Factory Production of Counter Sunk Flat Head Self Drilling Screws for Various Applications

The Rise of Countersunk Flat Head Self-Drilling Screws A Comprehensive Overview

In the fast-evolving world of construction and manufacturing, the importance of reliable fastening solutions cannot be overstated. Among these solutions, the countersunk flat head self-drilling screw has emerged as a vital component, favored for its versatility, efficiency, and secure fastening capabilities. This article delves into the characteristics, manufacturing process, applications, and the growing demand for these screws, with a particular focus on the factory innovations that drive their production.

Characteristics of Countersunk Flat Head Self-Drilling Screws

The countersunk flat head self-drilling screw features a distinct design that allows it to sit flush with the surface of the material when installed. This property is particularly valuable in applications where aesthetic finish and a smooth surface are crucial. The self-drilling mechanism, often equipped with a drill point that eliminates the need for pre-drilling, ensures faster installation and reduces the labor required on-site. These screws are typically made from durable materials like stainless steel or carbon steel, providing them with excellent resistance to corrosion and wear.

Manufacturing Process

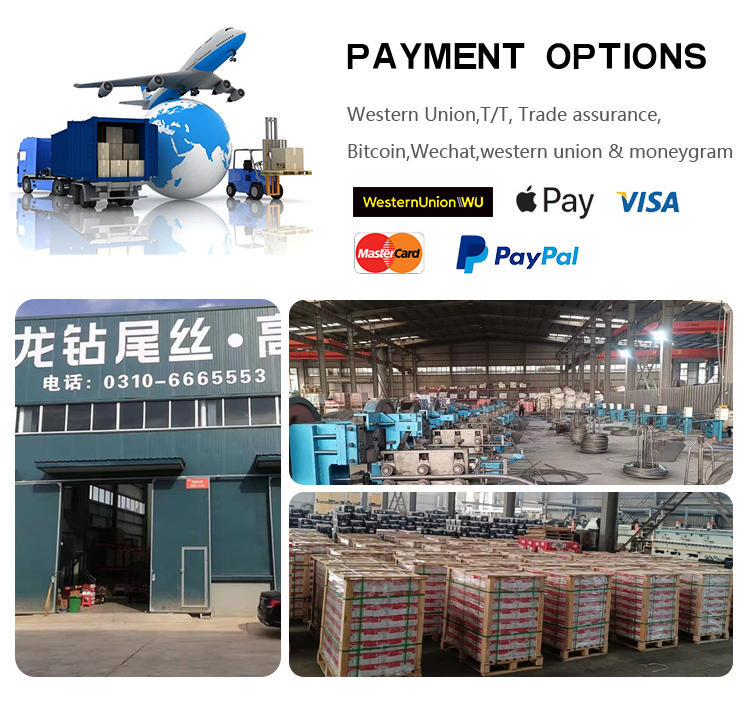

The production of countersunk flat head self-drilling screws involves several key steps. The process begins with the selection of high-quality raw materials, which are then shaped through advanced machining techniques. The head of the screw is designed to allow for optimal torque and grip, while the drill point is engineered to penetrate different materials—be it metal, wood, or plastic—without the need for pre-existing holes.

Once the screws are formed, they undergo a rigorous quality control process to ensure adherence to industry standards. Manufacturers often utilize automated machinery and robotics to enhance precision and efficiency, allowing for large-scale production while maintaining quality. Innovations in manufacturing technology, such as computer numerical control (CNC) and automated assembly lines, have significantly improved output efficiency and reduced costs, making it easier for factories to meet the rising demand for these fasteners.

Applications in Various Industries

countersunk flat head self drilling screw factory

Countersunk flat head self-drilling screws find use in a multitude of sectors, including construction, automotive, and electronics. In construction, they are frequently used in framing, roofing, and flooring applications, where secure fastening is paramount. Their ease of use reduces project timelines and labor costs, making them a preferred choice among contractors.

In the automotive industry, these screws are utilized for assembling various components, given their robust fastening capabilities and ability to resist vibration and shear stress. Furthermore, in the realm of electronics, these screws are often employed in device assembly and enclosures where aesthetics and functional integrity are critical.

Growing Demand and Future Outlook

The demand for countersunk flat head self-drilling screws is on the rise, driven by trends in construction and manufacturing that prioritize efficiency and quality. With an increase in construction projects and the expansion of manufacturing capabilities globally, factories producing these screws are under continuous pressure to innovate and enhance their production processes.

Furthermore, as environmental awareness grows, manufacturers are exploring sustainable materials and eco-friendly practices to meet regulatory standards and consumer preferences. The future of countersunk flat head self-drilling screws is not only about meeting demands but also about contributing to a more sustainable manufacturing landscape.

Conclusion

In conclusion, countersunk flat head self-drilling screws play a crucial role in various industries, driven by their efficiency, durability, and aesthetic appeal. As factories continue to enhance their manufacturing processes, the future of these fasteners looks promising. With ongoing innovations and increased demand, the countersunk flat head self-drilling screw will remain an indispensable component in both existing and emerging applications, shaping the future of fastening solutions.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024