Feb . 16, 2025 12:50

Back to list

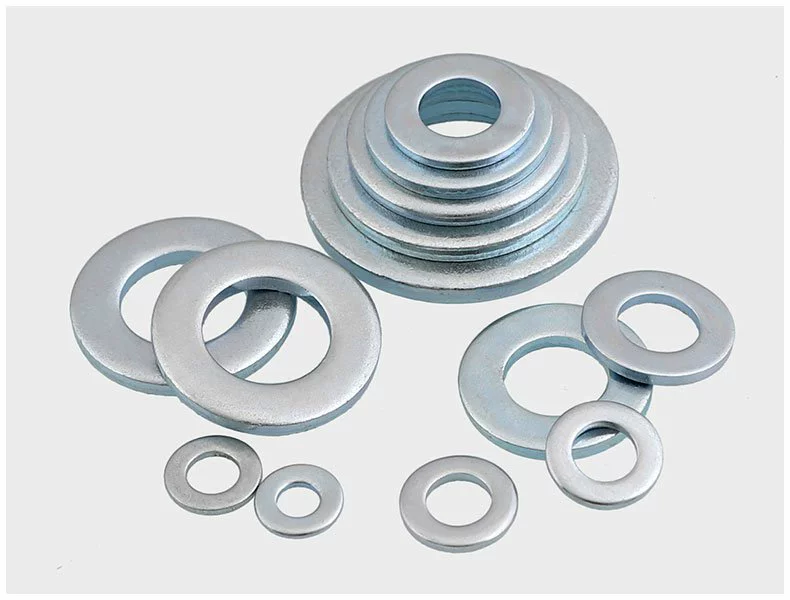

flat washer lug nuts

Flat washer lug nuts are integral components in various automotive and industrial applications, offering stability, durability, and safety. Understanding their functionality, application and the nuances of selecting the right ones can greatly enhance performance and security in these settings. This piece delves into the critical aspects of flat washer lug nuts, underlining their importance and offering insights into their selection and application.

Authoritativeness in selecting flat washer lug nuts is reflected in understanding the specific requirements of different applications. For instance, in high-performance or professional motorsports, the demands on these components are significantly heightened. The materials used must withstand not just sheer driving force but also resist corrosion and deformation under high stress and temperature conditions. This necessitates consultation and assessment from industry experts to ensure compliance with performance safety standards. Trustworthiness is established through this knowledge and application adherence. Mechanics and end-users rely heavily on the recommendations and installations made by professionals who use flat washer lug nuts. Ensuring that these components are sourced from reputable manufacturers not only fortifies the mechanic's reputation but also enhances consumer safety. Quality assurance processes, including material testing and compliance with international standards, can significantly impact trust; therefore, verifying these aspects with manufacturers is critical. In terms of practical experience, seasoned technicians will attest that the longevity and performance of flat washer lug nuts depend heavily on installation conditions and maintenance routines. Regular inspection for signs of wear, rust, and deformation is crucial to maintaining the highest safety standards. These inspections are part of the preventative maintenance practices that reliable service providers employ to avert potential catastrophes, thus underscoring the importance of experience in extending the practical lifespan of these components. Ultimately, flat washer lug nuts might appear as simple elements within the larger mechanical assembly, but their role is far-reaching. Their quality and the precision of their application reverberate through the entire system they are part of, affecting safety, performance, and longevity. For vehicle owners and industry practitioners alike, understanding the intricacies of these vital components translates into better decision-making and enhanced reliability in both personal and professional settings. As such, this knowledge underlies not just the components' functionality but also the broader context of its usage in ensuring vehicular and mechanical safety and efficiency.

Authoritativeness in selecting flat washer lug nuts is reflected in understanding the specific requirements of different applications. For instance, in high-performance or professional motorsports, the demands on these components are significantly heightened. The materials used must withstand not just sheer driving force but also resist corrosion and deformation under high stress and temperature conditions. This necessitates consultation and assessment from industry experts to ensure compliance with performance safety standards. Trustworthiness is established through this knowledge and application adherence. Mechanics and end-users rely heavily on the recommendations and installations made by professionals who use flat washer lug nuts. Ensuring that these components are sourced from reputable manufacturers not only fortifies the mechanic's reputation but also enhances consumer safety. Quality assurance processes, including material testing and compliance with international standards, can significantly impact trust; therefore, verifying these aspects with manufacturers is critical. In terms of practical experience, seasoned technicians will attest that the longevity and performance of flat washer lug nuts depend heavily on installation conditions and maintenance routines. Regular inspection for signs of wear, rust, and deformation is crucial to maintaining the highest safety standards. These inspections are part of the preventative maintenance practices that reliable service providers employ to avert potential catastrophes, thus underscoring the importance of experience in extending the practical lifespan of these components. Ultimately, flat washer lug nuts might appear as simple elements within the larger mechanical assembly, but their role is far-reaching. Their quality and the precision of their application reverberate through the entire system they are part of, affecting safety, performance, and longevity. For vehicle owners and industry practitioners alike, understanding the intricacies of these vital components translates into better decision-making and enhanced reliability in both personal and professional settings. As such, this knowledge underlies not just the components' functionality but also the broader context of its usage in ensuring vehicular and mechanical safety and efficiency.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News