drywall screw anchor types factories

Understanding Drywall Screw Anchor Types and Their Manufacturing

Drywall screw anchors play a pivotal role in securing objects to drywall, making them essential for both residential and commercial construction. These anchors are specially designed to handle a variety of loads and provide stable support for different applications. In this article, we will explore the types of drywall screw anchors, their manufacturing processes, and the importance of choosing the right type for specific needs.

Types of Drywall Screw Anchors

There are several types of drywall screw anchors, each designed for specific weight capacities and applications. Below are some of the most common types

1. Plastic Expansion Anchors These are light-duty anchors that are typically made of plastic. They expand when a screw is driven into them, creating a snug fit within the drywall. They are ideal for hanging lightweight items such as pictures and small decor.

2. Metal Expansion Anchors Also known as toggle bolts, these anchors feature a metal sleeve that expands behind the drywall once the screw is inserted. This provides a more secure hold and is suitable for medium-weight items, including shelves and brackets.

3. Threaded Anchors These anchors are screw-like devices that can be directly screwed into the drywall. They create their own threads, allowing for easy insertion and removal. Threaded anchors are great for hanging heavier items, such as TVs and cabinets.

4. Self-Drilling Anchors Known for their ease of use, self-drilling anchors are designed to be installed without the need for a pre-drilled hole. They feature sharp tips that cut into the drywall as they are screwed in. These anchors are strong and can support medium to heavy loads.

5. Molly Bolts These are heavy-duty anchors that consist of a metal sleeve that expands behind the drywall when the screw is tightened. Molly bolts are ideal for hanging heavy objects and can support significant weight, making them popular for mounting fixtures like cabinets and large mirrors.

drywall screw anchor types factories

Manufacturing of Drywall Screw Anchors

The production of drywall screw anchors involves several steps and considerations to ensure high quality and reliability. Factories specializing in manufacturing these anchors typically follow these processes

1. Material Selection The choice of material is crucial. Manufacturers often use plastic, steel, or a combination of both to produce anchors that can withstand varying weights and environmental conditions.

2. Design and Engineering Each type of anchor has a unique design tailored to its specific application. Engineers carefully design anchors to ensure they can handle the intended load without failing.

3. Molding and Machining For plastic anchors, injection molding is commonly used, while metal anchors may undergo processes like stamping and machining. This stage molds the anchors into their final shape.

4. Quality Control Rigorous quality testing is conducted to ensure that the anchors meet industry standards. This includes testing for load-bearing capacity and durability under stress.

5. Packaging and Distribution Once tested and approved, the anchors are packaged for shipping to retailers and wholesalers. Proper packaging ensures they remain intact during transportation and are easy to store.

Conclusion

Understanding the various types of drywall screw anchors and their manufacturing processes is vital for anyone involved in construction or home improvement. Choosing the right anchor for the job not only ensures safety and stability but also enhances the longevity of installed fixtures. As the demand for reliable anchoring solutions continues to grow, manufacturers are committed to producing innovative and robust products that meet the evolving needs of builders and homeowners alike.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

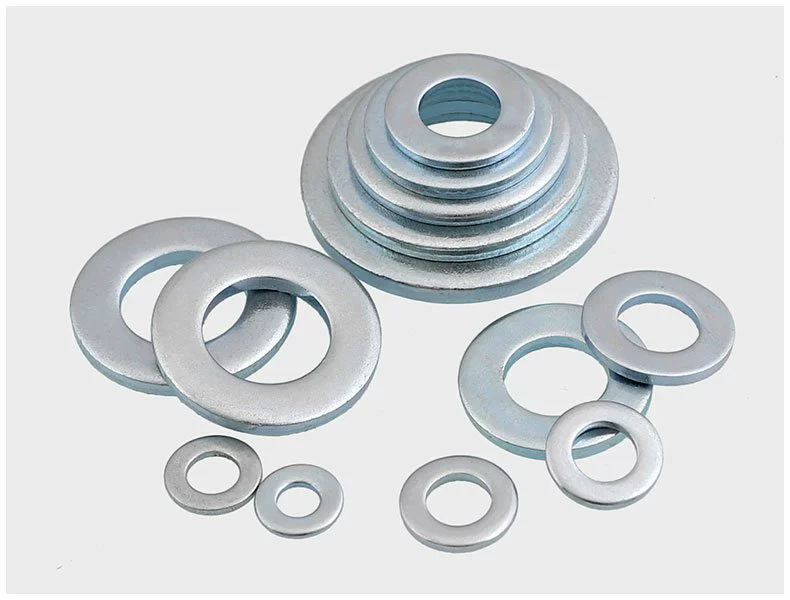

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024