Guidelines for Creating Pilot Holes for Efficient Self-Tapping Screw Installation Techniques

Understanding Wholesale Pilot Holes for Self-Tapping Screws

In the world of construction and manufacturing, the significance of selecting the right components for a project cannot be overstated. One such crucial element is the pilot hole, especially when it comes to self-tapping screws. This article will explore the concept of wholesale pilot holes for self-tapping screws, discussing their importance, applications, and best practices.

What is a Pilot Hole?

A pilot hole is a small hole drilled into a material to guide the insertion of a screw. For self-tapping screws, which are designed to create their own threads as they are driven into a material, pilot holes can enhance performance and ensure a secure fit. Pilot holes are particularly advantageous when working with harder materials, such as metal or dense wood, where the screw might struggle to penetrate without aid.

The Importance of Pilot Holes

1. Material Integrity Drilling a pilot hole can prevent splitting or cracking in materials, particularly in wood. When screws are driven directly into the material without a pilot hole, the pressure can cause the material to break. A properly sized pilot hole minimizes this risk.

2. Ease of Insertion Self-tapping screws are easier to install when pilot holes are used. The pilot hole reduces resistance, allowing the screw to be inserted more easily and quickly, which is particularly beneficial in large-scale production environments.

3. Accuracy Creating pilot holes ensures that screws are driven straight and true. Misalignment can lead to weak joints and compromised structural integrity, making pilot holes a crucial step in ensuring accuracy.

4. Thread Engagement For self-tapping screws, the pilot hole allows for optimal thread engagement. It ensures that the screw's threads can properly bite into the material, creating a secure fastening without excessive force.

Wholesale Considerations

wholesale pilot hole for self tapping screw

In bulk manufacturing or large-scale construction projects, sourcing pilot holes can become a crucial aspect of efficiency and cost-effectiveness. Wholesale pilot holes refer to the practice of drilling pilot holes in materials before they reach the construction site or assembly line. This can be particularly beneficial for manufacturers and suppliers looking to streamline their processes.

1. Cost Efficiency By preparing materials with pilot holes wholesale, manufacturers can save time and labor costs during assembly. This not only reduces the total time needed for construction but can also lower the overall expense of a project.

2. Quality Control When pilot holes are drilled in a controlled environment, it allows for better quality assurance. Uniformity in the size and depth of pilot holes can result in more reliable applications of self-tapping screws.

3. Customization Wholesale services can offer customized pilot hole solutions. Depending on the specific requirements of a project—such as the type of material, screw size, and depth needed—wholesale providers can tailor the pilot hole specifications accordingly.

Best Practices for Pilot Holes

When creating pilot holes for self-tapping screws, certain best practices should be observed

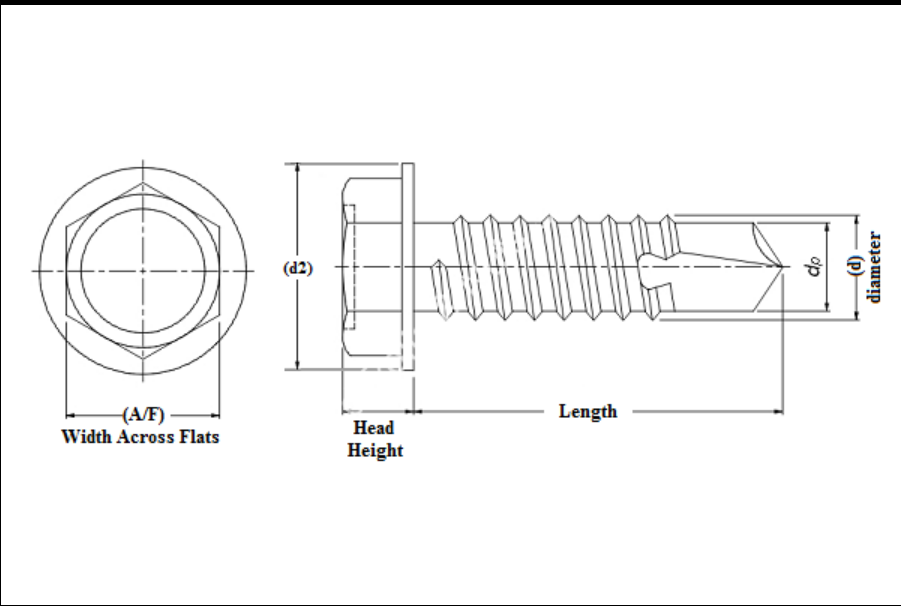

1. Size Matters The diameter of the pilot hole should be slightly smaller than the screw’s minor diameter (the diameter of the screw shaft without counting the threads). For typical self-tapping screws, a pilot hole that is approximately 60-80% of the screw's diameter is often effective.

2. Depth Ensure that the depth of the pilot hole matches the length of the screw being used. A deeper pilot hole allows for a secure fit without impeding the screw's capabilities.

3. Material Consideration Different materials require different approaches. Softer materials may not need as wide or deep of a pilot hole, while harder materials will benefit from a more precisely sized pilot hole.

In conclusion, the creation of wholesale pilot holes for self-tapping screws represents an intersection of efficiency and precision in construction and manufacturing. By understanding the critical role of pilot holes in securing materials and ensuring accuracy, professionals can optimize their processes, reduce costs, and improve the overall quality of their projects. As industries continue to evolve, so too will the techniques and technologies that enhance the effectiveness of fasteners like self-tapping screws.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024