Jun . 26, 2024 01:59

Back to list

Highly Rated M8 Self-Tapping Screw Top Choice for Efficient Fastening

Understanding the Significance of Famous M8 Self-Tapping Screws in Modern Construction and Manufacturing

In the world of fasteners, the M8 self-tapping screw stands out as a prominent player, particularly in the context of efficient construction and manufacturing processes. This type of screw, known for its versatility and ease of use, has gained significant fame due to its ability to tap its own threads in a mating part, eliminating the need for pre-threaded holes.

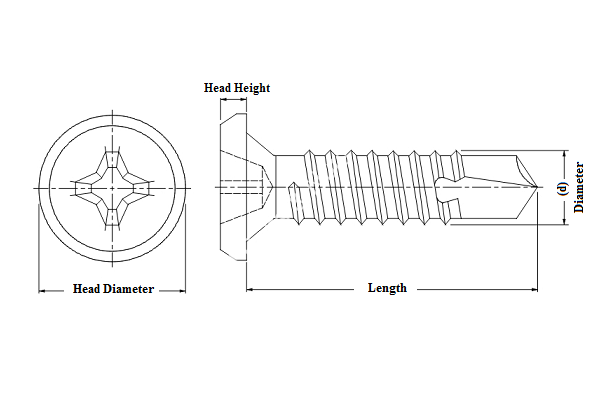

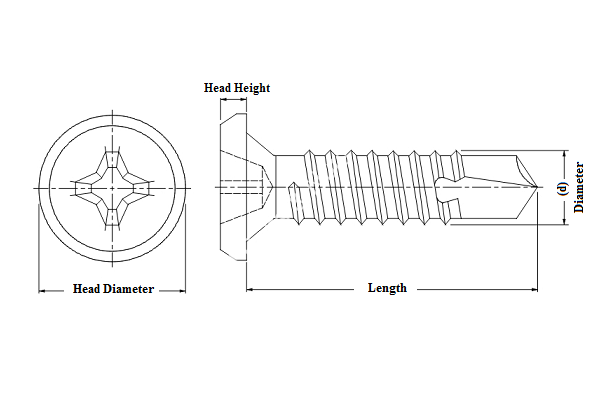

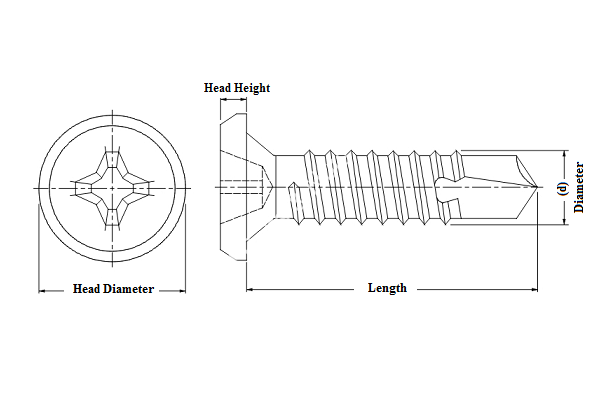

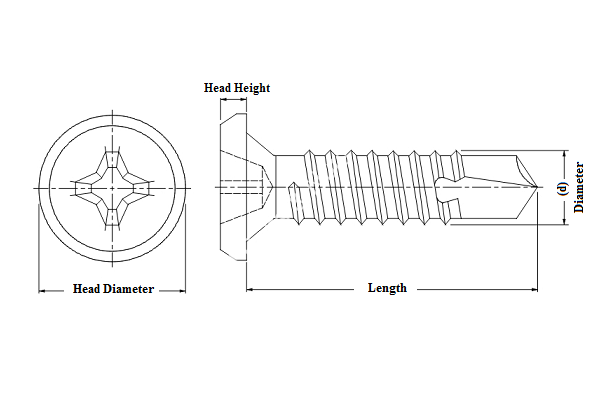

The 'M8' in the name refers to the metric system's designation for the screw's major diameter, which is 8 millimeters. These screws are designed with a sharp thread at the tip, allowing them to cut into a variety of materials such as metal, plastic, or wood, creating a thread that they can securely anchor into. This unique feature saves time and effort, as it negates the preparatory step of threading the material beforehand.

Famous M8 self-tapping screws find extensive application in various industries. In construction, they are often used in roofing, plumbing, and electrical installations due to their strength and ability to hold tightly in place. Their self-tapping nature also ensures a tighter fit, reducing the risk of loosening over time. In manufacturing, they are integral in assembling machinery, furniture, and automotive parts, where quick and secure fastening is crucial.

