drywall won't hold screw factories

Understanding Why Drywall Won't Hold Screws Causes and Solutions for Factories

Drywall, commonly known as gypsum board, has become a staple in modern construction. While it is favored for its lightweight, cost-effective, and easy-to-install qualities, many users encounter a frustrating issue screws not holding properly in drywall. This challenge can manifest in various settings, particularly in factories where efficiency and safety are paramount. Understanding the reasons behind this problem and exploring solutions can significantly enhance construction practices and overall project outcomes.

The Basics of Drywall

Drywall is composed of a core made of gypsum plaster sandwiched between two sheets of heavy paper. It is available in various thicknesses and sizes, with the standard being 1/2 inch thick. Drywall is primarily used for interior walls and ceilings and is appreciated for its smooth surface that allows for easy finishing. However, the installation of fixtures, cabinets, and other structural elements often requires fastening into drywall, which can lead to complications if not done correctly.

Reasons Screws Won't Hold in Drywall

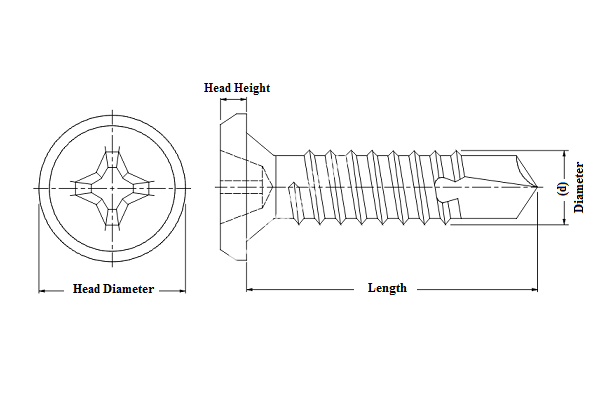

1. Incorrect Screw Type One of the most common mistakes is using the wrong type of screw. Regular wood screws or self-tapping screws are not designed for drywall. Instead, drywall screws, which have a sharp point and are specifically made to grip the material securely, should always be utilized. Using improper screws can lead to them stripping out or failing to hold weight.

2. Over-tightening When screws are over-tightened, they can break through the paper surface of the drywall, compromising their grip on the material. This issue not only results in a weak hold but may also damage the drywall, leading to further issues down the line. Proper installation involves just enough torque to ensure a snug fit without risking damage to the board.

3. Moisture Exposure Drywall is naturally susceptible to moisture, which can weaken its structure. Factory environments may expose drywall to humidity or leaks, causing it to sag or crumble around screw holes. Using moisture-resistant drywall in areas prone to dampness is essential for maintaining screw integrity.

4. Improper Installation Techniques The method of installation plays a crucial role in how well screws hold. If screws are placed too close to the edges of the drywall, they risk pulling out. Similarly, placing screws too far apart can result in insufficient support. It is recommended to space screws no more than 16 inches apart for standard applications.

drywall won't hold screw factories

5. Structural Limitations In some cases, drywall may not be suitable for heavy applications. When dealing with significant weight loads (like cabinetry), it’s often necessary to locate and secure screws into the underlying studs. Failing to do so results in drywall being the only support, leading to screw failure.

Solutions for Better Screw Retention

1. Use the Right Products Always select screws specifically designed for drywall applications. Consider using toggle bolts or anchors for heavier loads, as these products distribute weight more evenly across the drywall surface.

2. Follow Installation Guidelines Familiarize yourself with proper installation techniques to optimize screw placement and avoid over-tightening. Refer to manufacturer guidelines to ensure adherence to best practices.

3. Choose Moisture-Resistant Materials In environments where moisture is a concern, use moisture-resistant drywall. This product is specially treated to withstand humidity, reducing the risk of screws loosening over time.

4. Consider Alternate Fastening Methods For heavier fixtures, consider using additional frameworks, such as wooden blocking or metal brackets, to distribute weight more evenly and provide a stronger foundation for fastening.

5. Regular Maintenance Periodic inspections of installed drywall are essential to catch any issues early. Look for signs of sagging, moisture damage, or visible wear around screw holes and address these proactively.

Conclusion

Drywall remains a preferred choice in construction for its versatility and efficiency. However, the challenge of screws not holding properly can lead to significant frustrations in factory settings. By understanding the underlying causes and implementing effective solutions, it is possible to enhance the performance of drywall installations. Ultimately, attention to detail and adherence to best practices will ensure that projects remain safe, stable, and efficient, benefitting manufacturers and builders alike.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024