Custom Flat Sealing Washers for Superior Sealing Solutions in Various Applications and Industries

Custom Flat Sealing Washers An Essential Component in Mechanical Applications

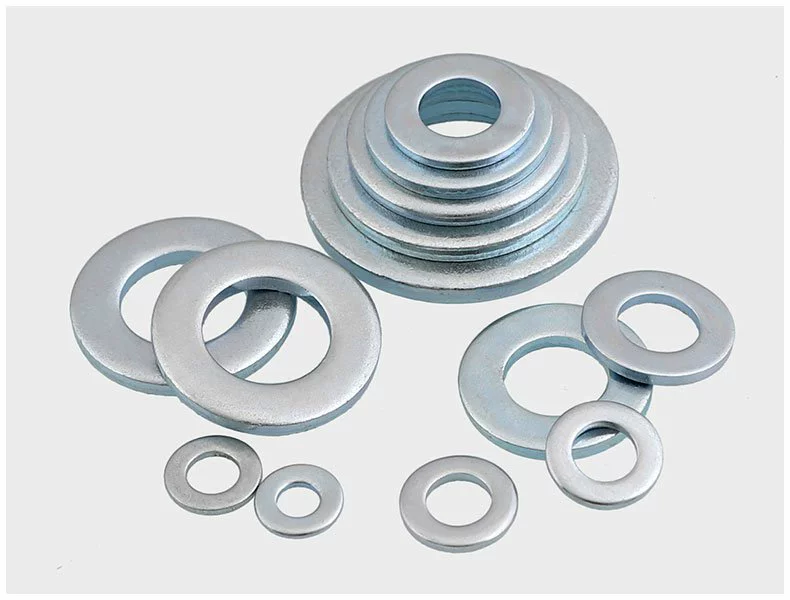

Flat sealing washers are essential components utilized in various mechanical and construction applications. These simple yet effective devices serve a crucial purpose to distribute the load of fasteners, prevent leakage, and minimize the chances of damage to materials. In this article, we will delve into the significance of custom flat sealing washers, their applications, materials used, and the benefits they offer in various industries.

Importance of Flat Sealing Washers

Flat sealing washers provide a surface that helps create a seal between two components, ensuring that fluids or gases do not leak. They act as a barrier against environmental conditions, thus protecting sensitive components from corrosion or damage. Flat sealing washers are especially critical in applications involving high pressure or temperature changes, where the integrity of the seal is paramount.

The Need for Customization

While many standard flat sealing washers are available on the market, there are numerous situations where custom washers are necessary. Customization allows for specific dimensions, materials, and designs tailored to meet the unique requirements of an application. For instance, in aerospace applications, where precision and reliability are crucial, customized flat sealing washers can be engineered to withstand extreme conditions and specific tolerances.

Applications Across Industries

Custom flat sealing washers find applications in a broad range of industries, including automotive, aerospace, construction, and manufacturing.

1. Automotive Industry In vehicles, flat sealing washers are commonly used in engines, transmissions, and various other assemblies. They help ensure that fluids remain contained, preventing costly leaks and maintaining optimal performance.

2. Aerospace In the aerospace industry, custom flat sealing washers are vital for their ability to withstand extreme conditions. They are designed to endure high pressures and temperatures, ensuring that aircraft systems operate safely and efficiently.

3. Construction In construction applications, sealing washers are integral to water and gas pipelines. They provide a reliable seal to prevent leaks, which is essential for infrastructure integrity and safety.

custom flat sealing washer

4. Manufacturing Many manufacturing processes require precise and reliable sealing solutions. Custom flat sealing washers can be designed to fit specialized machinery, contributing to the efficiency and safety of production lines.

Material Considerations

When manufacturing custom flat sealing washers, the choice of material is critical. Common materials include rubber, plastic, metal, and composite materials.

- Rubber Washers They provide excellent resistance to moisture and chemicals, making them suitable for a wide range of applications.

- Metal Washers Often used in high-strength applications, metal washers can withstand significant loads and temperatures, making them ideal for automotive and aerospace sectors.

- Plastic Washers Lightweight and cost-effective, these washers are useful in applications where corrosion resistance is crucial.

- Composite Materials These are increasingly popular due to their durability and resistance to wear and tear, making them suitable for both high-performance and standard applications.

Benefits of Custom Flat Sealing Washers

Investing in custom flat sealing washers brings several advantages. Firstly, they ensure a precise fit for your specific application, enhancing the overall performance and reliability of the components. Secondly, custom washers can be designed to meet stringent industry standards, ensuring compliance and safety. Finally, these washers can ultimately reduce maintenance costs and downtime by preventing leaks and other failures.

Conclusion

In summary, custom flat sealing washers play a vital role in various industries, providing essential sealing solutions that enhance the performance and reliability of mechanical systems. By investing in customized options, businesses can ensure they meet their unique requirements while benefiting from the enhanced capabilities of tailored washers. As industries continue to evolve, the demand for innovative sealing solutions will undoubtedly grow, and custom flat sealing washers will remain at the forefront of this essential niche.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024