china high collar flat washer

Understanding China High Collar Flat Washers Essential Components in Engineering

In the world of engineering and manufacturing, the significance of small components is often underestimated. One such component is the flat washer, particularly the China high collar flat washer. This seemingly inconspicuous item plays a crucial role in ensuring the durability and reliability of various mechanical assemblies.

Understanding China High Collar Flat Washers Essential Components in Engineering

The term high collar refers to the elevated rim that encircles the hole of the washer. This design feature enhances the washer's capacity to hold the bolt head or nut securely in place, offering improved stability and resistance against shear forces. As a result, high collar flat washers are ideal for use in high-load environments, such as structural assemblies, automotive applications, and equipment manufacturing.

china high collar flat washer

Manufactured in China, high collar flat washers are available in various materials, including stainless steel, carbon steel, and brass. The choice of material largely depends on the specific requirements of the application, such as corrosion resistance, heat tolerance, and mechanical strength. For instance, stainless steel washers are widely used in outdoor applications or environments prone to moisture, providing excellent resistance to corrosion.

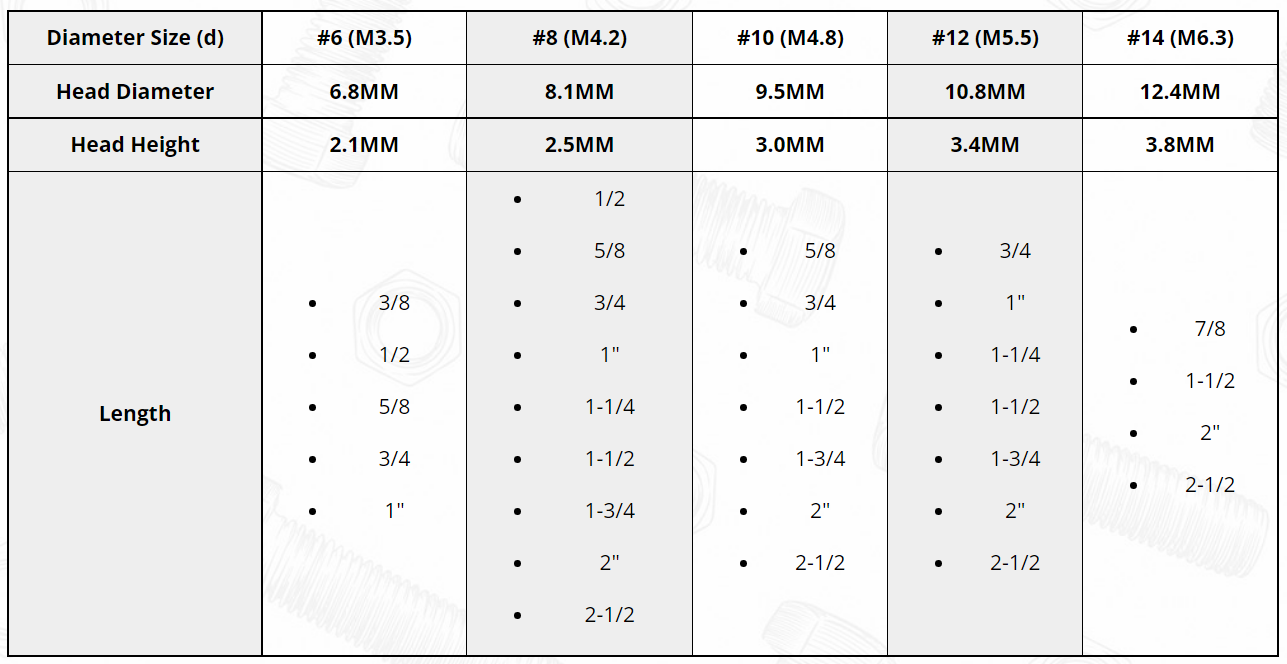

When selecting high collar flat washers, it is essential to consider factors such as the washer’s inner and outer diameters, thickness, and the specific load characteristics of the application. Proper sizing ensures optimal performance, preventing issues like bending or breaking under pressure. Additionally, the washer's surface finish can impact its effectiveness, as a smoother finish often leads to better load distribution.

China has emerged as a significant player in the global market for fasteners and washers, offering a vast array of products at competitive prices. Manufacturers in the region adhere to international standards and quality control measures, ensuring the reliability of their high collar flat washers. As industries increasingly focus on efficiency and reliability, the demand for high-quality components like these washers is steadily on the rise.

In conclusion, while high collar flat washers may be small in size, their importance in the engineering and manufacturing fields cannot be overlooked. Their unique design and robust performance make them essential for a myriad of applications, contributing to safer and more reliable mechanical assemblies. Understanding their features and benefits will undoubtedly aid engineers and manufacturers in making informed decisions when it comes to selecting the right components for their projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024