Custom Self-Drilling Screws for Various Applications and Industrial Needs

Understanding Custom Self-Tapping Screws A Comprehensive Guide

In the world of manufacturing and construction, the choice of fasteners can make a significant difference in the efficiency of a project. Among the various options available, self-tapping screws have gained substantial popularity due to their versatility and ease of use. However, when the standard options don’t fit the specific needs of a project, custom self-tapping screws become invaluable. This article will explore what custom self-tapping screws are, their benefits, and key considerations when choosing them for your applications.

What Are Self-Tapping Screws?

Self-tapping screws are specially designed fasteners that can create their own hole as they are driven into a material. This feature eliminates the need for pre-drilling in most applications, making them a preferred choice in various industries, including automotive, construction, and electronics. The design of self-tapping screws usually includes a sharp point and threads that are specifically engineered to cut into the material.

The Need for Customization

While standard self-tapping screws are available in various sizes and materials, there are instances where standard options fall short of meeting specific requirements. Custom self-tapping screws address this gap. They can be tailored based on factors like

1. Material Depending on the application, you may need screws made from stainless steel for corrosion resistance, or from brass for electrical conductivity. Custom options allow you to select the best material suited for your project.

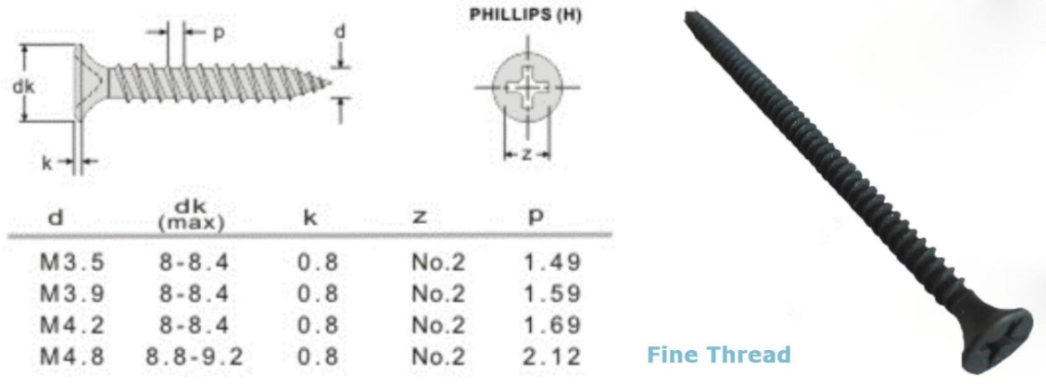

2. Size and Thread Design The size of the screw and the design of its threads can greatly affect its performance. Custom screws allow for modifications to the length, diameter, and thread pitch, ensuring you achieve the best fit for your specific materials.

3. Point Design The tip of a self-tapping screw can vary in design. Different point styles, such as sharp, blunt, or drill-pointed screws, can be chosen based on the type of material being used and the desired penetration depth.

4. Coatings and Finishes Custom screws can be coated or finished to improve corrosion resistance, aesthetic appeal, or adhesion properties. This customization can be crucial in environments exposed to harsh conditions or specific aesthetic standards.

5. Production Volume For projects requiring large quantities of screws, custom solutions can be designed to facilitate mass production, optimizing both cost and efficiency.

custom self tapping screw

Benefits of Custom Self-Tapping Screws

1. Tailored Solutions Custom screws meet precise application requirements, ensuring optimal performance. This aspect can enhance the durability and reliability of the overall assembly.

2. Cost Efficiency While custom fasteners can sometimes appear more expensive up-front, they can lead to cost savings in the long run. By reducing assembly times and preventing damage or failure due to incorrect fasteners, custom screws can be a more economical choice.

3. Improved Performance Custom self-tapping screws are engineered to enhance performance in specific material types and applications. This means fewer issues such as stripping or breakage during installation, leading to a more reliable end product.

4. Design Flexibility Customization allows designers and engineers to explore innovative fastening solutions that can contribute to unique project specifications or challenges.

Key Considerations

When opting for custom self-tapping screws, several factors should be taken into consideration

- Material Selection Ensure the chosen material aligns with the environment and application conditions. - Supplier Expertise Collaborate with a supplier who specializes in custom fasteners and can provide insights and expertise on your specific needs. - Testing It’s vital to conduct thorough testing of the custom screws once produced to ensure they meet performance expectations.

Conclusion

Custom self-tapping screws provide a flexible and efficient solution for various fastening applications. Their design enhances both functionality and reliability. By understanding the potential benefits and carefully weighing the parameters for customization, businesses can achieve significant improvements in their assembly processes and overall product quality. Whether in manufacturing or construction, investing in the right fasteners can lead to lasting positive results.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024