Exporters of SAE Flat Washer Specifications and Standards for Industrial Applications

Exploring SAE Flat Washer Specifications and Their Export Market

In the world of industrial applications, the importance of hardware components—particularly fasteners—cannot be overstated. Among these, SAE flat washers play a crucial role. Understanding the specifications and export market for these washers is essential for manufacturers, exporters, and end-users alike.

What are SAE Flat Washers?

SAE flat washers are flat, circular discs made of metal or plastic that are used to distribute the load of a fastener, such as a bolt or a nut. Their primary function is to prevent damage to the surface being fastened, ensuring even load distribution and enhancing assembly integrity. The Society of Automotive Engineers (SAE) has established standardized measurements and specifications that define the dimensions, materials, and properties of these washers.

SAE Washer Specifications

SAE flat washers are designed to meet specific criteria that ensure their effectiveness in various applications. Common specifications (such as SAE J403, SAE J429, etc.) dictate materials, mechanical properties, and dimensions.

1. Materials SAE flat washers are typically made from steel, stainless steel, brass, or other corrosion-resistant materials. The choice of material often depends on the application environment, with stainless steel being popular in outdoor and marine applications due to its resistance to rust and corrosion.

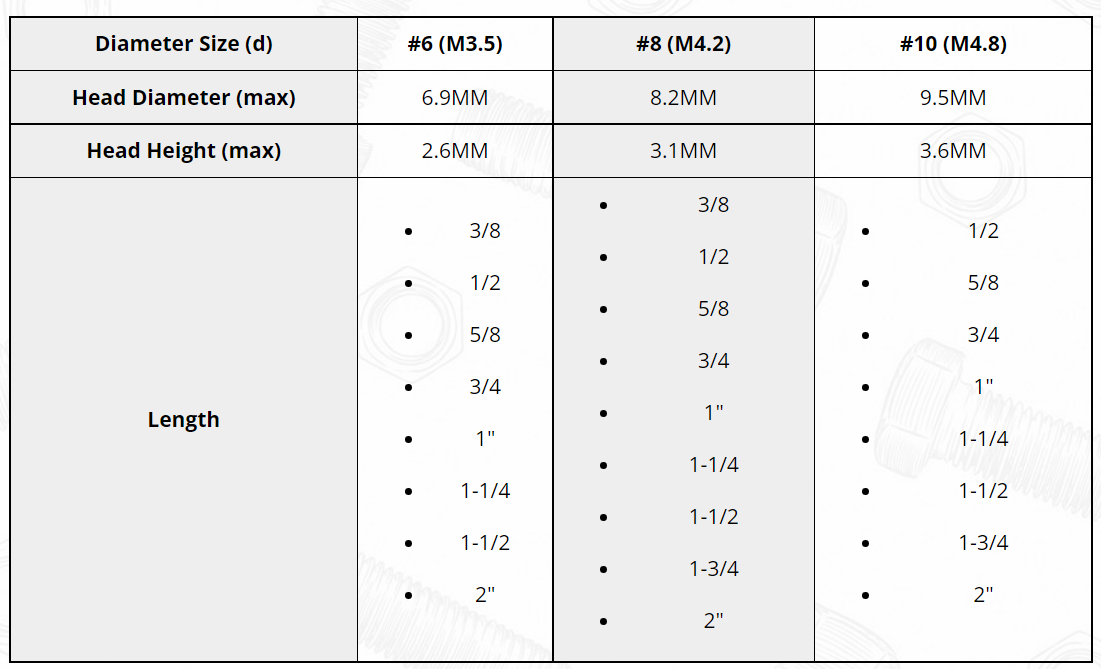

2. Dimensions The size of an SAE flat washer is determined by its inner diameter (ID), outer diameter (OD), and thickness. Common sizes range from 1/4 inch to 1 inch and beyond. It is crucial for washers to match the bolt diameter to ensure proper fitting.

3. Mechanical Properties Washers may also be classified based on their tensile strength, hardness, and resistance to deformation under load. These properties are critical in high-stress environments, such as automotive and aerospace industries.

Export Market for SAE Flat Washers

sae flat washer specifications exporters

The global demand for SAE flat washers continues to grow, driven by several factors

1. Industrial Growth As industries expand, the need for reliable fasteners and hardware components increases. Construction, automotive, and manufacturing sectors are significant consumers of SAE flat washers.

2. Globalization Many manufacturers are shifting focus to export markets, seeking opportunities beyond their local regions. Countries such as China, India, and Germany are leading exporters of these washers, capitalizing on their production capabilities and technological advancements.

3. Standards and Compliance Exporters must ensure their products meet international standards. Compliance with SAE specifications, as well as other regional standards (like ISO), is critical for international trade. This adherence builds trust with foreign customers and strengthens market position.

4. Customization Increasingly, customers seek customized solutions tailored to their specific requirements. Exporters who can provide a range of variations in terms of size, material, and finishing will find a competitive edge in the international market.

Challenges in the Export of SAE Flat Washers

While the export market for SAE flat washers presents lucrative opportunities, it is not without challenges. Regulatory compliance can be complex, with different countries imposing various standards and import duties. Fluctuations in raw material prices also influence production costs, affecting profitability.

Quality assurance is paramount. Manufacturers need to implement stringent quality control measures to ensure their products meet established specifications consistently. Failure to do so can result in costly returns, reputational damage, and loss of customers.

Conclusion

SAE flat washers are essential components in countless applications across various industries. Understanding their specifications is crucial for manufacturers and exporters looking to succeed in the competitive global market. By focusing on quality, compliance, and customization, exporters can navigate challenges and capitalize on the growing demand for these vital components. As industries continue to evolve, the role of SAE flat washers will remain significant, providing both structural support and operational efficiency.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024