Jan . 26, 2025 00:44

Back to list

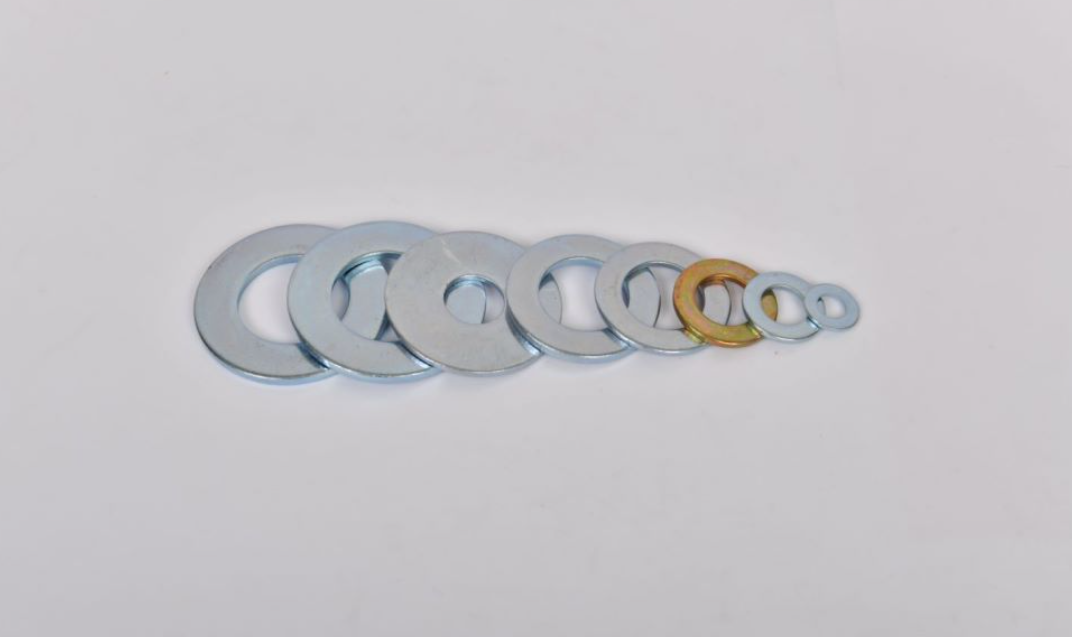

FLAT WASHER

M6 flat washers are essential components in the world of fasteners, offering a reliable solution for various construction and mechanical applications. A deep understanding of their function, material, and correct usage can significantly impact the performance and longevity of your projects. This expertise-driven guide will shed light on the critical aspects of M6 flat washers, ensuring you make informed decisions backed by authority and trust.

Installation is equally crucial. Excessive torque during assembly can deform or crack a standard M6 washer, diminishing its functionality. Utilizing a torque wrench calibrated to the manufacturer's specifications can prevent over-tightening, maintaining the integrity of the washer and the entire assembly. Furthermore, combining flat washers with lock washers can enhance grip and reduce the likelihood of loosening under dynamic loads. The application spectrum for M6 flat washers extends across diverse industries. In the automotive sector, they ensure the secure attachment of components subject to constant vibration. In construction, they safeguard materials from being damaged by fasteners. Their use extends to furniture assembly, aerospace applications, and even in the creation of intricate electronics, showcasing their versatility and indispensable nature. Elevating your projects with the right M6 flat washers not only enhances structural durability but also reflects a commitment to quality and precision. When armed with the knowledge of material benefits, size compatibility, and optimal usage techniques, you establish a foundation of trust and authority in choosing the correct components for robust results. For professionals seeking to uphold their reputation and meet industry standards, relying on reputable suppliers with an established track record is paramount. Verified manufacturers offering detailed product specifications, rigorous testing standards, and compliance with international regulations ensure you invest in washers that meet or exceed expectations. Choosing M6 flat washers starts as a simple selection but evolves into a decision impacting the overall success of your engineering endeavors. With experience, expertise, authority, and trust as your guiding principles, you can navigate this choice with confidence, resulting in assemblies that stand the test of time and exemplify excellence.

Installation is equally crucial. Excessive torque during assembly can deform or crack a standard M6 washer, diminishing its functionality. Utilizing a torque wrench calibrated to the manufacturer's specifications can prevent over-tightening, maintaining the integrity of the washer and the entire assembly. Furthermore, combining flat washers with lock washers can enhance grip and reduce the likelihood of loosening under dynamic loads. The application spectrum for M6 flat washers extends across diverse industries. In the automotive sector, they ensure the secure attachment of components subject to constant vibration. In construction, they safeguard materials from being damaged by fasteners. Their use extends to furniture assembly, aerospace applications, and even in the creation of intricate electronics, showcasing their versatility and indispensable nature. Elevating your projects with the right M6 flat washers not only enhances structural durability but also reflects a commitment to quality and precision. When armed with the knowledge of material benefits, size compatibility, and optimal usage techniques, you establish a foundation of trust and authority in choosing the correct components for robust results. For professionals seeking to uphold their reputation and meet industry standards, relying on reputable suppliers with an established track record is paramount. Verified manufacturers offering detailed product specifications, rigorous testing standards, and compliance with international regulations ensure you invest in washers that meet or exceed expectations. Choosing M6 flat washers starts as a simple selection but evolves into a decision impacting the overall success of your engineering endeavors. With experience, expertise, authority, and trust as your guiding principles, you can navigate this choice with confidence, resulting in assemblies that stand the test of time and exemplify excellence.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News