Common Causes of Drywall Screw Pops in New Construction and Effective Solutions to Prevent Them

Addressing Drywall Screw Pops in New Construction Products and Solutions

In the realm of new construction, drywall installation is an essential phase that dictates the overall aesthetics and functionality of a space. However, regardless of the craftsmanship involved, issues can arise over time—one of which is drywall screw pops. This common phenomenon occurs when screws used to attach drywall to framing materials become loose or pull away from the wall. The end result is unsightly bumps or dimples in the finished surface, contributing to an imperfect appearance. In this article, we will explore the causes of drywall screw pops and highlight several products and solutions that can help mitigate these issues in new construction projects.

Understanding the Causes

Drywall screw pops are often caused by several factors 1. Moisture and Humidity Changes New homes often experience fluctuations in humidity as materials settle and cure. When wood framing dries out, it can shrink, leading to screws being pulled from the drywall. 2. Improper Installation If screws are not driven to the appropriate depth, or if the wrong type of screws are used, it can contribute to premature popping. 3. Temperature Changes Similar to humidity, seasonal temperature changes can cause the materials in walls to expand and contract, which can lead to screws loosening over time.

Recognizing these causes is the first step toward preventing screw pops in new construction.

Recommended Products and Solutions

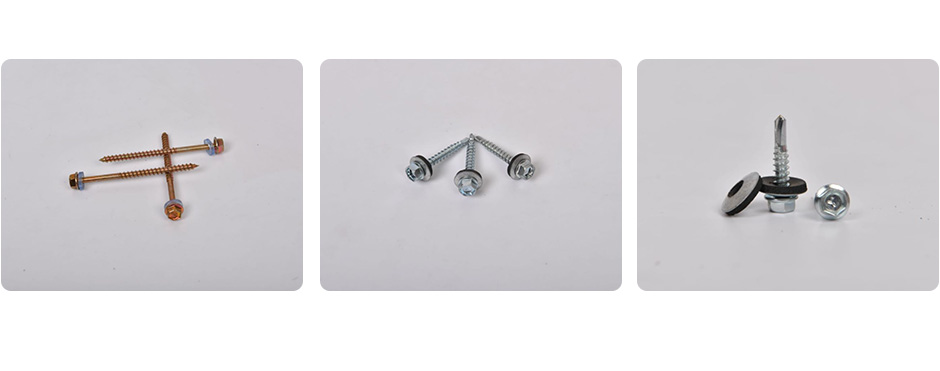

1. Use of Quality Drywall Screws One of the simplest preventive measures is to utilize high-quality drywall screws designed for the specific weight and type of drywall being installed. For instance, using coarse-thread screws for wood framing promotes better grip.

drywall screw pops new construction products

2. Screw Depth Guide Employing a screw depth guide can ensure that screws are driven to the correct depth without penetrating too deep into the drywall, which can risk damaging the board itself. This tool helps minimize the chance of installation errors related to screw placement.

3. Adhesive Solutions Some professionals advocate for the use of construction adhesive in addition to screws. By applying adhesive between the drywall and framing, you can create a stronger bond that counters the movement of framing materials. This dual approach can significantly reduce the incidence of screw pops.

4. Moisture-Resistant Drywall In areas prone to high humidity, such as bathrooms or basements, it is advisable to use moisture-resistant drywall products, often referred to as green board or cement board. These materials are less susceptible to the problems associated with moisture and can enhance longevity.

5. Flexible Joint Compounds When finishing drywall seams, using flexible joint compounds can help accommodate minor shifts in the framing materials. These compounds allow for slight movements without cracking and contribute to a smoother, more durable finish.

6. Regular Inspections and Maintenance Once construction is complete, homeowners and builders should schedule regular inspections to catch any potential issues early on. Addressing minor popping or dimpling immediately can prevent more significant repairs down the line.

Conclusion

Drywall screw pops may appear to be minor nuisances, but they can detract from the overall quality and appeal of newly constructed spaces. By understanding the causative factors and implementing preventative measures through quality products and techniques, builders and homeowners can significantly reduce the incidence of screw pops. Investing in quality materials and proper installation practices not only enhances the durability of the drywall but also ensures that the finished product aligns with the visual and structural standards expected in modern construction. In doing so, the long-term integrity of the beautiful spaces we create today will be preserved for years to come.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024