Exploring the Design and Application of Popular Self-Tapping Screw 3D Printable Models for Engineers

The Famous Self-Tapping Screw A 3D Model Exploration

In the vast world of hardware and manufacturing, the self-tapping screw stands out as a remarkable invention that has revolutionized the assembly process in numerous industries. With its unique design, this screw can create its own hole as it is driven into a material, thus eliminating the need for pre-drilling. In the realm of 3D modeling, the self-tapping screw presents an intriguing subject, combining engineering excellence with artistic design principles.

Understanding Self-Tapping Screws

A self-tapping screw is characterized by its sharp tip and threads that are precisely designed to cut into a substrate material as it is installed. Typically made from steel or other durable materials, these screws have found applications in woodworking, metalworking, and even in the assembly of electronic devices. The ability to create a secure hold without additional tools or steps is what makes self-tapping screws invaluable in modern manufacturing and DIY projects.

The 3D Modeling Process

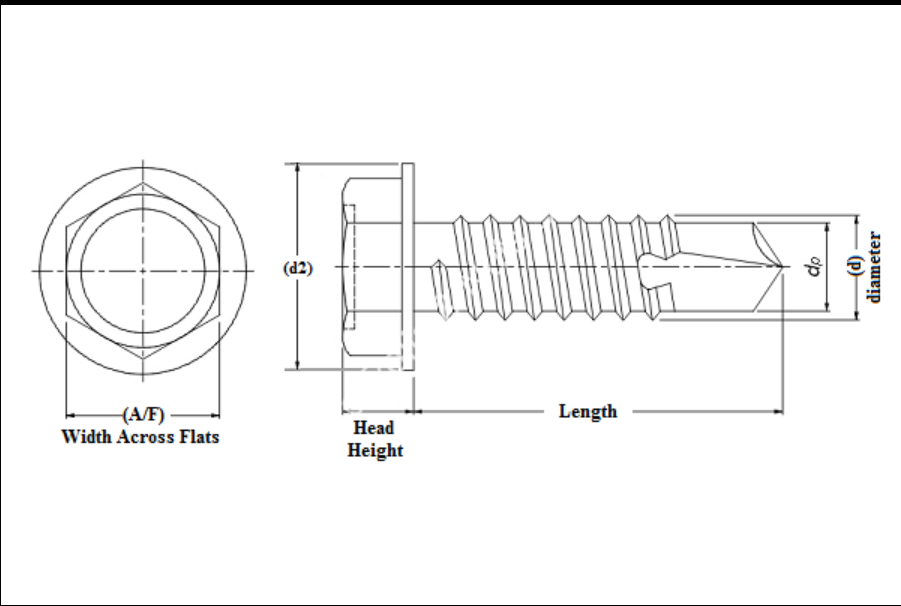

Creating a 3D model of a self-tapping screw involves several crucial steps, each emphasizing the screw's distinctive features. Using CAD (Computer-Aided Design) software, designers can replicate the geometry of the screw accurately. This process begins with defining the screw's dimensions, such as the diameter, length, and thread pitch. The helical thread design is particularly critical, as it provides the engagement required for efficient fastening.

Once the basic shape is established, the next step involves adding details such as the screw head shape, which can vary from Phillips to slotted or hex designs. This variation not only influences the screw's functionality but also its aesthetic appeal. In 3D modeling, texture and material properties can also be simulated, allowing designers to visualize how the screw will appear in a real-world application.

famous self tapping screw 3d model

Applications of the 3D Model

A well-crafted 3D model of a self-tapping screw serves multiple purposes. In the prototyping phase, engineers can integrate these models into their designs to assess compatibility with other components. For educational purposes, the model provides a tool for teaching students about the principles of fastening, mechanics, and material science. Furthermore, in marketing, realistic 3D representations of self-tapping screws can enhance product listings, making them more appealing to potential buyers by providing a clearer understanding of the product.

Enhancing Creativity in Design

3D modeling not only preserves the functional aspects of self-tapping screws but also encourages creativity. Designers can experiment with new shapes, materials, and finishes that could enhance the screw's performance or aesthetic appeal. For instance, an innovative design might incorporate a wider head for increased torque or unique aesthetic patterns that make the screw aesthetically pleasing without compromising its functionality.

Conclusion

The self-tapping screw is more than just a fastener; it embodies the intersection of engineering and design. Through the lens of 3D modeling, it transforms into a subject of both functional analysis and creative expression. As industries continue to evolve, the demand for efficient and reliable fastening solutions like self-tapping screws will only increase, making it essential for designers and engineers to explore the full potential of this remarkable hardware component through advanced modeling techniques. This not only allows for ongoing innovation but also fosters a deeper appreciation of the integral role screws play in modern technology and construction.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024