Custom M2 Self-Tapping Screw Size Specifications and Dimensions Guide

Understanding Custom M2 Self-Tapping Screw Dimensions

In the realm of mechanical engineering and manufacturing, the importance of selecting the right fasteners cannot be understated. Among the myriad of fasteners available, self-tapping screws have carved out a significant niche due to their unique ability to create their own mating threads in a material. This article will delve into the various dimensions and specifications of custom M2 self-tapping screws, a category that has gained popularity in a variety of applications ranging from electronics to automotive industries.

What are Self-Tapping Screws?

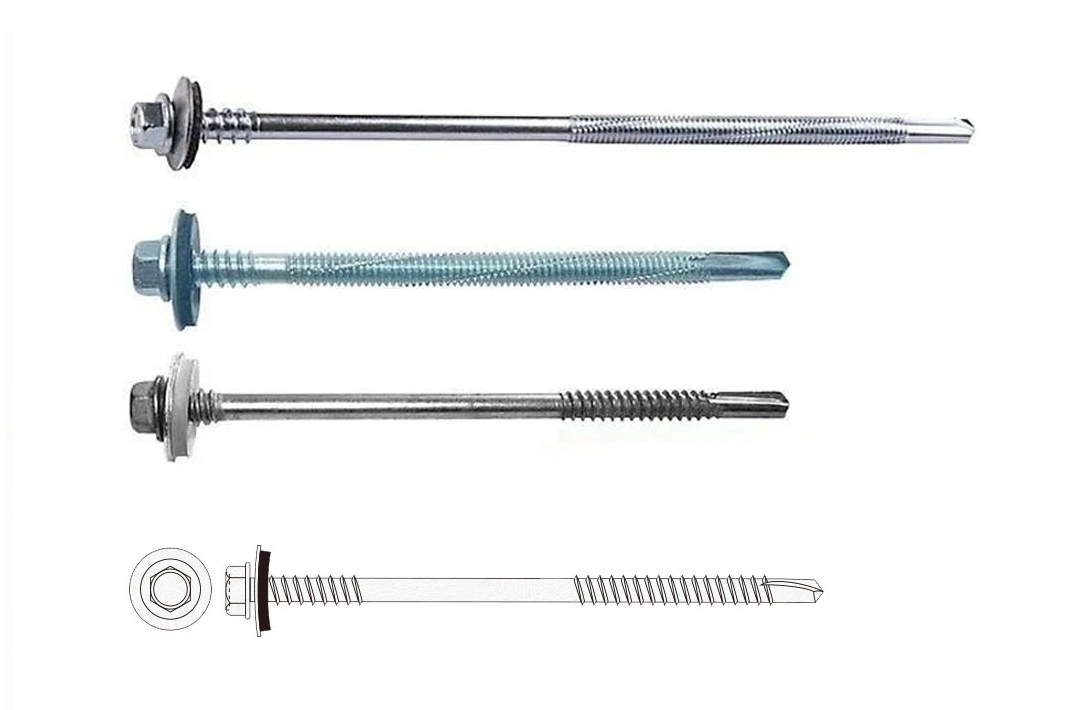

Self-tapping screws are designed to create their own hole as they are driven into the material. This feature saves time and enhances efficiency, reducing the need for pre-drilled holes. They are particularly useful in thin materials, where strength and reliability are critical. The design of self-tapping screws typically incorporates a sharp, pointed tip that allows for easier penetration into substrates, making them an ideal choice for assembly line applications.

The Significance of M2 Screws

The M denotes the metric thread standard, while 2 specifies the nominal diameter of the screw shaft in millimeters. Thus, an M2 screw has a shaft diameter of 2 mm. This size is commonly used in smaller assemblies, including electronic devices and model kits. The compact size allows for a high degree of precision and a minimal footprint, which is crucial in components where space is at a premium.

Key Dimensions of Custom M2 Self-Tapping Screws

When considering custom M2 self-tapping screws, several dimensions and specifications must be addressed

1. Length The length of the screw is a critical dimension and can vary based on application requirements. Custom lengths can range from a few millimeters to several centimeters, ensuring compatibility with the material thickness being utilized.

custom m2 self tapping screw dimensions

2. Head Type The head of the screw can come in various designs, including flat, pan, or round. Flat-headed screws allow for a flush finish, while pan heads offer a greater surface area for torque application. The choice of head type is often influenced by aesthetic considerations and functional requirements, including how the screw will sit against the surface of the material.

3. Thread Pitch The pitch of the screw refers to the distance between threads. For M2 screws, common pitches include 0.4 mm and 0.5 mm. A finer pitch can provide better gripping power, making it suitable for softer materials, while a coarser pitch typically works better with harder substrates.

4. Material and Coating The choice of material impacts the screw's strength, corrosion resistance, and overall performance. Common materials include steel, stainless steel, and plastics. Additionally, coatings such as zinc plating or powder coating can offer enhanced protection against environmental factors.

5. Driving Compatibility The type of drive (e.g., Philips, slotted, Torx) is also an essential feature. Different drive types affect the ease of installation and the torque applied during fastening. Custom screws may come with specific drive types to suit various tools and settings.

Benefits of Customization

Opting for custom M2 self-tapping screws enables manufacturers to tailor fasteners to their specific application needs. Customization can encompass dimensions, materials, and even specialized features, ensuring that the screws perform effectively under the unique conditions they will face. This not only enhances product reliability but can also lead to cost efficiencies in manufacturing and assembly.

Conclusion

Custom M2 self-tapping screws represent a versatile and essential component in modern manufacturing and assembly. Understanding their dimensions, features, and potential for customization facilitates informed decision-making, promoting enhanced product performance and longevity. As industries continue to evolve, the tailored use of such fasteners will remain critical in maintaining efficiency and quality in production processes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024