Hex Flange Head Self Drilling Screws - Quality Fasteners for Your Projects

Understanding Hex Flange Head Self-Drilling Screws A Key Component for Modern Construction

Understanding Hex Flange Head Self-Drilling Screws A Key Component for Modern Construction

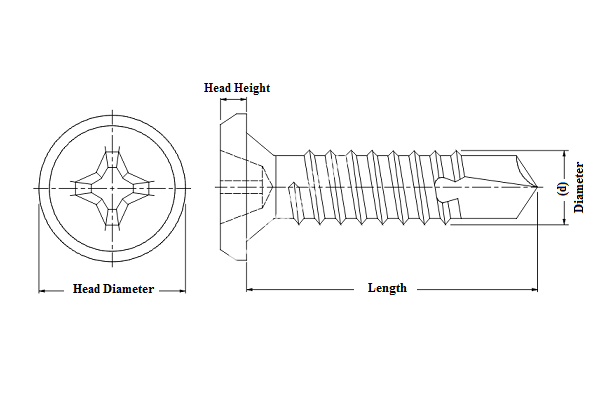

Hex flange head self-drilling screws are designed with a hexagonal head, which allows for easy driving with socket wrenches or power drills. The flange beneath the head provides a larger bearing surface, distributing the load and reducing the risk of damage to the material being fastened. One of the key attributes of these screws is their ability to drill their own pilot hole, which eliminates the need for pre-drilling and significantly speeds up the installation process. This self-drilling feature is particularly advantageous in metal-to-metal and metal-to-wood applications, as it ensures a tight, secure fit without compromising the structural integrity.

hex flange head self drilling screw company

One of the primary applications for hex flange head self-drilling screws is in the construction of metal buildings, where they are used to fasten metal panels, framing, and other components. Their corrosion-resistant coatings, such as zinc plating or epoxy finishes, make them ideal for outdoor and harsh environments, ensuring longevity and reliability in various weather conditions. Additionally, these screws are commonly used in the automotive industry, HVAC systems, and for installing roofing and siding materials.

The manufacturing quality of the screws is paramount. Reputable companies that specialize in producing hex flange head self-drilling screws focus on stringent quality control processes, ensuring that each screw meets industry standards. This level of quality assurance enhances the structural integrity of the projects where these screws are utilized. Moreover, many manufacturers offer customization options, allowing clients to select specific materials, coatings, and sizes to meet their project requirements.

In conclusion, hex flange head self-drilling screws are a vital component in modern construction, offering versatility, strength, and efficiency. Their self-drilling capability reduces labor time and simplifies installation, making them a preferred choice for many construction professionals. As the demand for durable and reliable fastening solutions continues to grow, companies focused on this niche market are likely to see increased opportunities for growth and innovation. Understanding the benefits and applications of these screws can lead to better choices in materials, ultimately enhancing the quality of construction projects. Embracing such innovations reflects a commitment to quality and efficiency in an ever-evolving industry.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024