Feb . 20, 2025 04:50

Back to list

din125 plain washer flat washer

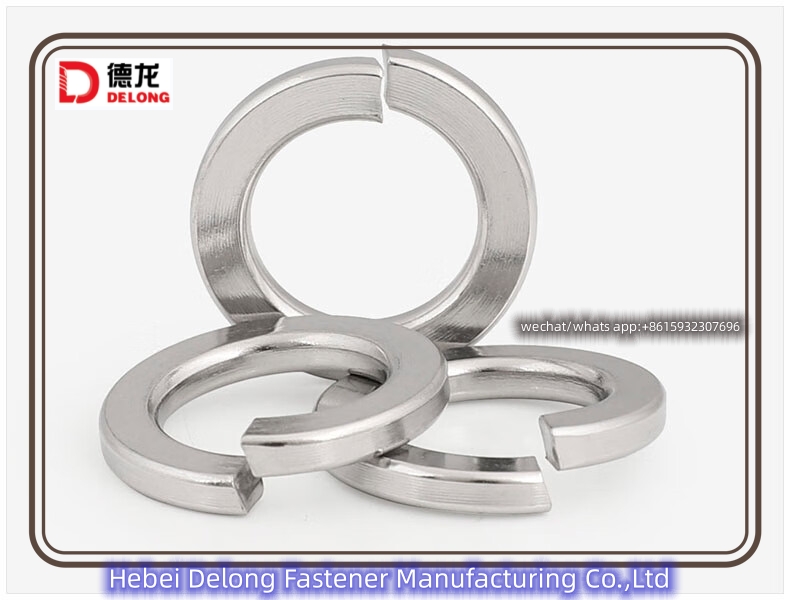

Curved disc spring washers, also known as Belleville washers or conical washers, are vital components in various engineering and industrial applications. These mechanical marvels are not just simple washers; they provide unique solutions by meeting specific engineering challenges.

When selecting a curved disc spring washer for a specific application, it's crucial to consider factors such as load requirement, deflection needs, and the working environment. Partnering with a reputable manufacturer can provide guidance and assurance of quality. Advanced manufacturing techniques and rigorous testing protocols ensure that these washers meet and exceed industry standards. Industry experts and engineers often advocate for curved disc spring washers due to their reliability and efficiency. In comparison to other fastening solutions, they offer a compelling advantage by reducing maintenance costs and downtime. Their ability to maintain tension without the need for retightening makes them an economical choice for many industries. For anyone looking to enhance structural integrity in engineering applications, curved disc spring washers provide an unmatched solution. Their expert design and tested durability make them a key player in ensuring safety and performance. As technology advances, the role of these washers continues to expand, making them a cornerstone in innovative engineering solutions. In conclusion, curved disc spring washers are not merely a component; they are a sophisticated tool essential for achieving optimal functionality in engineering projects. Bridging the gap between simple mechanical solutions and complex engineering demands, they embody the Experience, Expertise, Authoritativeness, and Trustworthiness crucial for modern engineering challenges.

When selecting a curved disc spring washer for a specific application, it's crucial to consider factors such as load requirement, deflection needs, and the working environment. Partnering with a reputable manufacturer can provide guidance and assurance of quality. Advanced manufacturing techniques and rigorous testing protocols ensure that these washers meet and exceed industry standards. Industry experts and engineers often advocate for curved disc spring washers due to their reliability and efficiency. In comparison to other fastening solutions, they offer a compelling advantage by reducing maintenance costs and downtime. Their ability to maintain tension without the need for retightening makes them an economical choice for many industries. For anyone looking to enhance structural integrity in engineering applications, curved disc spring washers provide an unmatched solution. Their expert design and tested durability make them a key player in ensuring safety and performance. As technology advances, the role of these washers continues to expand, making them a cornerstone in innovative engineering solutions. In conclusion, curved disc spring washers are not merely a component; they are a sophisticated tool essential for achieving optimal functionality in engineering projects. Bridging the gap between simple mechanical solutions and complex engineering demands, they embody the Experience, Expertise, Authoritativeness, and Trustworthiness crucial for modern engineering challenges.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News