famous self tapping screw machine

The Evolution and Importance of Famous Self-Tapping Screw Machines

In the realm of manufacturing and assembly, self-tapping screws have revolutionized the way materials are joined together. At the heart of this innovation lies the famous self-tapping screw machine, a crucial piece of equipment that not only enhances efficiency but also ensures precision in a variety of applications. This article delves into the significance of self-tapping screws, the mechanics of the machines that produce them, and their impact on various industries.

Understanding Self-Tapping Screws

Self-tapping screws are specialized fasteners designed to cut their own threads as they are driven into a material, typically metals or plastics. This unique feature eliminates the need for pre-drilled holes, which significantly simplifies and accelerates the assembly process. With a variety of tip designs, such as pointed, blunt, or sharp, self-tapping screws can adapt to different materials and thicknesses, making them versatile components in various manufacturing sectors. Their widespread use can be observed in construction, electronics, automotive, and furniture industries, illustrating their pivotal role in modern assembly lines.

The Mechanics of Self-Tapping Screw Machines

Famous self-tapping screw machines are engineered to produce these fasteners with remarkable speed and precision. The machines operate through a series of automated processes that incorporate advanced technologies, ensuring that each screw meets stringent quality standards. Typically, the process begins with raw materials, often in the form of wire or rods, which are fed into the machine.

Once inside, the materials are cut to the desired length. Next, the machine engages in the critical step of forming threads onto the screw body. This is achieved through a combination of rotating dies and dies that mold the material into shape. After threading, heat treatment may be applied to enhance the screws' strength and durability.

The final stages of production include head formation and surface treatment, such as coating to resist corrosion. These processes are finely tuned to ensure that the screws produced are consistent in quality and ideally suited for their intended applications. Automation plays a significant role in this process, optimizing production speed and minimizing human error, which makes famous self-tapping screw machines indispensable in high-volume manufacturing.

famous self tapping screw machine

Impact on Industries

The introduction and refinement of self-tapping screw machines have had a profound impact on various industries. In construction, for instance, the ability to quickly and efficiently fasten components has led to significant reductions in labor costs and construction timelines. Similarly, in the electronics sector, the precision with which these screws can be produced and deployed contributes to the reliability and longevity of devices.

The automotive industry has also benefited from advancements in self-tapping screw machines, where the reliability of fasteners is critical to safety and performance

. The ability to have lightweight, strong, and corrosion-resistant screws facilitates the design of innovative vehicles that meet stringent safety standards.Future Trends

Looking ahead, the future of self-tapping screw machines seems bright, particularly with the integration of smart technologies. The implementation of IoT (Internet of Things) in manufacturing processes allows for real-time monitoring and data analysis, leading to continuous improvement in production efficiency and quality control.

As industries continue to evolve and demand faster, more reliable solutions, self-tapping screw machines will undoubtedly play a critical role in meeting these needs. Their ability to adapt to new materials, such as composites and advanced alloys, will further expand their applications and significance in tomorrow’s manufacturing landscape.

Conclusion

In conclusion, the famous self-tapping screw machine is a marvel of engineering that has revolutionized the way we approach assembly and manufacturing. As industries evolve and technology advances, these machines will continue to be at the forefront of innovation, ensuring that the world of fasteners remains robust, reliable, and adaptable to future challenges.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

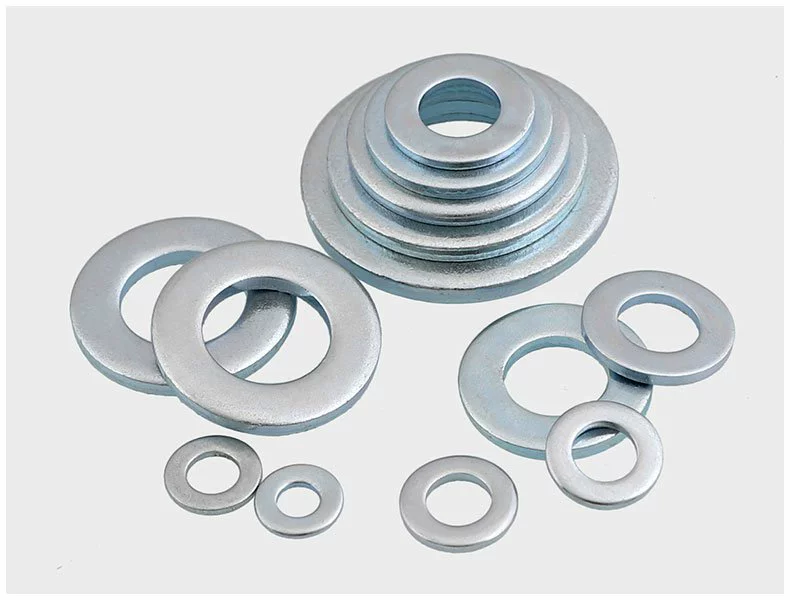

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024