Specifications for M20 Flat Washer Dimensions and Applications in Various Industries

Understanding Famous M20 Flat Washer Dimensions

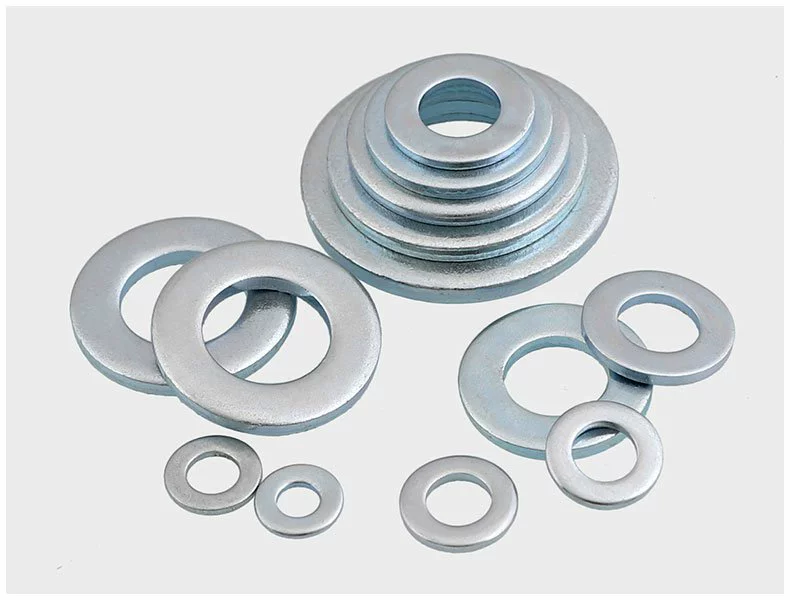

When it comes to fastening applications, the importance of selecting the right components cannot be overstated. Among these components, flat washers play a significant role in distributing load, reducing friction, and preventing damage to surfaces. In this context, the M20 flat washer is a popular choice among engineers and DIY enthusiasts alike. This article delves into the dimensions and specifications of the M20 flat washer, highlighting its significance in various applications.

What is an M20 Flat Washer?

The M in M20 denotes metric sizing, specifically referring to the diameter of the bolt or screw that the washer is intended for. The number 20 represents the nominal diameter in millimeters, which corresponds to an M20 bolt or screw. Flat washers are typically made from various materials, including stainless steel, carbon steel, and plastic, each offering different properties suitable for specific applications.

Dimensions of an M20 Flat Washer

The dimensions of an M20 flat washer can vary slightly based on manufacturing standards, but they generally adhere to the ISO 8765 and DIN 125 specifications. Below are the key dimensions associated with an M20 flat washer

1. Inner Diameter (ID) The inner diameter of a standard M20 flat washer is approximately 20.5 mm. This size is specifically designed to fit snugly around an M20 bolt, providing a proper fit to distribute the load evenly.

2. Outer Diameter (OD) The outer diameter typically ranges between 37 mm and 50 mm. A larger outer diameter enhances load distribution and minimizes the risk of deformation or damage to the surface being fastened.

3. Thickness The thickness of an M20 flat washer usually falls between 2 mm and 4 mm. Thicker washers offer greater strength and load-distributing capabilities, while thinner versions may be suitable for lighter applications.

famous m20 flat washer dimensions

4. Material Standards M20 flat washers can be made from various materials, impacting their physical properties and suitability for different environments. For instance, stainless steel washers offer excellent corrosion resistance, which is crucial for applications in humid environments. In contrast, carbon steel washers are more cost-effective but may require additional coatings for corrosion resistance.

5. Surface Finish The surface finish of a flat washer can also vary. Some may be plain, while others are coated with zinc or other materials to enhance their protective qualities. The choice of finish can affect the washer's durability and performance in specific environments.

Importance of Using the Correct Washer

Using the right size and type of washer is critical to ensuring the integrity of the fastening system. Flat washers help prevent the bolt or screw from pulling through the surface material, which can lead to structural failure. They also help distribute the load from the bolt across a larger surface area, which is particularly important in applications involving soft or malleable materials.

Furthermore, using the correct washer can prevent loosening. As components vibrate or experience thermal expansion and contraction, a flat washer’s role in providing friction can inhibit movement, ensuring that the assembly remains secure over time.

Applications of M20 Flat Washers

M20 flat washers are commonly used in various industries, including construction, automotive, and manufacturing. Their versatility makes them ideal for securing machinery, structural components, and various equipment. They are also prevalent in DIY projects, where they help ensure a secure and efficient assembly.

Conclusion

In conclusion, the M20 flat washer is an essential component in a multitude of fastening applications. Understanding its dimensions—namely, the inner diameter, outer diameter, and thickness—along with the materials and finishes available can significantly impact the effectiveness and longevity of a project. By ensuring the correct selection of flat washers, professionals and hobbyists alike can enhance the reliability and durability of their assemblies, thus achieving safer and more reliable outcomes in their applications.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024