flat washer measurements factories

Understanding Flat Washer Measurements in Factories

Flat washers are essential components in various mechanical assemblies and applications. Often underestimated, these small, circular pieces play a critical role in distributing loads, reducing friction, and preventing damage to assemblies. In factories, understanding flat washer measurements is crucial to ensuring proper fit and function within systems. This article delves into the intricacies of flat washer measurements, their importance, and considerations for manufacturers.

What is a Flat Washer?

A flat washer is a thin plate with a hole in the center, commonly used to improve the load distribution of a threaded fastener, such as a bolt or screw. They come in various materials, including metal, plastic, and rubber, each serving different applications based on the material properties required, such as corrosion resistance, flexibility, or insulation.

Importance of Accurate Measurements

The proper measurement of flat washers is vital for a variety of reasons

1. Load Distribution When a washer is properly sized for the fastener it accompanies, it distributes the load evenly across the surface. This helps prevent deformation of the materials being joined and maintains the integrity of the assembly.

2. Preventing Damage An undersized washer can lead to material failure under stress, while an oversized washer might not provide adequate grip or could interfere with adjacent components. Accurate measurements help prevent these issues and prolong the life of both the fastener and the materials being fastened.

3. Compatibility Different applications require specific washer dimensions. The diameter of the washer, thickness, and inner hole size need to match the corresponding fasteners and materials. This compatibility is crucial in assembly lines, where multiple components are often handled at once.

4. Standardization Many industries adhere to standard specifications for washer measurements such as those set by the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO). Understanding these standards helps manufacturers produce compatible products and maintain quality across different batches.

Key Measurements for Flat Washers

flat washer measurements factories

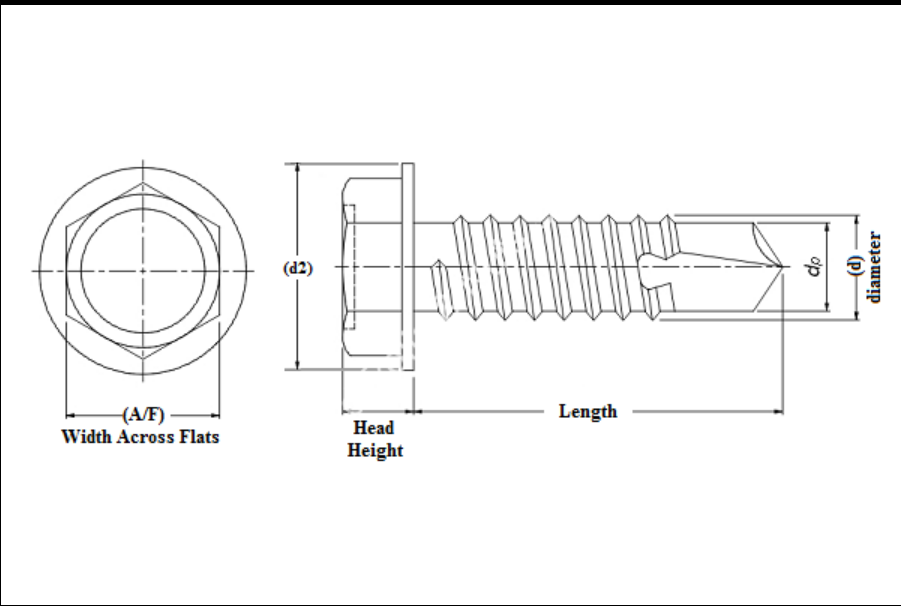

When measuring flat washers, there are several critical dimensions to consider

1. Outer Diameter (OD) This is the total diameter of the washer and is a crucial measurement for load distribution. The outer surface should be large enough to effectively distribute pressure.

2. Inner Diameter (ID) The hole in the center must match the size of the fastener that will pass through it. A close fit is necessary to prevent movement that could lead to loosening over time.

3. Thickness The thickness is another important measurement that determines the washer's strength and its ability to withstand shear forces without deforming.

4. Material Specifications Different applications may require specific materials based on environmental factors. For instance, stainless steel washers are preferred in marine applications due to their resistance to corrosion, while nylon washers might be chosen for electrical applications due to their insulating properties.

Quality Control in Manufacturing

In factories, ensuring the accuracy of flat washer measurements is paramount. Quality control processes should be in place to verify dimensions throughout the manufacturing process. This often involves

- Calibrating Measurement Tools Using calibrated tools to ensure that measurements are precise. - Batch Testing Conducting random sampling from production batches to check for conformity to specifications. - Documentation Keeping detailed records of measurements and quality control results to ensure traceability and consistency in production.

Conclusion

Flat washers may seem like trivial components in the grand scheme of engineering, yet their proper measurement and use are pivotal to the success of any mechanical assembly. Factories that focus on accurate measurements and quality control practices will not only produce reliable products but will also enhance overall operational efficiency. As technology advances, the methods for producing and measuring flat washers continue to evolve, but the fundamental principles of ensuring compatibility, load distribution, and durability remain timeless. Ultimately, understanding flat washer measurements is not just a matter of precision; it is a cornerstone of successful manufacturing practices.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024