Custom 2 Inch Flat Washer for Various Applications and Durable Performance

Understanding Custom 1 2 Inch Flat Washers A Comprehensive Guide

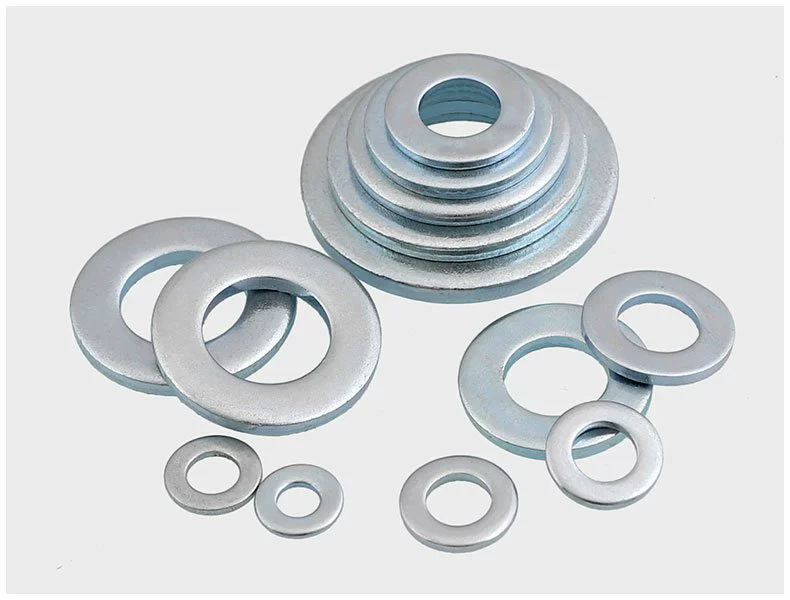

In the realm of hardware and construction, flat washers are often overlooked yet indispensable components. Among the various types of washers available, the custom 1 2 inch flat washer stands out due to its unique specifications and versatile applications. This article will explore what flat washers are, the significance of custom sizes, the materials used, and how these washers are applied across different industries.

What is a Flat Washer?

A flat washer is a disc-shaped piece of hardware typically used to distribute the load of a threaded fastener, such as a bolt or screw. The primary function of a washer is to prevent the fastener from pulling through the material being fastened, providing stability and reducing wear. Additionally, washers protect surfaces from damage and corrosion, making them vital in various mechanical applications.

The Importance of Custom Sizing

While standard washers come in predefined sizes, custom washers, like the 1 2 inch flat washer, cater to specific requirements that standard sizes may not meet. Custom sizes are crucial in specialized machinery, construction projects, and unique assembly needs where precise measurements are necessary for optimal performance.

For instance, a custom 1 2 inch flat washer can be tailored to fit specific bolt sizes, hole diameters, or even unique shapes depending on the installation scenario. This tailoring ensures a snug fit, reducing the risk of loosening and promoting longevity in applications where movement, vibration, or harsh environmental conditions are present.

Materials Used in Washers

Flat washers can be made from a variety of materials, each offering different properties suited for specific applications. Common materials include

1. Steel One of the most common materials for flat washers, steel offers strength and durability. It is often zinc-coated or plated to prevent rust and corrosion. 2. Stainless Steel For applications where corrosion resistance is paramount, stainless steel washers are an excellent choice. They are ideal for outdoor projects, marine applications, and any situation exposed to moisture.

3. Plastic Nylon or other plastics can be used for lightweight applications where corrosion might be an issue. They also provide excellent insulation in electrical applications.

custom 1 2 inch flat washer

Selecting the appropriate material for a custom 1 2 inch flat washer is crucial, as it directly affects the performance and durability of the fastener assembly.

Applications Across Industries

Custom 1 2 inch flat washers find their applications across various sectors, demonstrating their versatility. Here are a few notable examples

- Construction In building structures, these washers distribute the load of bolts and screws securely, ensuring that elements like beams, walls, and frames are held firmly in place.

- Automotive In vehicle manufacturing and repair, flat washers are essential for securing components in engines, transmissions, and suspensions, ensuring safety and performance.

- Electronics In electronic devices, washers are often used to create insulation between metal parts and prevent electrical shorts, safeguarding the device's functionality.

- Aerospace The aerospace industry relies on custom flat washers for secure fastening in aircraft components, where precision and reliability are of utmost importance due to safety regulations.

- Home Improvement DIY enthusiasts and contractors use flat washers in furniture assembly, plumbing, and various home repairs, showcasing their role in everyday household applications.

Conclusion

Custom 1 2 inch flat washers may be small components, but their role in various industries is undeniably significant. Their ability to be tailored to specific needs, combined with the diverse materials available, makes them indispensable in ensuring the stability and longevity of fasteners across numerous applications. As technology and engineering continue to advance, the demand for precision-made hardware like custom flat washers is likely to grow, further solidifying their importance in construction, manufacturing, and DIY projects alike.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024