china self tapping screw sizes explained

Understanding China Self-Tapping Screw Sizes

Self-tapping screws are essential components in various construction and manufacturing applications, primarily used for fastening materials without the need for pre-drilled holes. In recent years, the popularity of self-tapping screws made in China has surged due to their affordability and reliability. However, understanding the different sizes and specifications is crucial for professionals and DIY enthusiasts to ensure the right fit for their projects.

What Are Self-Tapping Screws?

Self-tapping screws are characterized by their ability to create their own hole as they are driven into a material, such as wood, metal, or plastic. They feature a sharp point and sometimes come with cutting threads that aid in slicing through the material, reducing the need for additional tools. In China, manufacturers produce a wide range of self-tapping screws to meet various needs, offering them in different materials, such as carbon steel, stainless steel, and alloys.

Size Specifications

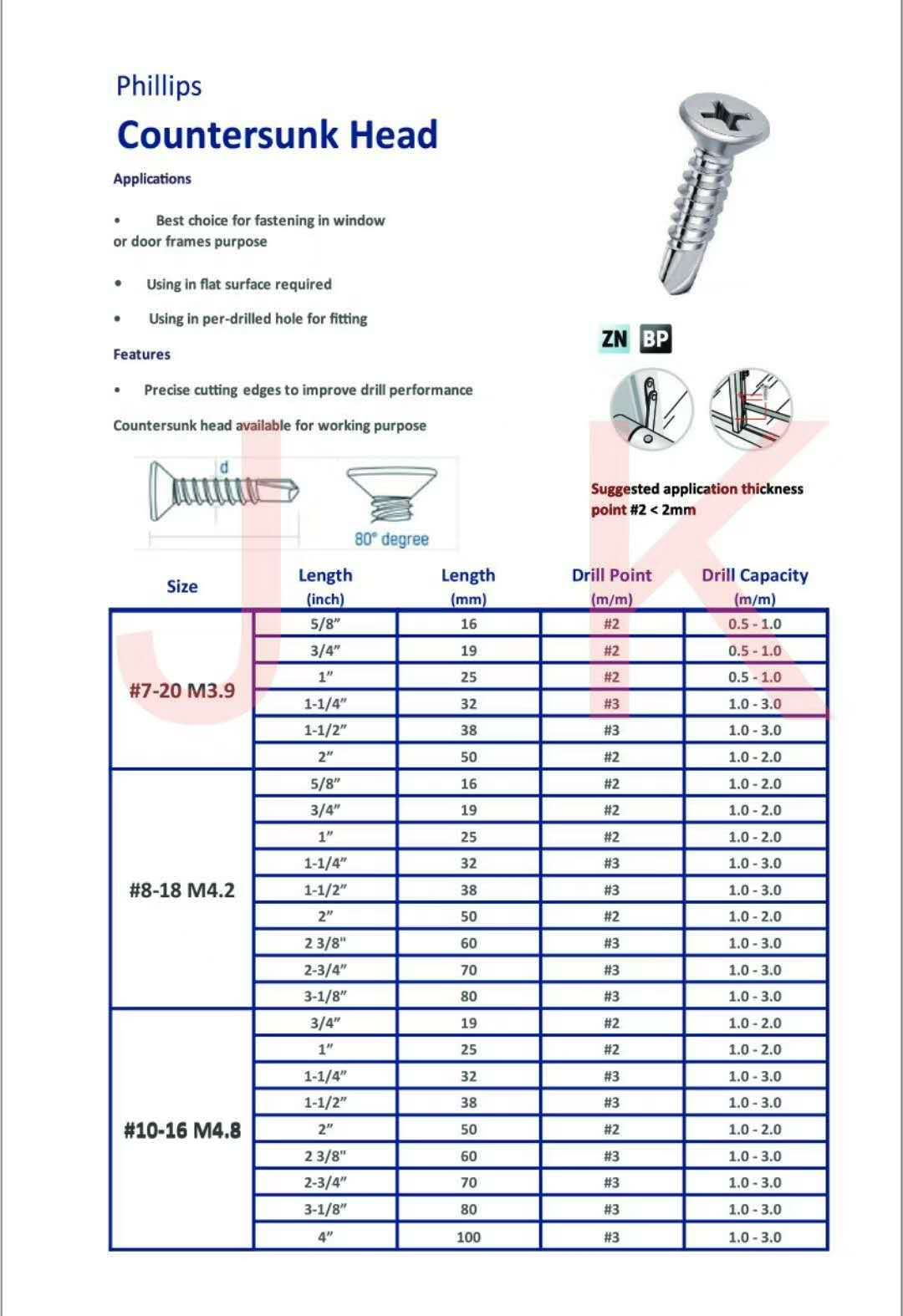

When choosing self-tapping screws, size is a critical factor. Typically, screw size is determined by several key dimensions diameter, length, and thread count. The sizes are often categorized according to the metric system (millimeters) or the imperial system (inches), depending on the standards used.

1. Diameter This is the width of the screw's shaft, usually measured in millimeters or inches. Common sizes for self-tapping screws include M3, M4, M5, and M6 in the metric system, while sizes like 6, 8, and 10 are prevalent in the imperial system. The diameter chosen should be appropriate for the materials being joined and the load they are expected to bear.

china self tapping screw sizes explained

2. Length Length is measured from the underside of the head to the tip of the screw. It is essential to choose a length that accommodates the thickness of the materials being fastened while ensuring that the screw penetrates sufficiently into the substrate for a secure hold. Typical lengths range from 12mm to 50mm or more, but custom lengths can also be ordered based on specific requirements.

3. Thread Count The thread count, or the number of threads per inch or per millimeter, affects how well the screw grips the materials. Coarse threads are common for soft materials, while fine threads offer better grip in harder materials. Understanding the thread type is vital for ensuring the screw performs optimally in its intended application.

Choosing the Right Screw

When selecting self-tapping screws from China, consider the material, coating, and specific applications. For instance, stainless steel screws may be ideal for outdoor use due to their resistance to corrosion, while galvanized screws offer good protection against rust and are suitable for various environments. Additionally, different head types (e.g., flat, pan, or hex) are available, which can affect the screw's performance depending on the tools used for driving the screw.

Conclusion

In summary, understanding the sizes and specifications of self-tapping screws is fundamental for successful fastening in any project. With the wide array of self-tapping screws produced in China, users should take the time to evaluate their specific needs based on diameter, length, and thread count. By considering all these factors, you can ensure optimal performance, longevity, and security in your applications, making self-tapping screws indispensable tools in both professional and DIY projects. Always consult with suppliers or manufacturers if you have any uncertainties regarding the best screws for your needs.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024