Feb . 10, 2025 12:38

Back to list

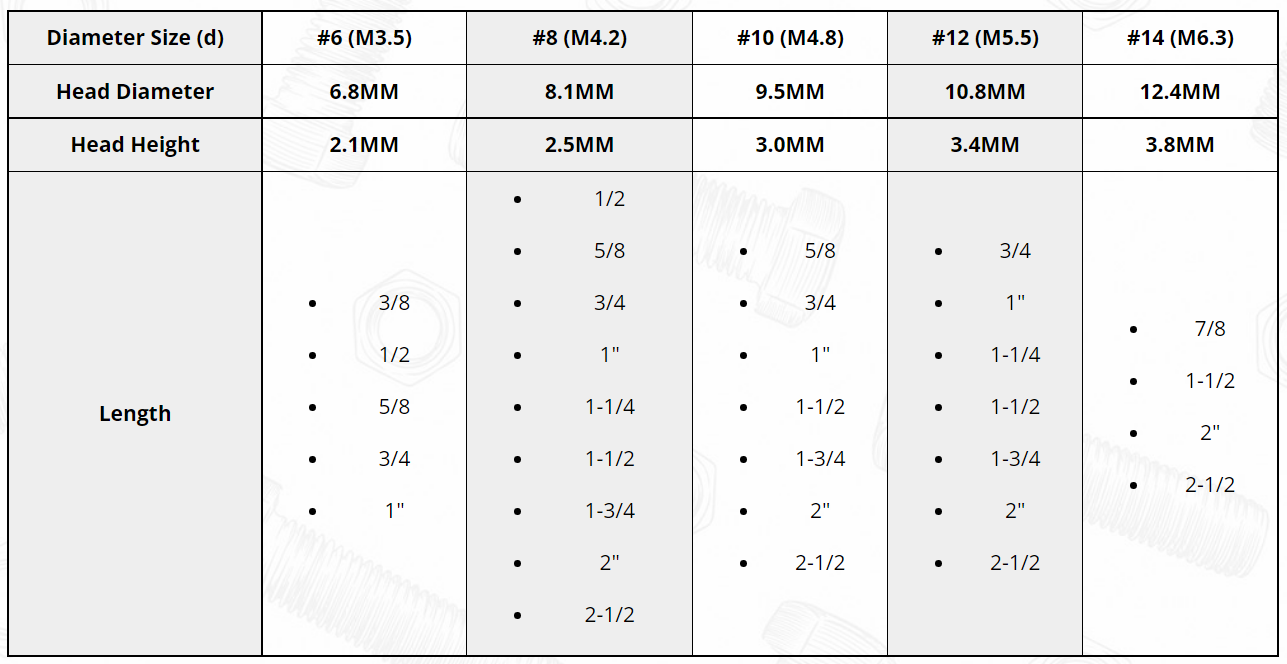

YZP CHIPBOARD SCREW

Flush self-tapping screws have evolved as a necessary component across various industries, championed for their unique design and exceptional functionality. These screws are engineered to cut their threads as they penetrate materials, offering unparalleled convenience and efficiency in numerous applications.

While flush self-tapping screws offer remarkable convenience, there are instances where pre-drilling might still be beneficial. For particularly tough materials or when working near the edge of the material, pre-drilling can prevent cracking or splitting, safeguarding the final product's quality. The authority of flush self-tapping screws is reinforced by their adherence to rigorous industry standards that dictate everything from dimensional accuracy to performance metrics. These standards ensure that every batch of screws delivers consistent quality, providing end users with the confidence that their projects will stand the test of time. Reputable manufacturers also conduct extensive testing on their products to certify that they meet these stringent requirements, further bolstering their reliability and reputation. Trustworthiness in purchasing flush self-tapping screws can often be determined by the manufacturer and supplier. Engaging with established brands that have a proven track record for quality can mitigate the risk of subpar performance. Reading reviews, consulting with industry peers, and examining product certifications can also provide valuable insight into the screw's quality and the supplier's credibility. Innovations in flush self-tapping screw technology continue to drive advancements in various fields. New coatings and materials are being developed to enhance screw performance in extreme temperatures or under high stress. As industries evolve, the demand for screws that can not only meet but exceed current requirements will spur further innovation and refinement. In summary, flush self-tapping screws are an engineered triumph, combining practicality with precision. Whether in the hands of a seasoned professional or an ambitious DIY enthusiast, these screws offer ease of use, reliability, and excellent results. Through mindful selection based on material, environment, and application, these screws provide durable and aesthetically pleasing solutions across a spectrum of industrial and personal projects.

While flush self-tapping screws offer remarkable convenience, there are instances where pre-drilling might still be beneficial. For particularly tough materials or when working near the edge of the material, pre-drilling can prevent cracking or splitting, safeguarding the final product's quality. The authority of flush self-tapping screws is reinforced by their adherence to rigorous industry standards that dictate everything from dimensional accuracy to performance metrics. These standards ensure that every batch of screws delivers consistent quality, providing end users with the confidence that their projects will stand the test of time. Reputable manufacturers also conduct extensive testing on their products to certify that they meet these stringent requirements, further bolstering their reliability and reputation. Trustworthiness in purchasing flush self-tapping screws can often be determined by the manufacturer and supplier. Engaging with established brands that have a proven track record for quality can mitigate the risk of subpar performance. Reading reviews, consulting with industry peers, and examining product certifications can also provide valuable insight into the screw's quality and the supplier's credibility. Innovations in flush self-tapping screw technology continue to drive advancements in various fields. New coatings and materials are being developed to enhance screw performance in extreme temperatures or under high stress. As industries evolve, the demand for screws that can not only meet but exceed current requirements will spur further innovation and refinement. In summary, flush self-tapping screws are an engineered triumph, combining practicality with precision. Whether in the hands of a seasoned professional or an ambitious DIY enthusiast, these screws offer ease of use, reliability, and excellent results. Through mindful selection based on material, environment, and application, these screws provide durable and aesthetically pleasing solutions across a spectrum of industrial and personal projects.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News