Comprehensive Guide to SAE Flat Washer Dimensions and Sizing for Exporters

Understanding SAE Flat Washer Size Chart for Exporters

When it comes to fastening applications, flat washers play a pivotal role in distributing loads, reducing friction, and preventing damage to surfaces. For exporters dealing in fasteners, particularly in the SAE (Society of Automotive Engineers) category, understanding the size chart for flat washers is crucial for ensuring the right products are provided to customers across various industries.

What Are SAE Flat Washers?

SAE flat washers are circular discs with a hole in the center, used alongside a nut and bolt to create a stronger hold by distributing the load generated by the fastened assembly. They are commonly made from materials like steel, stainless steel, and plastics, catering to different application needs and environmental conditions.

Importance of Size Charts

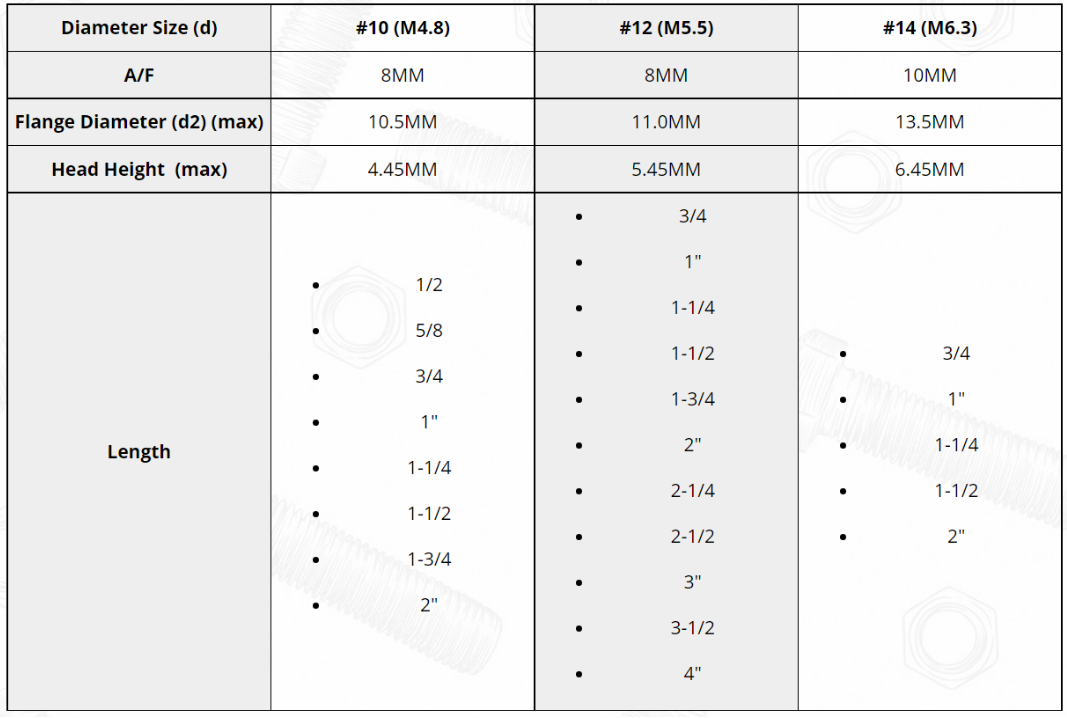

For exporters, having a clear and accessible size chart is essential. It helps in selecting the right flat washer based on the specifications required by the end users. The SAE flat washer size chart typically includes dimensions such as inner diameter, outer diameter, and thickness, enabling exporters to ensure they meet the exact requirements of various applications.

Knowing the sizes also helps prevent issues such as over-tightening, which can lead to failure in the fastening system. Therefore, a meticulous look at the size chart is indispensable for performance and safety.

Standard Sizes of SAE Flat Washers

The SAE flat washer size chart typically lists multiple standard sizes. For instance, sizes can range from very small (like 1/4 inch) to larger sizes (such as 1 inch or greater). Key dimensions in the chart may include

sae flat washer size chart exporters

- Inner Diameter (ID) This is the diameter of the hole and must fit the bolt or screw being used. - Outer Diameter (OD) This is the total diameter of the washer, which helps in load distribution. - Thickness The thickness of the washer can impact its strength and performance.

Exporters need to be aware of the specific applications where different sizes will be installed, whether in automotive, construction, or machinery applications, and ensure their products are compliant with the corresponding standards.

Material and Finish Considerations

Exporters should also pay attention to material choices and finishes included in the size chart. Common materials like hot-dipped galvanized steel, zinc-plated steel, and stainless steel offer varying levels of corrosion resistance and durability, which can be critical depending on the application environment.

Also, surface finishes can enhance performance; for instance, a yellow zinc finish is often used for added corrosion resistance compared to a standard zinc coating.

Conclusion

In conclusion, understanding the SAE flat washer size chart is imperative for exporters in the fastener industry. Not only does it help in providing the right products to customers, but it also ensures that applications perform safely and effectively. With accurate knowledge of dimensions, materials, and finishes, exporters can cater to a wide array of industries and meet diverse fastening needs.

As global markets continue to evolve, and with advancements in manufacturing processes, keeping abreast of the latest standards and sizes in flat washers will enhance the competitiveness of exporters. Whether dealing with automotive industries or construction sectors, having an intimate acquaintance with the SAE flat washer size chart is a valuable asset for any exporter.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024