famous type b flat washer

Understanding the Importance of Type B Flat Washers

Flat washers are a commonly used component in various applications, serving a critical role in ensuring that fasteners hold securely and operate effectively. Among these, the Type B flat washer is especially notable for its distinct characteristics and advantages. This article will explore the significance of Type B flat washers, their applications, and considerations for selecting the right washer for your needs.

What is a Type B Flat Washer?

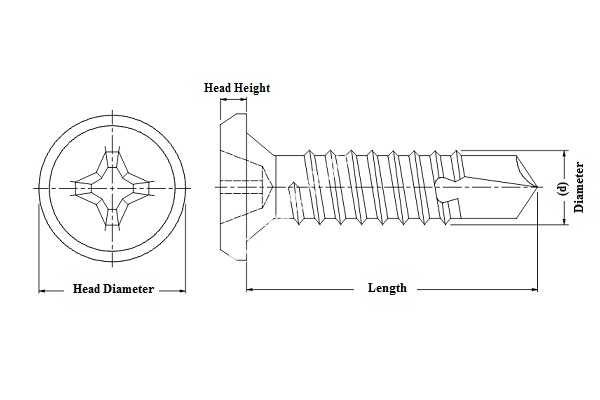

A Type B flat washer is typically characterized by its round shape and uniform thickness. It is designed to distribute the load of a threaded fastener, such as a bolt or screw, over a larger surface area. The increased surface area decreases the risk of damage to the material being fastened, which is particularly important in softer materials where indentation can occur.

The Type B flat washer generally has a larger outer diameter in comparison to its inner diameter. This design feature facilitates a stronger grip on the surface when the fastener is tightened, allowing for enhanced stability and structural integrity. They are usually made from a variety of materials, including stainless steel, carbon steel, and plastic, which can be selected based on the specific requirements of the application.

Applications of Type B Flat Washers

Type B flat washers are utilized in a wide array of industries and applications, ranging from construction and manufacturing to automotive and electronics. Here are some key applications that highlight their versatility

1. Construction In the construction industry, Type B flat washers are used to secure connections in structural assemblies. They help prevent bolts and screws from loosening over time, which is critical for maintaining the safety and longevity of buildings and infrastructure.

2. Automotive In automotive applications, these washers play an essential role in holding components like engine parts, chassis, and other critical elements in place. The ability to distribute load effectively ensures that even under high-stress conditions, components remain secure.

3. Electronics In the electronics sector, Type B flat washers are often used to secure circuit boards and other sensitive components. The use of non-conductive materials helps prevent short circuits and ensures that sensitive equipment operates reliably.

4. Manufacturing In manufacturing, flat washers are used in assembly lines to streamline production processes. They help reduce wear on components and contribute to the overall efficiency of manufacturing operations.

Benefits of Using Type B Flat Washers

famous type b flat washer

The benefits of using Type B flat washers are manifold

- Load Distribution By distributing the load evenly, these washers prevent damage to the substrate material and reduce the risk of fastener failure, which can result in costly repairs or safety hazards.

- Corrosion Resistance When made from stainless steel or other corrosion-resistant materials, Type B flat washers help prolong the life of assemblies exposed to moisture or harsh environments.

- Cost-Effective Although a relatively small component, flat washers are economical and can significantly improve the performance of fastener assemblies. They are a low-cost solution to many fastening problems.

Selecting the Right Type B Flat Washer

When selecting a Type B flat washer for a specific application, there are several important factors to consider

- Material The choice of material should align with the operating environment. For external applications, stainless steel is often preferred for its corrosion resistance, while carbon steel may be sufficient for indoor or dry environments.

- Size The size of the washer must match the fastener being used. Selecting the correct inner and outer diameter is essential for optimal performance.

- Thickness The thickness of the washer also plays a critical role in its effectiveness. Thicker washers can spread loads over a larger area, which may be necessary for certain applications.

- Industry Standards It’s advisable to adhere to industry standards for washers, such as those set by the American National Standards Institute (ANSI) or International Organization for Standardization (ISO), to ensure compatibility and safety.

Conclusion

In conclusion, Type B flat washers are a fundamental yet often overlooked component in various engineering and construction applications. Their ability to evenly distribute load, reduce wear, and enhance the stability of fastener assemblies makes them invaluable in a multitude of settings. Understanding their role, benefits, and the considerations for selection can lead to better design choices and improved performance in your projects. Whether you are involved in construction, automotive, manufacturing, or any other field that utilizes fasteners, Type B flat washers should be an essential part of your toolkit.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024