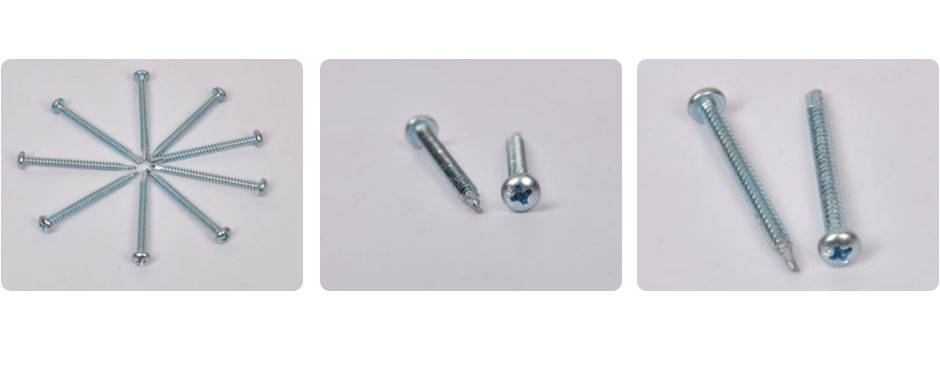

Famous Truss Head Self Tapping Screw - High Quality Fasteners for Every Project

The Famous Truss Head Self-Tapping Screw A Perfect Blend of Design and Functionality

In the realm of fasteners, the truss head self-tapping screw stands out as a remarkable innovation that combines efficiency, versatility, and strength. Widely used in various applications, from construction to electrical installations, these screws have gained a reputation for their unique design and functionality.

Design Features

The truss head self-tapping screw is characterized by its broad, flat head that provides a larger surface area. This feature is crucial as it distributes the load more effectively when applied, minimizing the risk of material damage during installation. The unique shape of the truss head also ensures a lower profile, making it ideal for situations where space is limited and a sleek finish is desired.

Another significant attribute is the screw’s sharp point and thread design, which allows it to create its own hole in the material, hence the term self-tapping. This eliminates the need for pre-drilling in many applications, saving both time and labor costs. The self-tapping ability makes these screws particularly valuable in fast-paced construction environments or DIY projects, where efficiency is paramount.

Material Composition

Truss head self-tapping screws are typically made from a variety of materials, including stainless steel, carbon steel, and other alloys. Stainless steel offers excellent corrosion resistance, making these screws perfect for outdoor applications or environments prone to moisture. On the other hand, carbon steel screws are often coated with zinc or other materials to enhance their durability and resistance to rust.

famous truss head self tapping screw

The choice of material greatly influences the screw's performance, allowing engineers and contractors to select the best option for their specific project requirements. This versatility is one of the reasons the truss head self-tapping screw is favored across various industries, including automotive, manufacturing, and electronics.

Applications

The applications of truss head self-tapping screws are extensive. They are commonly used in sheet metal work, where their ability to fasten without pre-drilling is particularly beneficial. In the construction industry, these screws are often employed in roofing, siding, and other structural applications due to their strength and reliability.

Moreover, they play a crucial role in the assembly of electrical components, securing connections that must endure vibrations and dynamic forces. The ability of these screws to maintain their integrity under such conditions has solidified their place as a trusted choice for electricians and engineers alike.

Conclusion

The truss head self-tapping screw symbolizes the intersection of innovation and practicality in the fastener industry. Its thoughtful design features, robust material choices, and broad range of applications have made it an indispensable tool in both professional and DIY settings. As industries continue to evolve, the reliance on such reliable fasteners is likely to persist, sealing the legacy of the truss head self-tapping screw as a staple in modern construction and manufacturing processes. With their ongoing development, one can only imagine what advancements the future holds for this remarkable fastener type.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024