Exploring the Global Market for 8% Diameter Self-Tapping Screw Exporters and Their Growth Potential

Understanding the Market for 8% Self-Tapping Screw Diameter Exporters

In the realm of fasteners, self-tapping screws play a critical role, offering efficiency and convenience in various applications. The 8% self-tapping screw diameter has emerged as a significant segment within this market due to its versatility and reliability in construction, automotive, and consumer goods industries. This article explores the dynamics of this growing market, focusing on exporters, demand trends, and competitive advantages.

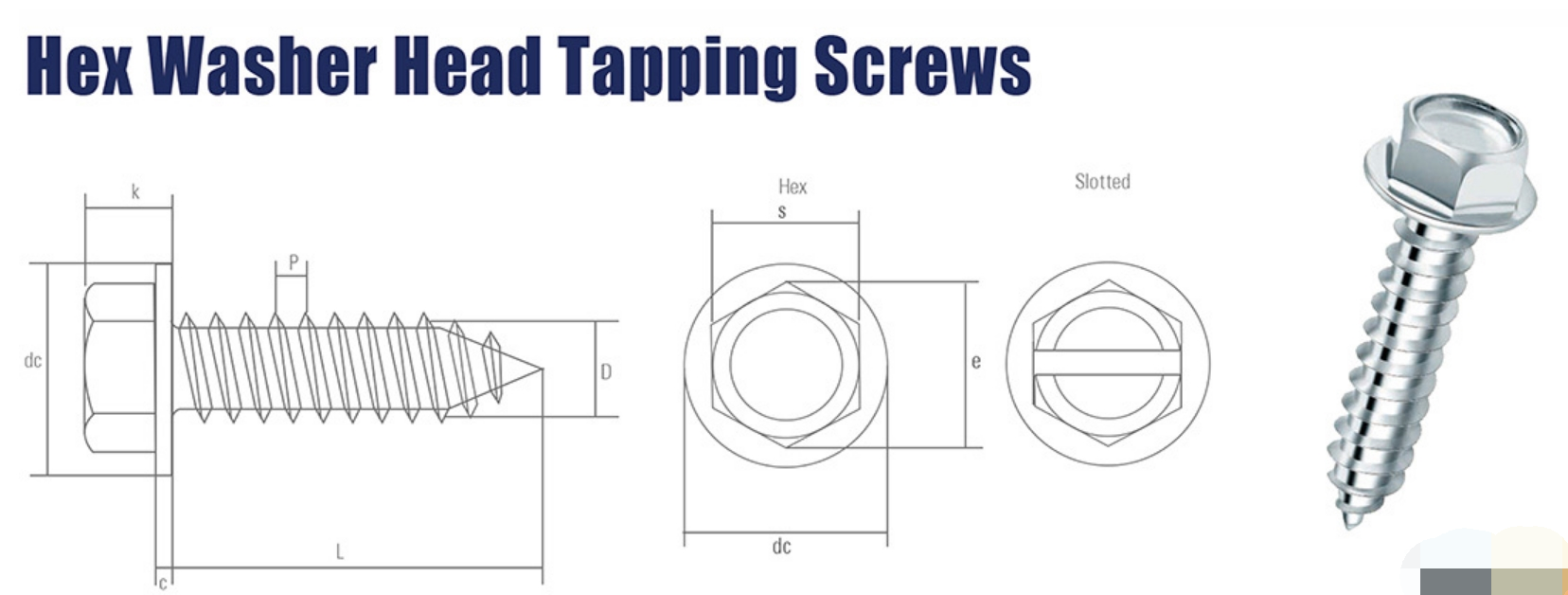

Self-tapping screws are designed to create their own hole when driven into materials, such as wood, metal, or plastic. This feature eliminates the need for pre-drilling, which can save time and labor costs. The 8% diameter specification signifies the screw’s size, which typically falls within a range suitable for medium to heavy-duty applications. As industries look for efficient fastening solutions, the demand for screws of this dimension has seen a notable increase.

Understanding the Market for 8% Self-Tapping Screw Diameter Exporters

One of the key factors driving the export market is the rising construction and manufacturing sectors globally. As infrastructure projects escalate in developing regions and manufacturing processes become more complex, the need for reliable fastening solutions such as self-tapping screws is paramount. Exporters are well-positioned to meet this demand by offering a wide variety of self-tapping screws tailored to specific industrial requirements.

8 self tapping screw diameter exporters

Additionally, the rise of e-commerce has transformed the way exporters operate. Many companies have established online platforms to reach international clients directly. This shift allows for greater transparency in pricing and accessibility for customers across the globe. With comprehensive catalogs and customization options, exporters of 8% self-tapping screws can cater to the specific needs of diverse industries, enhancing their competitive edge.

Quality control is another critical aspect of the export market. To maintain a reliable reputation, exporters must adhere to stringent quality standards. This involves rigorous testing of screws to ensure durability, corrosion resistance, and overall performance. Exporters who invest in advanced manufacturing technologies and quality assurance processes are more likely to stand out in a crowded market. Certification from recognized authorities can also bolster their reputation and appeal to quality-conscious customers.

Sustainability is becoming an increasingly vital concern in the fastener industry, including the self-tapping screw sector. As global attention shifts towards environmentally friendly practices, exporters are exploring the use of recycled materials and sustainable manufacturing processes. By integrating eco-friendly practices, exporters not only contribute to environmental conservation but also meet the preferences of a growing segment of environmentally conscious consumers.

In conclusion, the market for 8% self-tapping screw diameter exporters is poised for growth, driven by demand from various industries and the evolving nature of the global supply chain. Exporters that embrace quality, innovation, and sustainability will find ample opportunities in this competitive landscape. As infrastructure developments continue and manufacturing demands rise, the role of self-tapping screws will undoubtedly remain pivotal in shaping the future of fastener solutions worldwide.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024