Exploring Leading Suppliers of Self-Tapping Screws for Your Manufacturing Needs and Projects

Understanding Self-Tapping Screws and Their Suppliers

In the world of fasteners, self-tapping screws play a crucial role, providing a reliable and efficient solution for various construction and engineering projects. Unlike traditional screws that require a pre-drilled hole, self-tapping screws are designed to create their own mating thread in the materials they are driven into. This unique feature not only saves time but also enhances the overall integrity of the assembly, making them a favored choice among manufacturers and builders alike.

What Are Self-Tapping Screws?

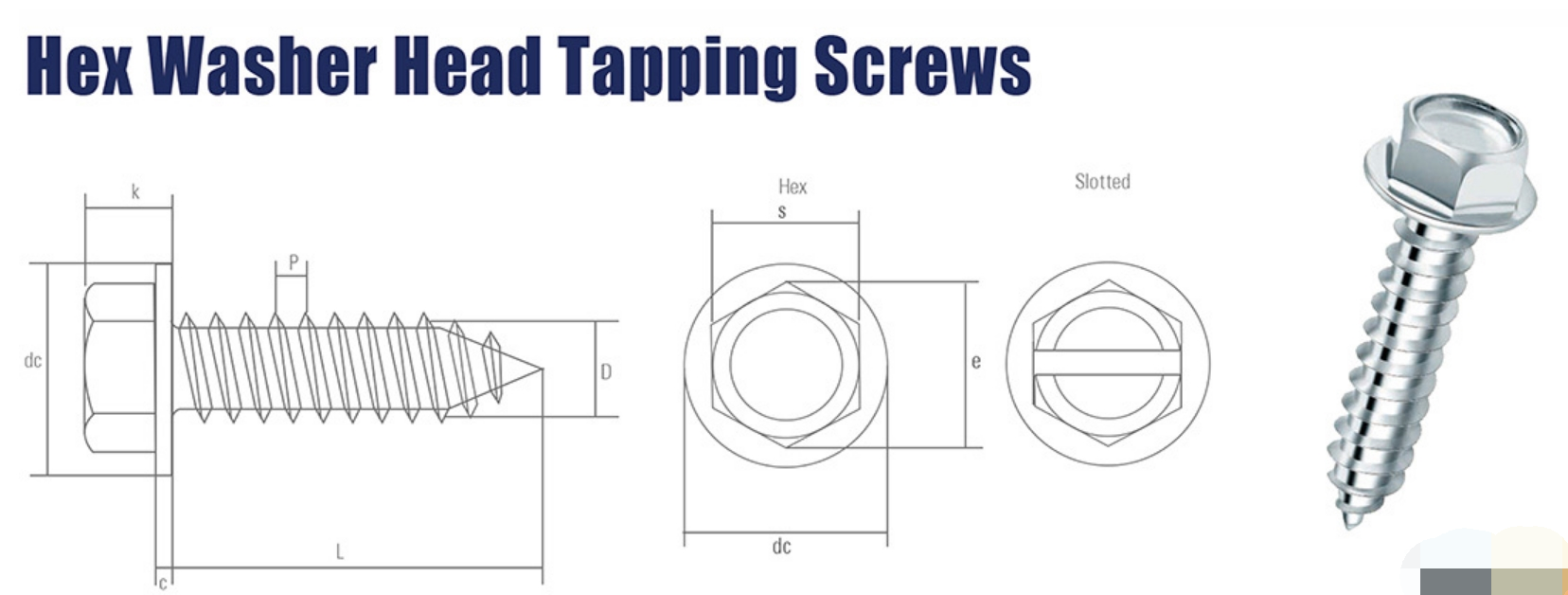

Self-tapping screws are characterized by their sharp, pointed tips and various thread designs which allow them to cut into materials such as metal, plastic, and wood. Their design typically includes a hardened tip and a thread that extends to the end of the screw, allowing for efficient penetration and fastening. There are several types of self-tapping screws, including thread-cutting screws that remove material as they are driven in and thread-forming screws that displace material to create a tight fit.

These screws are available in various sizes, materials, and coatings, providing flexibility for different applications. Common materials include stainless steel, carbon steel, and brass, while coatings might include zinc plating or black oxide, depending on the desired corrosion resistance and finish.

Importance of Selecting the Right Supplier

When considering the use of self-tapping screws for a project, selecting the right supplier is critical. The quality of screws can significantly impact the durability and performance of the final product. Here are a few key factors to consider when choosing a self-tapping screw supplier

picture of self tapping screw suppliers

1. Quality Assurance A reputable supplier will adhere to strict quality control measures, ensuring that every screw meets industry standards. Look for suppliers who offer certifications and guarantee their products’ quality.

2. Product Range Suppliers that offer a wide variety of self-tapping screws will be better equipped to fulfill specific project needs. It's beneficial to work with a supplier who has the capacity to provide different sizes, materials, and types of screws.

3. Customization In some cases, projects may require customized screws to meet unique specifications. Suppliers that offer customization options can be invaluable in providing the right solution for specific engineering challenges.

4. Technical Support A knowledgeable supplier can significantly ease the purchasing process. Technical support will help you select the right screws for your application and troubleshoot any issues that might arise.

5. Pricing and Delivery Cost-effectiveness is an essential aspect of procurement. Compare prices from different suppliers but be cautious; the cheapest option may not always guarantee the best quality. Timely delivery is also critical to ensure your project stays on schedule.

Conclusion

Self-tapping screws are an indispensable component in various industries, enhancing efficiency in assembly and construction processes. Choosing the right supplier for these fasteners is crucial, as the quality and variety of screws can significantly affect the outcome of a project. By focusing on suppliers that emphasize quality, offer a wide range of products, provide customization, deliver exceptional technical support, and maintain competitive pricing, organizations can enhance their operations and ensure lasting success. As the demand for self-tapping screws continues to rise in various sectors, collaborating with reliable suppliers becomes more important than ever.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024