Flat Head Torx Self-Tapping Screw Manufacturer and Supplier for Quality Fasteners

The Importance of Flat Head Torx Self-Tapping Screws in Modern Manufacturing

In the realm of manufacturing and construction, the choice of fasteners can significantly influence the quality, durability, and efficiency of a project. Among the various types of fasteners available, flat head Torx self-tapping screws stand out for their uniqueness and practicality. This article will explore the features, benefits, applications, and factors to consider when choosing flat head Torx self-tapping screws, emphasizing why they are a preferred choice in many industries.

What Are Flat Head Torx Self-Tapping Screws?

Flat head Torx self-tapping screws are specialized fasteners designed to create their own hole in materials such as metal, wood, and plastics during the installation process. The flat head refers to the shape of the screw's head, which allows for a flush finish once the screw is driven into the surface. The Torx designation indicates that the screw features a star-shaped drive system, providing enhanced torque transfer and reducing the risk of cam-out during installation.

Self-tapping screws are equipped with sharp threads that penetrate and displace material. This eliminates the need for a pre-drilled hole, which saves time and ensures a secure connection. These screws are particularly beneficial in environments where speed and efficiency are critical.

Advantages of Flat Head Torx Self-Tapping Screws

1. Enhanced Drive Efficiency The Torx drive design allows for high levels of torque to be applied without slipping. This means that users can work more quickly and efficiently, reducing overall labor costs.

2. Reduced Cam-Out Risk One of the common issues with traditional screw heads, such as Phillips or slotted designs, is cam-out, where the tool slips out of the screw head, damaging both the screw and the material. The Torx design minimizes this risk, providing a more reliable fastening solution.

3. Flush Finish The flat head design allows these screws to sit flush with the surface of the material, creating a clean and aesthetically pleasing finish. This is particularly important in applications where the visual appearance of the installation is crucial.

4. Versatility Flat head Torx self-tapping screws can be used in a variety of materials, including wood, metal, and composite materials. This versatility makes them suitable for numerous applications, from furniture assembly to electrical installations.

5. Durability These screws are generally made from high-quality materials such as stainless steel or hardened carbon steel, which enhances their strength and corrosion resistance. This durability is essential for applications exposed to the elements or harsh conditions.

flat head torx self tapping screw factory

Applications in Various Industries

Flat head Torx self-tapping screws find their application in multiple sectors. In the automotive industry, they are used for assembling different vehicle components where secure fastening is crucial for safety and performance. In electronics, these screws help connect parts of devices securely without the risk of loosening due to vibration.

Construction professionals also favor these screws for installing fixtures and fittings where a strong, flush connection is required. Additionally, in furniture manufacturing, they provide robust and clean finishes that are appealing to consumers.

Selecting the Right Screw Factors to Consider

When choosing flat head Torx self-tapping screws for your project, consider the following factors

1. Material Compatibility Ensure that the screw material is compatible with the materials being joined. For example, use stainless steel for outdoor applications to prevent rusting.

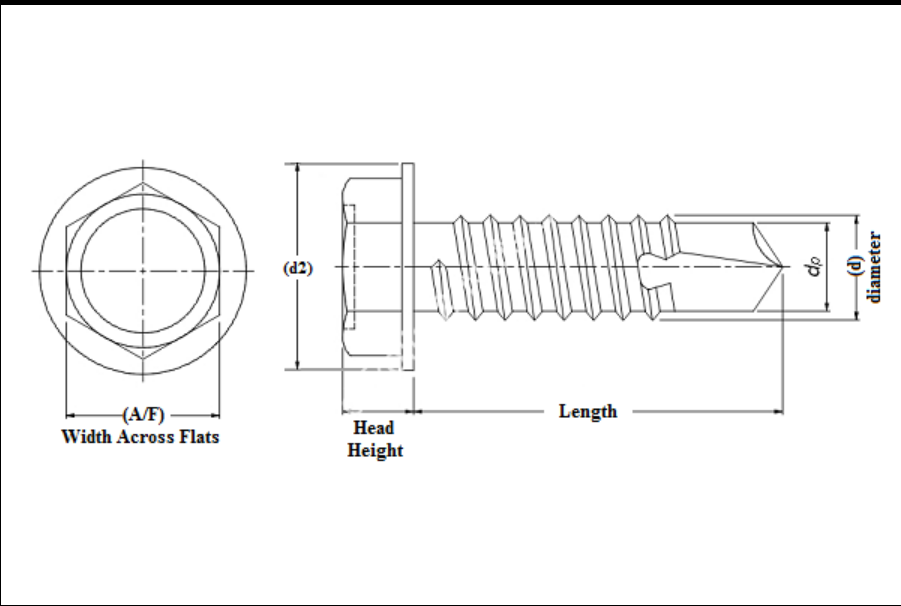

2. Screw Length and Diameter The size of the screw should be appropriate for the thickness of the materials being fastened. An oversized screw can damage the material, while an undersized screw may not provide adequate holding strength.

3. Coating For certain environments, a coating such as zinc plating can provide additional corrosion resistance. Always assess the environmental conditions before making a selection.

4. Drive Size Ensure that the right sized Torx driver is available, as using the incorrect size can lead to inefficiency and potentially damage the screw.

Conclusion

Flat head Torx self-tapping screws represent an excellent choice for fasteners in various applications, thanks to their unique features and benefits. Their ability to provide a secure and flush connection with minimal installation time makes them indispensable in modern manufacturing and construction. As industries continue to evolve, the demand for reliable and efficient fastening solutions will only grow, securing the flat head Torx self-tapping screw's place in the fastener market. Whether in automotive assembly, electronics, construction, or furniture manufacturing, these screws stand out as a testament to innovation and practicality in fastener design.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024