high quality nylon flat washer

The Importance of High-Quality Nylon Flat Washers

In various industries, the smallest components can have significant impacts on the performance and longevity of machinery and structures. One such component is the high-quality nylon flat washer. Though often overlooked, these washers play a crucial role in ensuring the integrity and reliability of mechanical assemblies.

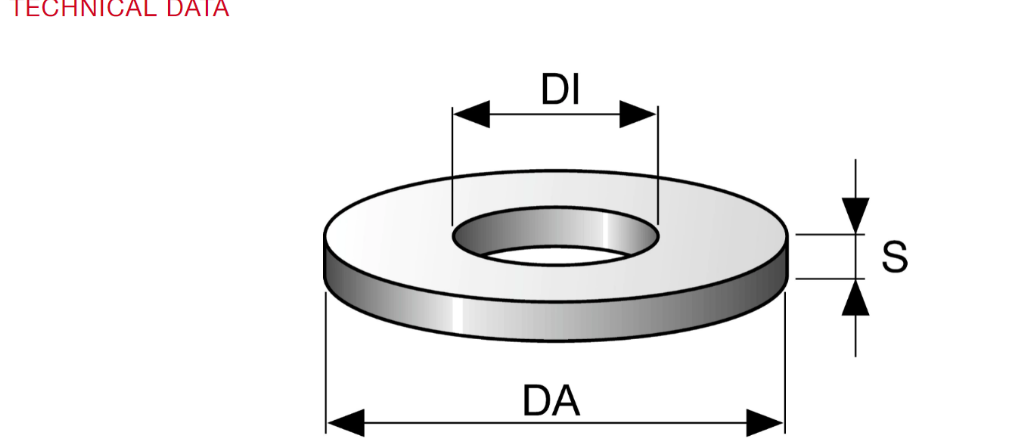

Nylon flat washers are circular discs made from durable nylon plastic, designed to be placed beneath nuts, bolts, and screws. Their primary purpose is to distribute the load of the fastener over a larger surface area, preventing damage to the material being fastened. However, the advantages of high-quality nylon washers extend far beyond load distribution.

Durability and Corrosion Resistance

One of the standout features of nylon flat washers is their excellent durability. Unlike metal washers, which may corrode in harsh environments, nylon is inherently resistant to moisture, chemicals, and UV radiation. This makes them particularly suitable for outdoor applications or situations where exposure to corrosive substances is a concern. High-quality nylon washers can withstand a wide range of temperatures and environmental conditions without losing their structural integrity.

Reduced Friction and Noise

Another significant benefit of using nylon flat washers is their ability to reduce friction and noise. When metal components are fastened together, they can create unwanted vibrations and sounds. Nylon's smooth surface minimizes friction between the washer and the fastener, leading to quieter operation and reduced wear on both parts. This is particularly important in applications such as automotive assemblies and machinery, where excessive noise and friction can lead to premature failure and increased maintenance costs.

high quality nylon flat washer

Electrical Insulation

Nylon is also an excellent electrical insulator, which adds another layer of functionality to nylon flat washers. This property is especially advantageous in electrical applications, where preventing short circuits and ensuring reliable connectivity is critical. By using high-quality nylon washers, engineers and designers can achieve improvements in safety and performance, particularly in sectors that require stringent compliance with electrical standards.

Versatility in Applications

The versatility of high-quality nylon flat washers is another reason for their popularity. They are used in a myriad of applications across various industries, including automotive, aerospace, electronics, and construction. From providing cushioning in sensitive electrical equipment to acting as spacers in mechanical assemblies, the uses of nylon flat washers are vast and varied.

Conclusion

In conclusion, high-quality nylon flat washers are crucial components in many mechanical and structural applications. Their durability, corrosion resistance, ability to reduce friction and noise, electrical insulation properties, and versatility make them an excellent choice for engineers and manufacturers alike. Investing in quality nylon washers can lead to improved performance, longer lifespan of components, and ultimately, greater satisfaction for end-users. As industries continue to evolve, the importance of reliable and efficient fastening solutions like high-quality nylon flat washers will only increase, solidifying their role in modern engineering and manufacturing.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024