custom chipboard nail

Understanding Custom Chipboard Nails A Comprehensive Guide

In the world of woodworking, furniture production, and construction, the use of the right fasteners is crucial to ensuring the durability and strength of the finished product. Among the various types of fasteners available, chipboard nails have gained significant attention due to their unique design and effectiveness in securing chipboard materials. This article will take an in-depth look at custom chipboard nails, their features, advantages, and applications.

What Are Chipboard Nails?

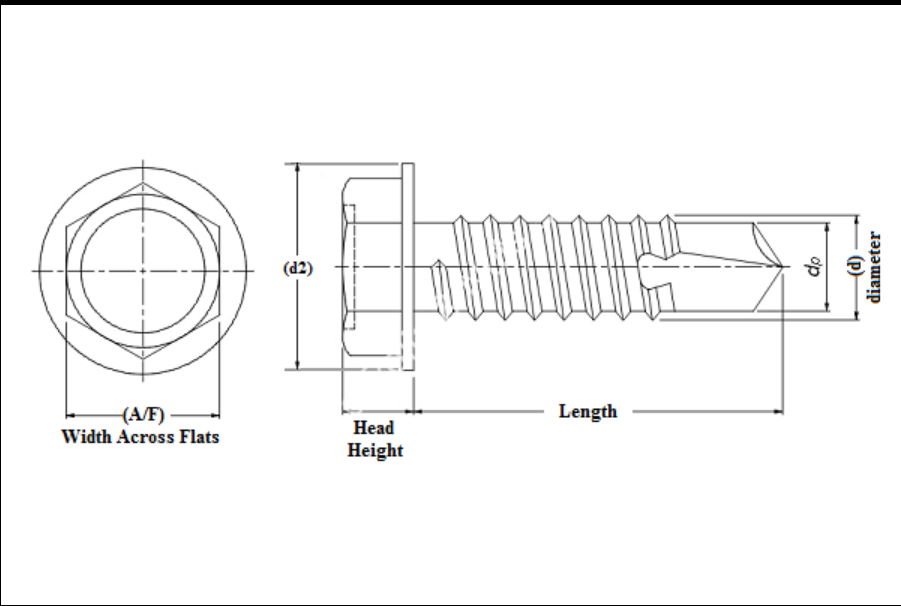

Chipboard nails are specialized fasteners designed specifically for use with chipboard, a manufactured wood product made from wood chips, sawmill shavings, or sawdust that is glued together. These nails are typically made from high-quality steel, which ensures they can endure the stresses associated with securing materials. The design of chipboard nails often includes a unique head shape and shank structure, enabling them to grip the material effectively and prevent pull-out.

Customization of Chipboard Nails

While standard chipboard nails are widely available, the option for custom chipboard nails presents numerous advantages, tailored to meet specific project requirements. Custom chipboard nails can be produced in various lengths, diameters, head shapes, and coating options. This customization allows manufacturers to select nails that best suit their chipboard thickness and density, thereby optimizing performance.

Certain projects may require nails that are resistant to corrosion; in such cases, manufacturer-specific coatings can be applied. Galvanized or stainless steel finishes are popular choices, especially for outdoor or high-humidity applications, as they extend the lifespan of the nails significantly.

The Advantages of Custom Chipboard Nails

1. Enhanced Performance Custom chipboard nails can be designed to provide superior holding power. This is particularly beneficial in furniture making, where durability and aesthetics are equally important.

custom chipboard nail

2. Design Flexibility By opting for custom nails, manufacturers have the flexibility to design products that cater to specific aesthetics or performance needs. This flexibility can differentiate products in a competitive market.

3. Cost-Effectiveness Ordering nails in bulk with custom specifications can lead to cost savings in the long run. Manufacturers can adjust the nail specifications according to the scale of production, reducing waste and improving operational efficiencies.

4. Specific Applications Different projects may demand unique characteristics from fasteners. Custom chipboard nails can be created to accommodate

- Heavy-duty Applications Nails meant for structural projects that require superior strength. - Aesthetic Considerations Nails designed to blend seamlessly with the finish of the furniture or cabinet work. - Eco-Friendly Options Manufacturers can choose materials and coatings that align with sustainable practices.

Applications of Custom Chipboard Nails

Custom chipboard nails find applications in various industries, including

- Furniture Manufacturing Used to assemble components such as tabletops, cabinets, and frames. - Construction Essential in building structures where chipboard is included in floors and walls. - DIY Projects Home enthusiasts often seek custom nails to ensure their projects meet specific design and functional standards.

Conclusion

Custom chipboard nails are an integral component in the world of woodworking and construction, providing tailored solutions that enhance the quality and durability of products. By understanding the unique features and benefits of these fasteners, manufacturers and DIY enthusiasts can make informed choices to improve their work. With the combination of innovation and customization, chipboard nails contribute significantly to the overall success of their applications, solidifying their position as an invaluable tool in various industries. Whether for a large-scale manufacturing operation or a weekend woodworking project, investing in the right custom chipboard nails can make all the difference.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024