Jan . 14, 2025 12:35

Back to list

galvanized chipboard screw

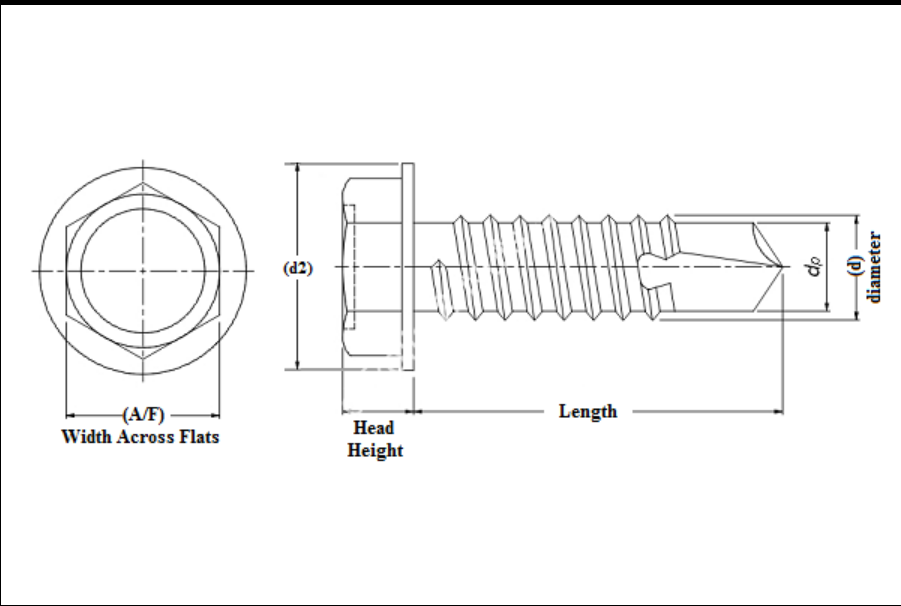

Galvanized chipboard screws are an indispensable component in the realm of construction and DIY projects. Boasting a robust zinc coating, these screws offer exceptional resistance to rust and corrosion, making them a preferred choice for both indoor and outdoor applications. Their unique construction is designed for securing chipboard, a type of engineered wood product made from woodchips and resin, used widely in the furniture and flooring industries.

From a technical standpoint, another key advantage is the ease with which these screws can be driven. Thanks to their sharp tip and deep thread design, they require less torque to penetrate chipboard. This efficiency not only speeds up the assembly process but also reduces strain on power tools, effectively lowering wear and tear on equipment. Given their significant strengths, galvanized chipboard screws are a favored solution among experts aiming to achieve high-quality, durable construction results. They embody a blend of expertise and innovation that meets the rigorous demands of modern construction projects. Their reliable performance fosters trust among professionals who depend on these fasteners for their day-to-day operations. The authoritative voice in the industry, Fastener World Magazine, highlights in their annual report that galvanized screws, in particular, continue to rise in popularity due to their versatility and unmatched resistance to environmental wear. Surveys reveal that over 80% of builders and contractors prefer using these types of screws over non-coated variants, citing their positive impact on project longevity and customer satisfaction. For anyone embarking on a project involving chipboard or similar materials, investing in galvanized chipboard screws is a decision backed by industry leaders and time-tested success. Whether you are an experienced builder or a DIY enthusiast, these screws offer a combination of dependability and performance that you can trust to deliver professional-grade results.

From a technical standpoint, another key advantage is the ease with which these screws can be driven. Thanks to their sharp tip and deep thread design, they require less torque to penetrate chipboard. This efficiency not only speeds up the assembly process but also reduces strain on power tools, effectively lowering wear and tear on equipment. Given their significant strengths, galvanized chipboard screws are a favored solution among experts aiming to achieve high-quality, durable construction results. They embody a blend of expertise and innovation that meets the rigorous demands of modern construction projects. Their reliable performance fosters trust among professionals who depend on these fasteners for their day-to-day operations. The authoritative voice in the industry, Fastener World Magazine, highlights in their annual report that galvanized screws, in particular, continue to rise in popularity due to their versatility and unmatched resistance to environmental wear. Surveys reveal that over 80% of builders and contractors prefer using these types of screws over non-coated variants, citing their positive impact on project longevity and customer satisfaction. For anyone embarking on a project involving chipboard or similar materials, investing in galvanized chipboard screws is a decision backed by industry leaders and time-tested success. Whether you are an experienced builder or a DIY enthusiast, these screws offer a combination of dependability and performance that you can trust to deliver professional-grade results.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News