drill bit size for 10 self tapping screw product

Understanding Drill Bit Sizes for 10 Self-Tapping Screws

When it comes to securing materials together, self-tapping screws play a pivotal role in various applications, from constructing furniture to building metal structures. One of the essential elements in the effective use of these screws is selecting the correct drill bit size. This article aims to provide a clear understanding of the drill bit size needed for 10 self-tapping screws and its significance in ensuring a secure and efficient fastening process.

What are Self-Tapping Screws?

Self-tapping screws are specially designed to cut their own thread into the material they penetrate. This eliminates the need for pre-drilling in many situations, making them an efficient choice for quick assembly tasks. They are used in a wide range of materials, including wood, metal, and plastic. However, for optimal performance, it’s crucial to match the screw size with the appropriate drill bit.

Identifying 10 Self-Tapping Screws

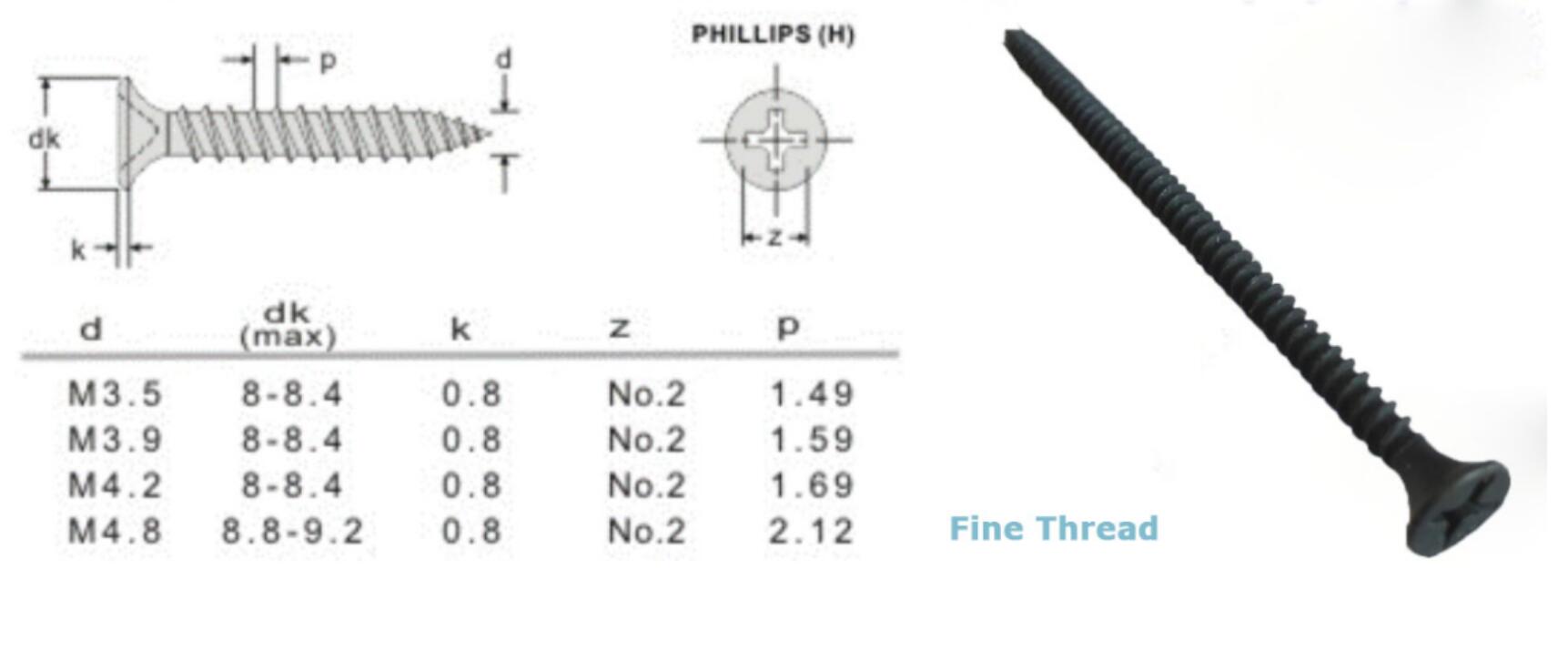

The 10 screw size refers to the diameter and length of the screw. Typically, 10 screws have a diameter of approximately 0.190 inches (4.83 mm). They are commonly used in various applications, including metal and wood assembly, electrical work, and automotive repairs. To ensure these screws perform effectively, using the right drill bit size is paramount.

Choosing the Right Drill Bit Size

For 10 self-tapping screws, the commonly recommended drill bit size is 7/64 inches or approximately 0.1094 inches (2.78 mm). This size allows the self-tapping screw to cut threads while providing enough material for a robust grip. Drilling with a bit that is too small can lead to excessive wear on the screw or even breakage, while using one that is too large may result in a loose fit and decreased holding power.

Factors to Consider

1. Material Type The type of material being fastened greatly affects the choice of drill bit and screw. For example, wood requires different considerations than metal. When fastening into metal, a pilot hole is often necessary to avoid damaging the screw or the material itself.

drill bit size for 10 self tapping screw product

2. Screw Length The length of the 10 screw can also impact the required drill bit size. Longer screws may need a slightly larger pilot hole to ensure they can drill through denser sections of material without excessive force.

3. Screw Coating Many self-tapping screws come with coatings intended to resist rust and corrosion. These coatings may alter the dimensions slightly, so it’s essential to confirm compatibility with the chosen drill bit.

Drilling and Installation Tips

When installing 10 self-tapping screws, ensure the material is stable and that any dust from drilling is removed from the area. It’s also wise to consider using a pilot hole, even though self-tapping screws can often be used without one, particularly in harder materials.

1. Drilling Start the drill at a low speed, increasing as necessary. This helps maintain control and prevents the material from splintering or cracking.

2. Screw Insertion Once the pilot hole is created, position the self-tapping screw straight in line with the hole and apply steady pressure.

3. Avoid Over-tightening It's important not to over-tighten the screw, as this can strip the threads you’ve just created or damage the material itself.

Conclusion

Understanding the proper drill bit size for 10 self-tapping screws is crucial for anyone engaged in construction or home improvement projects. A 7/64-inch drill bit typically provides the right size hole for effective screw insertion, allowing the self-tapping screw to function efficiently. By taking into account the type of material, length of the screw, and ensuring proper drilling techniques, you can achieve secure and long-lasting connections in your projects. Always remember, a little preparation can go a long way in ensuring success, making the right drill bit choice a fundamental step in the fastening process.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024