One key advantage of M8 self-tapping screws is their adaptability. They can be used in materials ranging from soft woods to thick metals, making them a go-to solution for engineers and builders. Furthermore, their self-tapping capability minimizes the risk of stripped threads, a common issue with conventional screws Furthermore, their self-tapping capability minimizes the risk of stripped threads, a common issue with conventional screws Furthermore, their self-tapping capability minimizes the risk of stripped threads, a common issue with conventional screws Furthermore, their self-tapping capability minimizes the risk of stripped threads, a common issue with conventional screws

Furthermore, their self-tapping capability minimizes the risk of stripped threads, a common issue with conventional screws Furthermore, their self-tapping capability minimizes the risk of stripped threads, a common issue with conventional screws famous m8 self tapping screw.

The fame of M8 self-tapping screws is also attributed to their durability. Made from high-quality materials like steel or stainless steel, they resist corrosion and wear, ensuring a long service life. Additionally, their standardized size allows for easy sourcing and replacement, simplifying inventory management.

However, proper usage is paramount. The torque applied during installation should be controlled to prevent damage to the tapped thread or the screw itself. It is also essential to select the right type of self-tapping screw for the specific application, considering factors like the thickness of the material, load-bearing requirements, and environmental conditions.

In conclusion, the famous M8 self-tapping screw is more than just a simple fastener; it is a testament to the power of innovation in streamlining processes and enhancing efficiency. Its popularity lies in its ability to simplify tasks, save time, and provide reliable performance across a wide range of industries. As technology continues to evolve, the M8 self-tapping screw remains an indispensable tool in modern construction and manufacturing practices.

famous m8 self tapping screw.

The fame of M8 self-tapping screws is also attributed to their durability. Made from high-quality materials like steel or stainless steel, they resist corrosion and wear, ensuring a long service life. Additionally, their standardized size allows for easy sourcing and replacement, simplifying inventory management.

However, proper usage is paramount. The torque applied during installation should be controlled to prevent damage to the tapped thread or the screw itself. It is also essential to select the right type of self-tapping screw for the specific application, considering factors like the thickness of the material, load-bearing requirements, and environmental conditions.

In conclusion, the famous M8 self-tapping screw is more than just a simple fastener; it is a testament to the power of innovation in streamlining processes and enhancing efficiency. Its popularity lies in its ability to simplify tasks, save time, and provide reliable performance across a wide range of industries. As technology continues to evolve, the M8 self-tapping screw remains an indispensable tool in modern construction and manufacturing practices.

Furthermore, their self-tapping capability minimizes the risk of stripped threads, a common issue with conventional screws Furthermore, their self-tapping capability minimizes the risk of stripped threads, a common issue with conventional screws

Furthermore, their self-tapping capability minimizes the risk of stripped threads, a common issue with conventional screws Furthermore, their self-tapping capability minimizes the risk of stripped threads, a common issue with conventional screws famous m8 self tapping screw.

The fame of M8 self-tapping screws is also attributed to their durability. Made from high-quality materials like steel or stainless steel, they resist corrosion and wear, ensuring a long service life. Additionally, their standardized size allows for easy sourcing and replacement, simplifying inventory management.

However, proper usage is paramount. The torque applied during installation should be controlled to prevent damage to the tapped thread or the screw itself. It is also essential to select the right type of self-tapping screw for the specific application, considering factors like the thickness of the material, load-bearing requirements, and environmental conditions.

In conclusion, the famous M8 self-tapping screw is more than just a simple fastener; it is a testament to the power of innovation in streamlining processes and enhancing efficiency. Its popularity lies in its ability to simplify tasks, save time, and provide reliable performance across a wide range of industries. As technology continues to evolve, the M8 self-tapping screw remains an indispensable tool in modern construction and manufacturing practices.

famous m8 self tapping screw.

The fame of M8 self-tapping screws is also attributed to their durability. Made from high-quality materials like steel or stainless steel, they resist corrosion and wear, ensuring a long service life. Additionally, their standardized size allows for easy sourcing and replacement, simplifying inventory management.

However, proper usage is paramount. The torque applied during installation should be controlled to prevent damage to the tapped thread or the screw itself. It is also essential to select the right type of self-tapping screw for the specific application, considering factors like the thickness of the material, load-bearing requirements, and environmental conditions.

In conclusion, the famous M8 self-tapping screw is more than just a simple fastener; it is a testament to the power of innovation in streamlining processes and enhancing efficiency. Its popularity lies in its ability to simplify tasks, save time, and provide reliable performance across a wide range of industries. As technology continues to evolve, the M8 self-tapping screw remains an indispensable tool in modern construction and manufacturing practices. Next:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News