drywall ceiling screw pattern exporters

Understanding the Drywall Ceiling Screw Pattern A Guide for Exporters

When it comes to drywall installation, particularly on ceilings, one critical aspect that ensures both structural integrity and aesthetic appeal is the fastening technique used—specifically, the screw pattern. For exporters involved in the construction materials sector, understanding the drywall ceiling screw pattern is essential for meeting international standards and customer demands. This article explores the importance of proper screw patterns in drywall installation, the factors influencing these arrangements, and best practices for exporting drywall products.

The Importance of a Proper Screw Pattern

The screw pattern in drywall installation is not merely a matter of preference; it significantly affects the overall effectiveness of the drywall, especially on ceilings. A well-planned screw pattern prevents sagging and cracking over time. It helps distribute the weight of the drywall evenly and ensures that seams are adequately secured, which is crucial for achieving a smooth finish. Moreover, adhering to specific patterns can also enhance sound insulation and fire resistance—qualities that are often key selling points for customers in the construction industry.

Common Screw Patterns

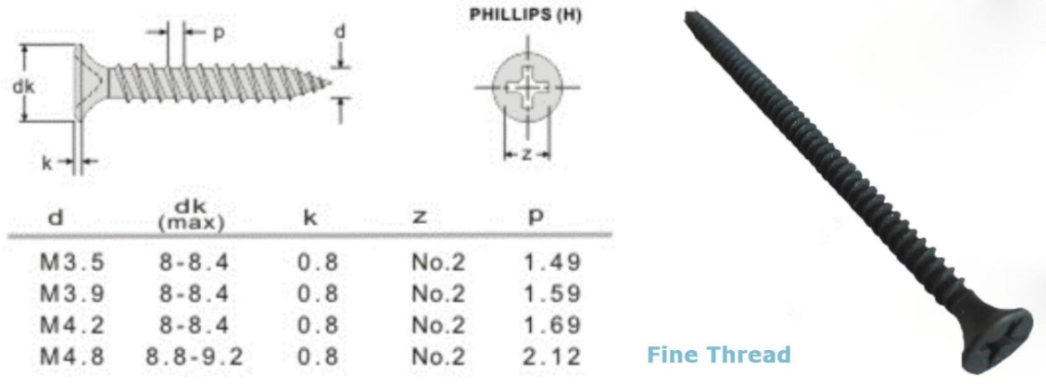

Typically, the standard screw pattern for drywall ceilings involves placing screws every 12 to 16 inches along the edges and about 16 inches in the field (the interior areas of the panel). For ceilings, it's particularly important to ensure that screws are installed straight and at the appropriate depth—typically, the screw head should lie just below the drywall surface without breaking the paper. Proper spacing and alignment are essential for creating a secure and stable surface.

In certain cases, factors such as the thickness of the drywall, type of screws used, and the specific application (e.g., residential vs. commercial buildings) can influence the recommended screw pattern. As such, exporters must be well-versed in these variables to provide precise recommendations for their products.

Factors Influencing Screw Patterns

When considering drywall screw patterns, several factors come into play

drywall ceiling screw pattern exporters

1. Material Type Different drywall materials (e.g., moisture-resistant, fire-resistant) may require varying techniques. Understanding the properties of the material is crucial. 2. Environmental Conditions Regions with higher humidity or extreme temperatures can influence the choice of drywall and its fastening patterns, as these conditions can cause materials to expand or contract. 3. Local Building Codes Exporters must stay informed about local and international building regulations that dictate specific installation practices to ensure compliance and avoid costly penalties. 4. Customer Preferences Some clients may have specific aesthetic or functional requirements that influence the screw pattern; being flexible and knowledgeable can foster stronger client relationships.

Best Practices for Exporting

For exporters focusing on drywall materials and accessories, particularly screws, it's important to adhere to best practices to ensure product quality and customer satisfaction

1. Educate Your Clients Provide clear guidelines and resources on recommended screw patterns for different applications. Consider offering workshops or e-learning modules.

2. Quality Assurance Ensure that your drywall products and screws meet international standards for fire safety, moisture resistance, and durability.

3. Tailored Offerings Different markets may have different needs, so offer customizable solutions that cater to specific construction practices or preferences in various regions.

4. Stay Current Regularly update your knowledge about new innovations in drywall installation and any changes in building codes across various markets.

5. Build Relationships Establish strong connections with local contractors and builders to gain insights into regional practices. This can also help create a reliable feedback loop for improving your product offerings.

In conclusion, understanding the drywall ceiling screw pattern is vital for exporters to navigate the complexities of the construction materials market. By focusing on quality, education, and compliance, exporters can position themselves as trusted partners in the drywall industry, ensuring that their products meet the diverse needs of customers worldwide.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024