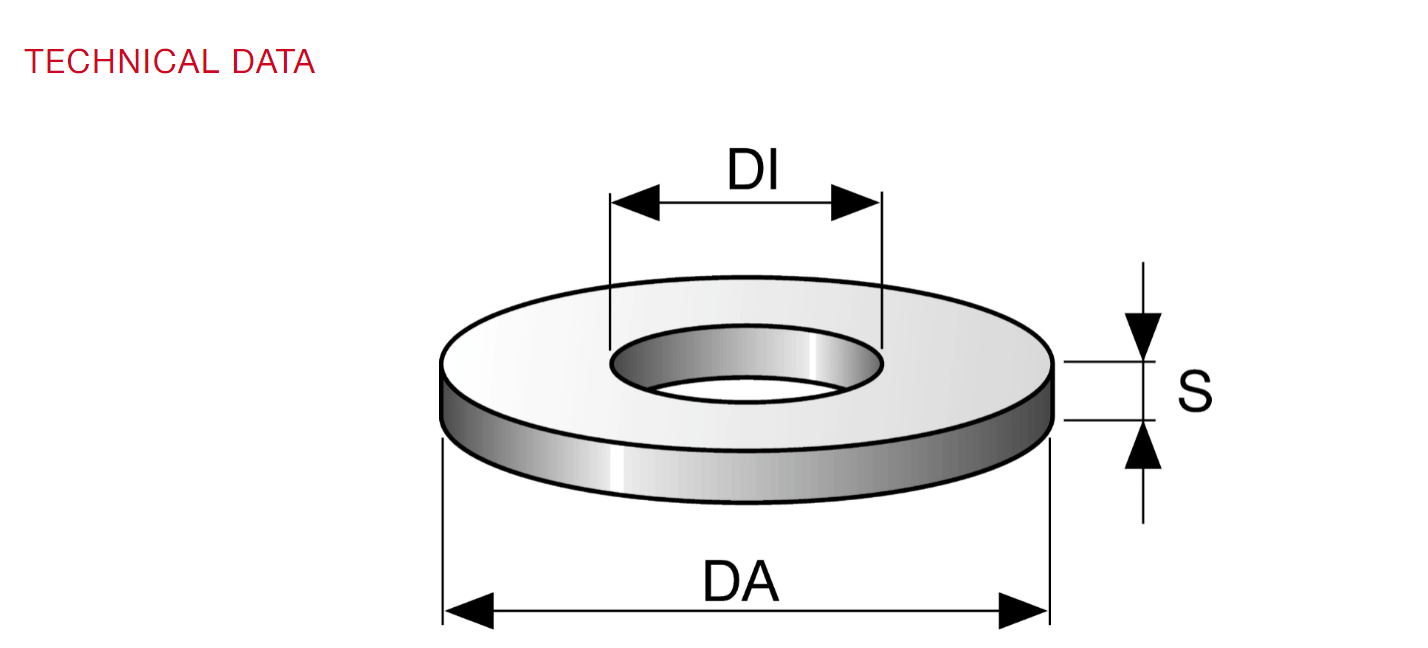

Spring washers are often overlooked components in mechanical assemblies, yet their role is crucial for ensuring the longevity and reliability of various applications. When discussing the placement of high-quality spring washers, it is essential to understand their functions and the best practices for their installation.

The Importance of High-Quality Spring Washer Placement

Proper placement of spring washers is critical to their effectiveness. When installing a spring washer, it should always be positioned with the curved side facing the component being secured. This orientation allows the washer to apply an effective preload to the bolt or nut, enhancing its clamping force. If installed incorrectly, the washer may not perform as intended, leading to premature failure of the joint.

high quality spring washer placement

Moreover, it is essential to ensure that the surface on which the washer sits is clean and free from debris. Contaminants can interfere with the washer's ability to grip the fastener securely, potentially resulting in loosening over time. Additionally, the selection of the correct size washer for the bolt or nut dimensions is crucial. A washer that is too small may not provide adequate support, while an oversized washer can lead to uneven load distribution.

Another best practice for spring washer placement involves following torque specifications during assembly. Over-tightening can deform the washer, negating its spring characteristics and leading to eventual failure. Conversely, under-tightening can fail to achieve the required preload. Utilizing torque wrenches to adhere to manufacturer recommendations is essential in this regard.

In conclusion, high-quality spring washer placement is vital for the reliability of mechanical systems. By selecting the right type of washer, ensuring proper orientation during installation, maintaining cleanliness, and adhering to torque specifications, engineers and technicians can significantly enhance the performance and durability of their assemblies. This attention to detail not only improves safety but also extends the life of the equipment, making it a worthwhile investment in any engineering project.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024