Drywall Ceiling Installation Screw Placement Guide for Optimal Results

Understanding the Drywall Ceiling Screw Pattern

When it comes to installing drywall on ceilings, achieving a secure and aesthetically pleasing finish is paramount. One of the most crucial aspects of this process is the screw pattern used to attach the drywall to the framing. A proper drywall ceiling screw pattern not only ensures structural integrity but also helps prevent common issues like sagging and cracking over time.

Importance of Proper Screw Placement

The screw placement in drywall installation plays a significant role in how well the drywall holds up under various conditions. When screws are placed too far apart, or if there aren't enough screws, the drywall may sag or develop cracks. This is especially critical in ceiling applications, where gravity exerts a constant force on the material. A proper screw pattern enhances the overall strength of the installation and minimizes the risk of future problems.

Recommended Screw Pattern

The recommended screw pattern for drywall ceilings typically involves placing screws every 12 to 16 inches along the edges and in the field of the panels. For a standard 1/2-inch drywall, screws should be driven in at a distance of approximately 12 inches on the edges (the sides of the panel) and 16 inches apart in the central areas of the panel. This spacing helps distribute the weight effectively, ensuring that the drywall is firmly secured.

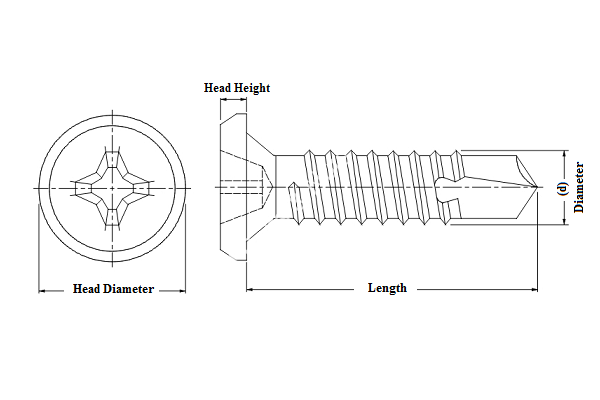

In addition to spacing, the depth at which the screws are driven is also critical. The screws should be countersunk just below the surface of the drywall paper without breaking through it. This will allow for smooth finishing and helps in avoiding any visible screw heads after paint is applied.

Laying Out the Drywall

Before securing the drywall, it's beneficial to lay out your panels in advance. Start with the longest wall and work your way across the ceiling. Ensure that the entire ceiling surface is covered and use the staggered joint technique when placing the panels. Staggered joints reduce the chances of cracking and create a more stable surface. For instance, in a room where one row of drywall ends at a particular point, the next row can begin halfway through the first panel, which significantly enhances the strength of the installation.

drywall ceiling screw pattern

Additional Tips for Success

1. Use the Right Tools Employing a drywall screw gun or a power drill with a drywall attachment can speed up the installation process while ensuring consistent depths and spacing.

2. Check for Level Before securing the drywall, use a level to ensure the panels are even. This is especially important in ceilings, where any unevenness will be more visible.

3. Secure Loose Spots If you notice any sagging or loose spots after the initial screw application, make sure to add screws to those areas. This will help reinforce the drywall and prevent future issues.

4. Pre-Drill In certain cases, pre-drilling the screw holes can help avoid any splitting, especially near edges.

5. Finishing Touches After installation, sand the joints and apply a good quality joint compound to achieve a smooth finish. This also helps hide any visible screw heads.

Conclusion

A well-executed drywall ceiling installation hinges on the screw pattern used. By maintaining recommended distances and ensuring thorough coverage, you can create a durable and attractive ceiling. Not only does a proper screw pattern enhance the longevity of the installation, but it also sets the foundation for a successful finishing job, ultimately leading to a polished and professional look in any space. Whether you're a seasoned contractor or a DIY enthusiast, understanding and implementing the right screw pattern is essential for any drywall project.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024