drywall screw specifications quotes

Understanding Drywall Screw Specifications

When it comes to drywall installation, the choice of screws is critical. Drywall screws are specifically designed to secure drywall to framing materials such as wood or metal studs. Their unique specifications make them distinct from other types of screws, and understanding these details is essential for any construction or renovation project.

Types of Drywall Screws

Drywall screws can be classified into two main types fine thread and coarse thread. Fine thread screws are typically used for metal framing. They are designed to penetrate the metal without stripping, providing a solid grip. On the other hand, coarse thread screws are ideal for wooden studs, as they allow for faster installation and better holding strength in softer materials.

Length and Size

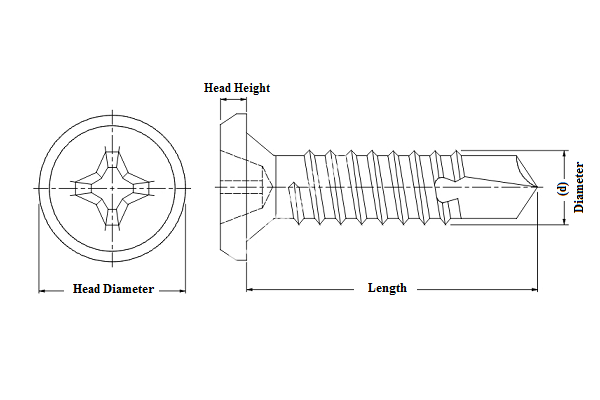

Drywall screws come in various lengths, commonly ranging from 1 to 3 inches. The most popular lengths for standard drywall sheets (which are typically ½ inch thick) are 1 1/4 inch and 1 5/8 inch screws. When choosing the length of the screw, it is important to consider the thickness of the drywall and the underlying material. A general rule of thumb is that the screw should penetrate at least ¾ inch into the framing material for optimal holding power.

The diameter of drywall screws is also a significant factor. Most screws for drywall installations feature a 6 or 8 gauge size. The choice between these sizes often depends on personal preference and project requirements, but it is crucial to maintain consistency in screw size throughout the project for uniformity and strength.

Head Types

drywall screw specifications quotes

The head of a drywall screw is designed to provide a finished appearance and prevent the screw from popping out over time. Common head types include bugle and pan heads. Bugle head screws are the most frequently used in drywall installation because their shape allows them to sink into the drywall without tearing the paper face, creating a flush surface that can be easily covered with joint compound. Pan head screws, while less common, can be used in applications where a more substantial head is necessary.

Coating and Finish

To enhance durability and reduce the risk of rust or corrosion, drywall screws are often coated with a special finish. The most common types of coatings are black phosphate, zinc plating, and epoxy coating. Black phosphate screws are popular for their anti-corrosive properties, while zinc-plated screws are typically used in more humid environments. Epoxy-coated screws offer maximum corrosion resistance and are suitable for outdoor applications or areas with higher moisture levels.

Application Techniques

Proper installation techniques greatly affect the performance of drywall screws. It's advisable to use a power drill with a screw-driving attachment for efficiency. The screw should be driven straight into the stud without over-penetrating, which can damage the drywall paper and weaken the holding power. When installing, aim to place screws approximately 12 inches apart along the edges of the drywall and about 16 inches in the field (the center area of the panel).

Conclusion

Understanding drywall screw specifications is crucial for achieving a successful installation. From selecting the right type and length to considering the coating and installation technique, informed choices lead to a more durable and aesthetically pleasing outcome. Whether you are a contractor or a DIY enthusiast, grasping these details will help ensure that your drywall projects are completed efficiently and effectively.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024