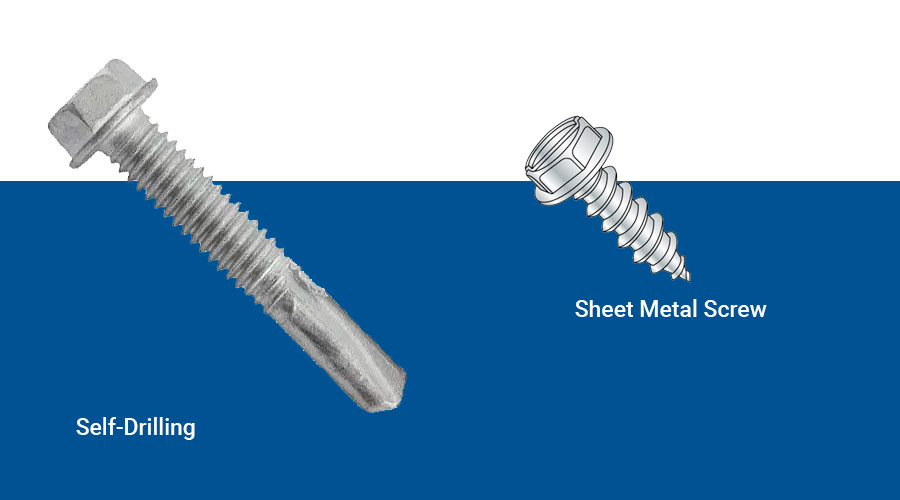

Self-drilling screws, like the name suggests, are screws that drill their own holes, the installer doesn’t need to drill a pilot hole. Self-drilling screws are sometimes confused with self-tapping screws. A self-tapping screw is a sheet metal screw. The difference is that self-tapping screws are installed into pre-punched or pre-drilled holes.

Self-drilling screws should be installed using a variable speed screw gun, (not an impact driver) like the DeWALT DCF622M2 RPMs are critical when driving self-drilling screws. High RPM’S can cause point burnout.

When driving self-drilling screws, do not use too much pressure. Using too much pressure will create too much heat on the screw point and can also cause point burnout. Use just enough pressure to keep the screw steady, push the trigger to the desired rpm, and then push the screw into the material.

A Self-Drilling Screw Must Be Harder Than the Material It’s Going Into.

| Material | C1018-C1022 /410SS |

| Heat Treated | Case Harden |

| Case Hardness | 52-58 Rockwell C |

| Case Depth | #8, #10, #12 Dia. screws = .004″-.009″ |

| Core Hardness | Carbon Steel: 32-40 Rockwell C 410 Stainless: 42-48 Rockwell C |

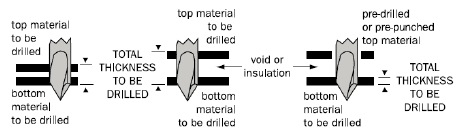

When selecting our screw size and length, remember to take into consideration of the total thickness of the material, including the gap between the two pieces being joined. The drill flute length is critical to material thickness. It’s important that the point length is long enough before that thread starts to engage. Otherwise, you risk the point of the screw burning out.

The last item to remember when purchasing self-drilling screws for a project is to order screws that have been performance tested by the International Code Council. The ICC

is the leading global source of model codes and standards and building safety solutions and includes product evaluation. The standards of the ICC are used to ensure products have been thoroughly tested for quality and the manufacturer has passed all quality tests.