Optimal Drill Sizes for 14 Self-Tapping Screws for High-Quality Results

The Importance of High-Quality Drill Sizes for 14 Self-Tapping Screws

When it comes to construction, woodworking, and various industrial applications, self-tapping screws are invaluable. Among the numerous variants available, the 14 self-tapping screw stands out for its versatility and strength. However, to achieve the best results with these screws, using the appropriate drill size is crucial. In this article, we will delve into why high-quality drill sizes matter when working with 14 self-tapping screws.

Understanding Self-Tapping Screws

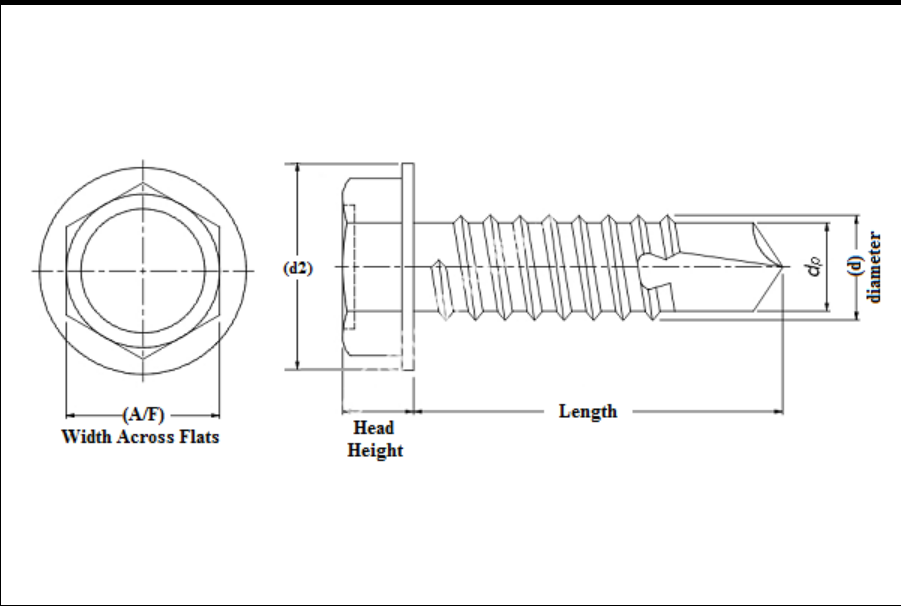

Self-tapping screws are designed to create their own holes as they are driven into the material. This feature makes them especially useful in situations where pilot holes are either impractical or impossible to pre-drill. The unique design of self-tapping screws often includes a sharp point and thread that allows them to penetrate different materials efficiently, including plastic, metal, and wood. The 14 designation indicates the size and thread count of the screw, which in turn dictates the suitable drill size for optimal performance.

The Role of Drill Size

Correct drill size is fundamental to ensuring the longevity and effectiveness of self-tapping screws. If the drill hole is too small, the screw may not fit correctly and can cause damage to the material, leading to decreased structural integrity. On the other hand, if the hole is too large, the screw may not hold securely, resulting in instability and eventual failure. Therefore, selecting the right drill size is essential.

Using a high-quality drill bit is equally important as the material from which it is made can affect the drill’s performance. High-quality drill bits typically have better cutting power, durability, and heat resistance, which reduces the risk of overheating and breakage.

Factors Influencing Drill Size Selection

high quality drill size for 14 self tapping screw

Several factors can influence the choice of drill size for 14 self-tapping screws, including material type, screw diameter, and threading characteristics.

1. Material Type Different materials have different densities and hardness. For instance, softwood requires a different approach than steel. For self-tapping screws, a smaller drill bit may be suitable for softer materials, while harder materials might necessitate a slightly larger drill to accommodate the screw's threads.

2. Screw Diameter The diameter of the self-tapping screw is a critical determinant in selecting the drill bit size. Generally, the drill bit diameter should match the minor diameter of the screw threads for effective engagement. This allows the threads to grip adequately in the material without risking damage.

3. Threading Characteristics The type of threading can also impact drill size. Some self-tapping screws have finer threads, while others are coarser. Coarser threads can tap into materials more aggressively and may require a larger drill size to accommodate the wider spiral of the thread.

Conclusion

Using the correct drill size is essential for maximizing the benefits of 14 self-tapping screws. Opting for high-quality drill bits not only helps in achieving appropriate hole sizes but also minimizes wear and tear during use. Therefore, investing in quality tools is a must for both professionals and DIY enthusiasts.

Whether you’re constructing furniture, assembling machinery, or engaging in home improvement projects, ensuring that you use the correct drill size can save time, reduce waste, and yield stronger, more durable installations. Understanding the interaction between drill sizes, self-tapping screws, and the materials you are working with will lead to higher-quality results and enhance the overall efficiency of your work.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024