custom flat washer head screws

Understanding Custom Flat Washer Head Screws

In the world of engineering and manufacturing, fasteners play a crucial role in ensuring the integrity and functionality of assemblies. Among these fasteners, custom flat washer head screws are gaining popularity due to their unique design and versatile applications. This article will delve into what custom flat washer head screws are, their benefits, and their various applications.

What Are Custom Flat Washer Head Screws?

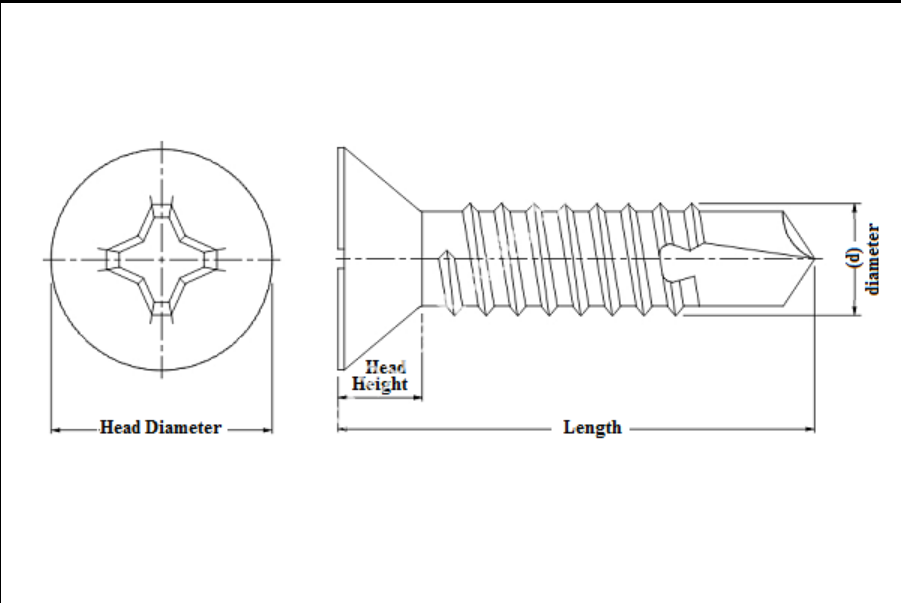

Custom flat washer head screws are fasteners designed with a built-in flat washer integrated into the head of the screw. This innovative design provides several advantages over traditional screws, including better load distribution and enhanced resistance to pull-through in softer materials. The flat washer, in this context, acts to distribute the bearing load over a broader area and also serves to prevent damage to the surface being fastened.

These screws can be manufactured in a variety of materials, including stainless steel, carbon steel, and even aluminum, depending on the specific requirements of the application. The ability to customize the size, threading, and material makes these screws suitable for various operational environments.

Benefits of Custom Flat Washer Head Screws

One of the primary benefits of custom flat washer head screws is their versatility

. They can be tailored to fit specific projects, ensuring that they meet the exact specifications required for the assembly. This customization can extend to length, diameter, thread type, and even the type of finish applied to the screw.Additionally, the integrated washer reduces the need for separate components, streamlining the assembly process. This not only saves time during installation but also reduces the chances of losing individual washers or screws. As a result, manufacturers can significantly enhance their operational efficiency while minimizing the likelihood of assembly errors.

custom flat washer head screws

Another advantage is the improved performance in high-stress applications. The flat washer head helps to distribute forces more evenly, thereby increasing the screw's holding power and reducing the risk of failure under load. This makes them particularly useful in industries such as automotive, aerospace, and construction, where safety and reliability are paramount.

Applications of Custom Flat Washer Head Screws

Custom flat washer head screws are used in a myriad of applications. In the automotive industry, they are commonly found fastening components such as engine parts, chassis, and body panels. Their durability under various environmental conditions makes them suitable for both interior and exterior applications.

In aerospace, the need for lightweight yet robust fasteners is critical. Custom flat washer head screws provide an effective solution, ensuring that components remain securely fastened even under extreme conditions.

Moreover, architectural installations benefit from the aesthetically pleasing appearance of these screws, particularly when head finishes are customized to match surrounding materials. This is increasingly important in modern designs where both functionality and appearance matter.

Conclusion

In conclusion, custom flat washer head screws represent a valuable advancement in fastener design, combining versatility, efficiency, and reliability. By understanding the benefits and applications of these screws, manufacturers can make informed decisions that enhance their products and assemblies. As the demand for customized solutions continues to grow, the role of these innovative fasteners will undoubtedly become even more significant in various industries.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024