famous self tapping screw cad

The Evolution and Importance of Self-Tapping Screws in Modern Manufacturing

Self-tapping screws have revolutionized the way we approach fastening in various manufacturing and construction sectors. Introduced in the mid-20th century, these screws have become indispensable in many applications, ranging from furniture assembly to building structures. Their unique ability to tap their own hole as they are driven into materials has not only saved time but also enhanced the efficiency of various processes.

What is a Self-Tapping Screw?

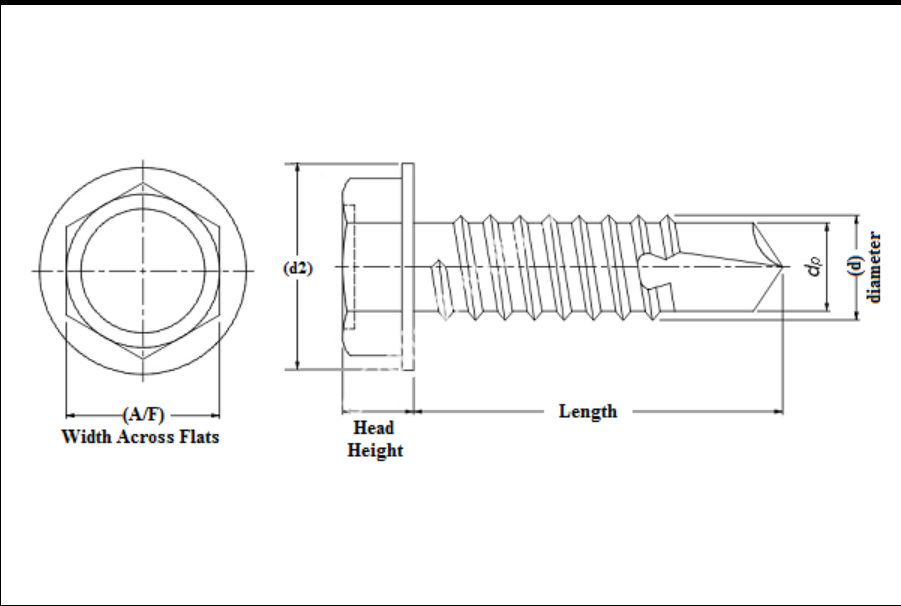

A self-tapping screw is a type of fastener that creates its own thread in the material into which it is driven, eliminating the need for a pre-drilled hole. These screws come in various designs, including slotted, Phillips, Torx, and more, ensuring compatibility with various tools and applications. They can be made from different materials, such as stainless steel, carbon steel, or aluminum, and can be coated for added corrosion resistance. The design and material choice often depend on the specific requirements of the project, such as strength, durability, and environmental conditions.

Types of Self-Tapping Screws

The two most common types of self-tapping screws are thread-cutting screws and thread-forming screws

.1. Thread-Cutting Screws These screws remove the material to create space for the thread. They are typically used in plastics or softer materials, allowing for a secure fit without compromising the integrity of the material.

2. Thread-Forming Screws Unlike thread-cutting screws, thread-forming screws displace material rather than cutting through it. This type is ideal for harder materials, such as metals, as it creates a tighter hold and is less likely to cause damage to the substrate.

Applications

famous self tapping screw cad

Self-tapping screws are used in a wide array of applications. In the construction industry, they are widely used for metal framing, HVAC applications, and siding, providing a quick and reliable fastening solution. In the automotive industry, self-tapping screws are utilized in assembling various parts efficiently. Furthermore, the DIY market has seen a surge in the use of these screws due to their ease of use and versatility.

Furniture manufacturers also benefit from self-tapping screws, as they allow for quick assembly and disassembly, which is a crucial feature in the flat-pack furniture movement. With the growing emphasis on sustainable practices, self-tapping screws made from recyclable materials are gaining popularity.

Benefits of Self-Tapping Screws

The advantages of self-tapping screws are numerous. First and foremost, they increase efficiency, reducing the time needed to complete a project. They eliminate the need for pilot holes in many cases, which not only saves time but also reduces the chance of misalignment and material damage.

Moreover, self-tapping screws provide a strong and secure hold, essential for both structural integrity and safety. The design of these screws allows for a consistent and reliable connection that can withstand vibrations and stress over time. Additionally, their versatility means that they can be used across different materials, whether it be wood, metal, or plastic.

Challenges and Considerations

Despite their many advantages, there are challenges associated with self-tapping screws. For instance, improper installation can lead to stripped screws or damaged materials. It is essential to use the correct type of screw for the material and application to avoid such issues. Moreover, while self-tapping screws can be incredibly effective, they may not always be the best choice for every application, particularly in high-strength environments, where other fastening methods like bolts or welding might be more appropriate.

Conclusion

In conclusion, self-tapping screws are a fundamental innovation in fastening technology that continues to play a vital role in various industries. Their ability to simplify the assembly process while providing reliable and strong fastening solutions makes them an essential component in modern manufacturing. As industries evolve and seek faster, cost-effective solutions, self-tapping screws will undoubtedly remain a key player in the future of fastening technologies. Whether you are a DIY enthusiast or a seasoned professional, understanding the benefits and applications of self-tapping screws is crucial in achieving optimal results in any project.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024