custom 1 1 4 flat washer

The Importance of Custom Flat Washers in Various Industries

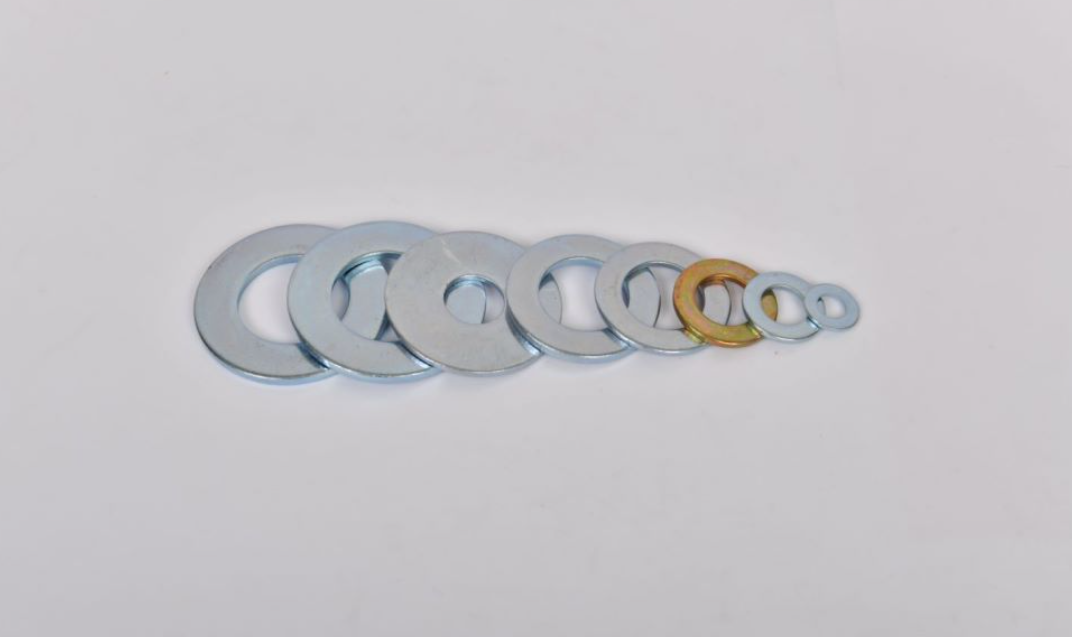

Flat washers are essential components in numerous applications across various industries. Often overlooked, these small discs play a critical role in distributing loads, preventing loosening, and protecting surfaces. Among the myriad types of washers available, custom flat washers are particularly significant for engineering and manufacturing processes, as they offer the versatility needed to meet specific requirements.

Understanding Flat Washers

A flat washer is typically a thin, round plate with a hole in the center, designed to be installed alongside a fastener like a bolt or screw. The primary functions of flat washers include load distribution, providing a smooth surface for fastening components, and preventing damage to the surfaces being joined. Washers also serve as spacers, sealing surfaces, or anti-friction devices depending on the application. While they may seem simple, the material, size, and finish of washers can drastically affect their performance in various environments.

The Need for Customization

Standard flat washers may meet the needs of many applications; however, there are instances when specific projects demand customized solutions. Custom flat washers can be designed to exact specifications to fit unique fastener sizes, comply with specific load tolerances, or accommodate unique environmental factors such as temperature and corrosion resistance.

In industries such as aerospace, automotive, and construction, the precision and reliability of components are paramount. Custom flat washers can be tailored to fulfill these stringent demands. For example, a manufacturer may require stainless steel flat washers for their resistance to corrosion and high strength, while another might need rubber washers that provide cushioning and vibration dampening for electronic devices.

Applications Across Industries

custom 1 1 4 flat washer

The applications for custom flat washers are extensive. In construction, these washers ensure that heavy framing materials are securely fastened and can distribute loads across larger areas to prevent failure. In the automotive industry, custom washers help ensure that critical engine components remain secure despite the constant vibration and movement experienced during operation.

In the electronics sector, custom flat washers help maintain the integrity of connections in electronic devices. They can be designed to be non-conductive, preventing short circuits, or designed with special coatings to improve their performance under high temperatures or humid conditions. The medical field also relies on custom washers, as precise engineering and materials are crucial for devices and equipment that must meet strict safety and regulatory standards.

Manufacturing and Material Considerations

When manufacturing custom flat washers, several variables come into play, including material selection, production methods, and finishing options. Common materials include various grades of steel, aluminum, brass, plastic, and rubber. Each material offers distinct advantages depending on the application—for instance, high-strength steel is ideal for heavy machinery, while plastic washers might be preferred for lightweight applications to avoid adding unnecessary weight.

Moreover, the manufacturing process can include stamping, machining, or even 3D printing, allowing for flexibility in design and production volumes. Surface finishes, such as anodizing, plating, or powder coating, can enhance corrosion resistance, aesthetics, and durability, further tailoring the washers to their intended applications.

Conclusion

In conclusion, custom flat washers are indispensable components across many industries, providing essential functions that contribute to the integrity and effectiveness of various systems. By understanding the need for customization and its implications in manufacturing, businesses can ensure they are selecting the right washers for their specific needs. As technology advances and industries become more specialized, the demand for custom flat washers will undoubtedly continue to grow, highlighting their critical role in modern engineering and manufacturing processes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024